Internal combustion engine oil for crawler-type tank and preparation method of internal combustion engine oil

An internal combustion engine oil and track-type technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as the in-situ dynamic self-repair of the friction pair surface, and achieve good high-temperature oxidation resistance, low-temperature fluidity, and excellent viscosity-temperature Characteristics, the effect of small volatilization loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

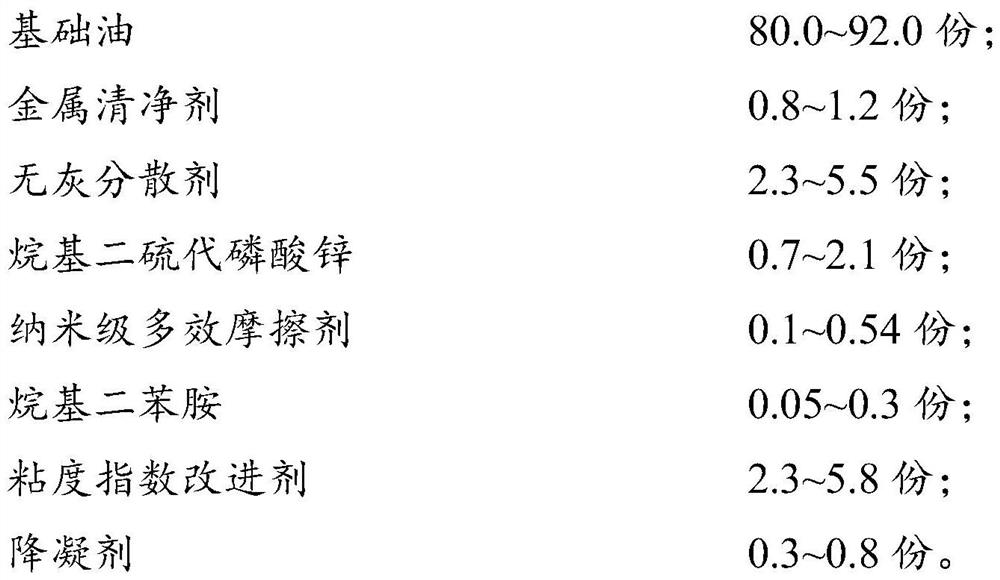

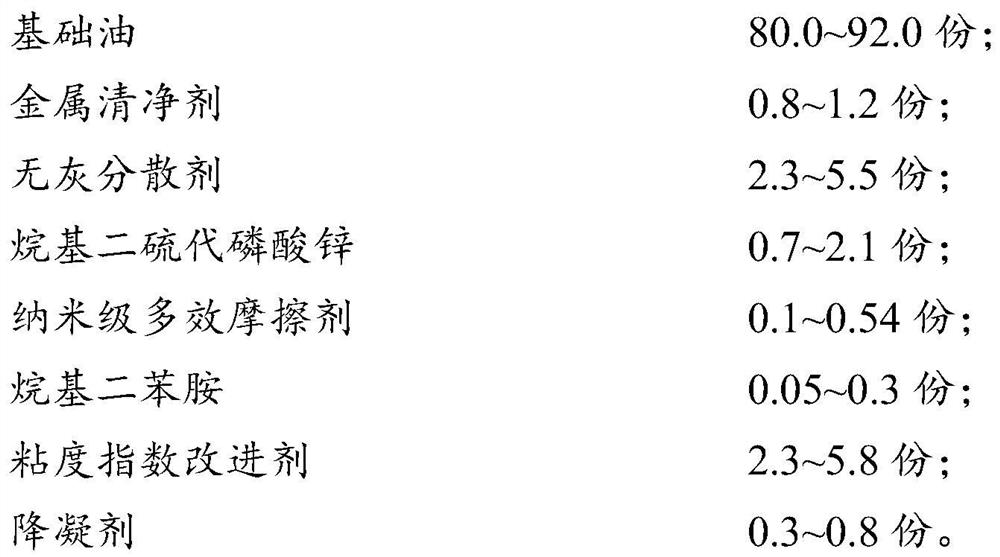

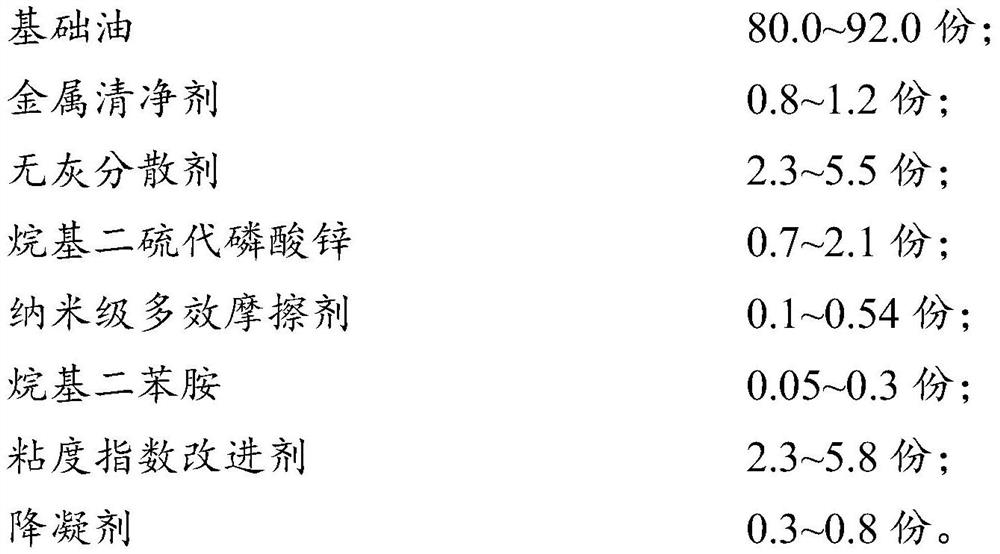

[0040] The invention provides a preparation method of internal combustion engine oil for crawler tanks, comprising the following steps:

[0041] 1) Preheat the base oil first, then add pour point depressant, viscosity index improver, alkyl zinc dithiophosphate, alkyl diphenylamine, metal detergent, ashless dispersant and mix to obtain a mixed oil;

[0042] 2) The finished oil is obtained after mixing the nano-scale multi-effect friction agent with the mixed oil.

[0043]In the present invention, the base oil preheating temperature is 55-65°C, preferably 57-62°C, more preferably 60°C.

[0044] In the present invention, in step 1), the mixing speed of the mixed oil is 400-600r / min, and the mixing time is 30-45min; preferably, the mixing speed is 450-550r / min, and the mixing time is 35-42min; More preferably, the mixing speed is 500r / min, and the mixing time is 40min.

[0045] In the present invention, in step 2), after mixing the nano-scale multi-effect friction agent and the ...

Embodiment 1

