Shock absorber oil composition

A technology of shock absorber oil and composition, which is applied in lubricating composition, petroleum industry, etc., and can solve the problems of anti-oxidation and anti-rust performance, anti-wear performance, anti-oxidation performance and viscosity-temperature performance that need to be improved. and other problems, to achieve excellent anti-friction and anti-wear properties, good anti-oxidation and anti-rust properties, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

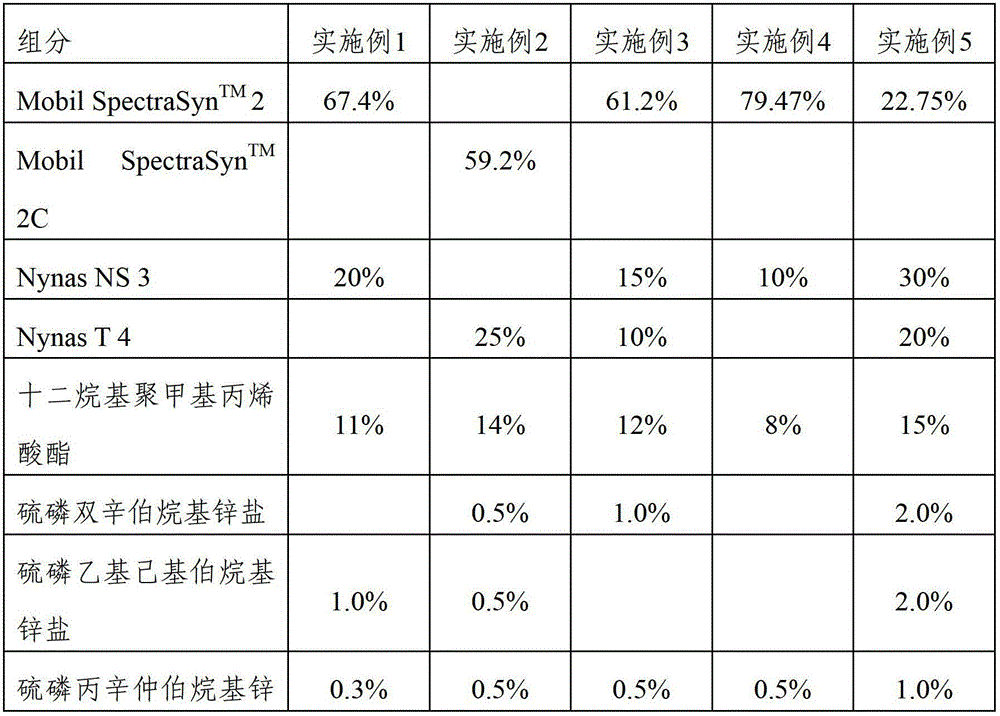

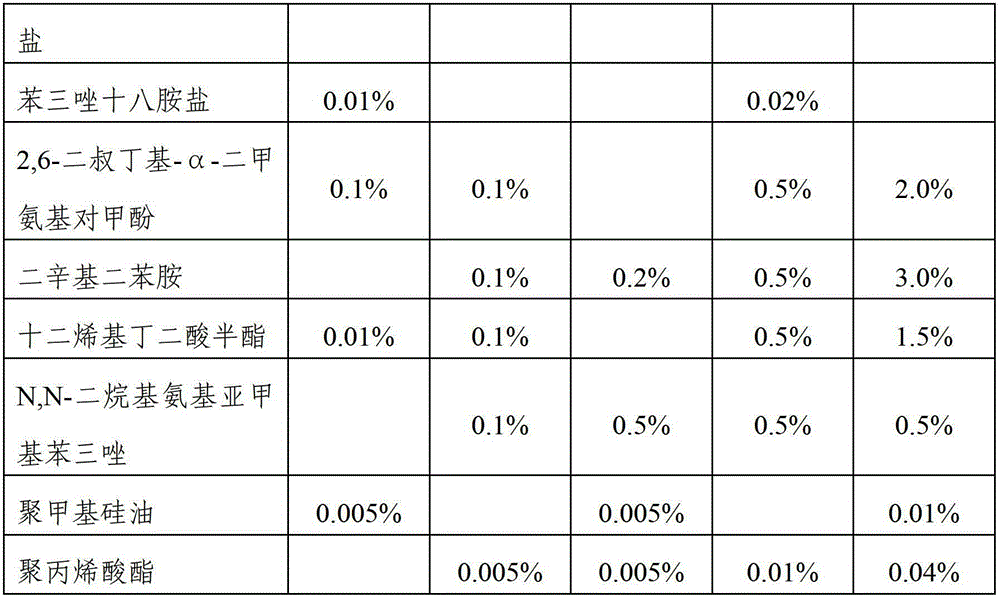

[0035] Prepare shock absorber oil of the present invention according to Table 1 formula.