[0049] According to the proportion by weight, put 43 parts of polyalphaolefin Durasyn 166, 29 parts of Durasyn 180I and 13 parts of diester A1021 synthetic base oil into the reactor, start stirring, and heat to 65°C; put in 0.4 parts of T801, 5.5 parts of SVM5, 2.3 parts of alkyl zinc dithiophosphate, 0.3 part of alkyl diphenylamine, 1.2 parts of high alkali value calcium salicylate T115B, 3.0 parts of T154, stirred and mixed evenly at a rotating speed of 500r / min; Add 2.3 parts of nano-boron ceramic friction modifier, keep the original temperature at 600r / min and continue stirring for 40 minutes; pump it into a storage tank and let it stand for 1 hour to obtain the finished product 1. The physical and chemical properties of finished product 1 are shown in Table 2 below.

Embodiment 2

[0051] According to the proportion by weight, put 46 parts of polyalphaolefin Durasyn 166, 30 parts of Durasyn 180I and 12 parts of diester A1022 synthetic base oil into the reactor, start stirring, and heat to 65°C; put in 0.3 parts of T801, 5.5 parts of SVM5, 1.8 parts of zinc alkyl dithiophosphate, 0.2 part of alkyl diphenylamine, 0.9 part of high alkali value sulfurized calcium alkylphenate T115B, 1.7 parts of T154, stirred and mixed evenly at a rotating speed of 500r / min; Add 1.6 parts of nano-calcium hexadecyl borate, keep the original temperature at 600r / min and continue to stir for 40 minutes; pump it into a storage tank and let it stand for 1 hour to obtain the finished product 2. The physical and chemical properties of the finished product 2 are shown in Table 2 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com