[0036] The formula of table 1 embodiment 1~5

[0037]

[0038]

[0039]Among them, the pour point of Nynas NS 3 is -65°C, the content of dicycloalkanes is 45%, the content of tricycloalkanes is 27%, and the content of total naphthenes is 88%; the pour point of Nynas T 4 is -65°C, and the content of dicycloalkanes is 44%. The tricycloalkane content is 26%, and the total cycloalkane content is 85%; dodecyl polymethacrylate is selected from RohMaxVX 7-310; phosphobisoctyl zinc salt is selected from T203 of Liaoning Tianhe Fine Chemical Factory; The primary alkyl zinc salt of phosphoethylhexyl is selected from RheinChemieRC3080; the secondary primary alkyl zinc salt of thiophosproxine is selected from T205 of Liaoning Tianhe Fine Chemical Factory; the octadecylamine salt of benzotriazole is selected from T406 of Nanjing Ningjiang Chemical Factory; 2, 6-Di-tert-butyl-α-dimethylamino-p-...

Embodiment 4

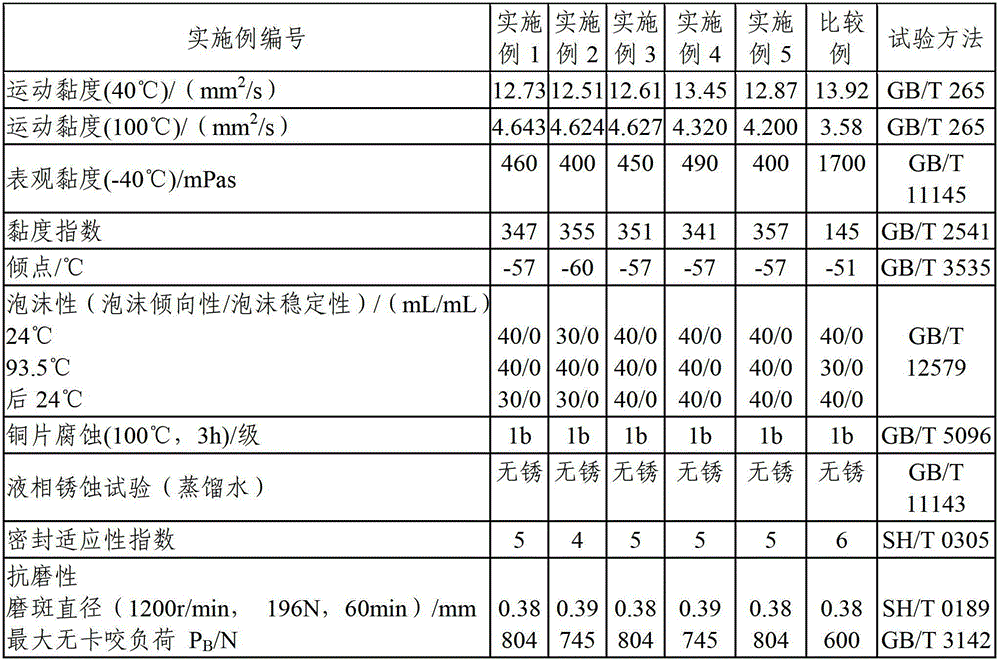

[0042] Use national or industry standard analytical methods to test the performance of the formula products in Examples 1-5, and compare them with the formula products in Example 3 of the patent CN 1343578A as a comparative example. The results are shown in Table 2.

[0043] The comparison of table 2 embodiment 1~5 product performance data and comparative example

[0044]

[0045] After analysis, the viscosity index of the shock absorber oil obtained in Examples 1-5 is about 350, and the low-temperature apparent viscosity is less than 500mPas, and the above two indicators are obviously better than those of the comparative example; in addition, the maximum non-jamming load is significantly greater than that of the comparative example , illustrating that the product of the present invention has better wear resistance than comparative examples. The analysis results show that the shock absorber oil of the present invention has extremely excellent viscosity-temperature performa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com