Perfluoropolyether grease for long-life high-temperature bearings and preparation method and application of perfluoropolyether grease

A perfluoropolyether, high-temperature bearing technology, used in lubricating compositions, petroleum industry, additives, etc., can solve the problems of inability to provide long-term lubrication protection, coking and carbon deposition, and excessive evaporation, and achieve excellent extreme pressure and wear resistance. and oxidation stability, low temperature conditions, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

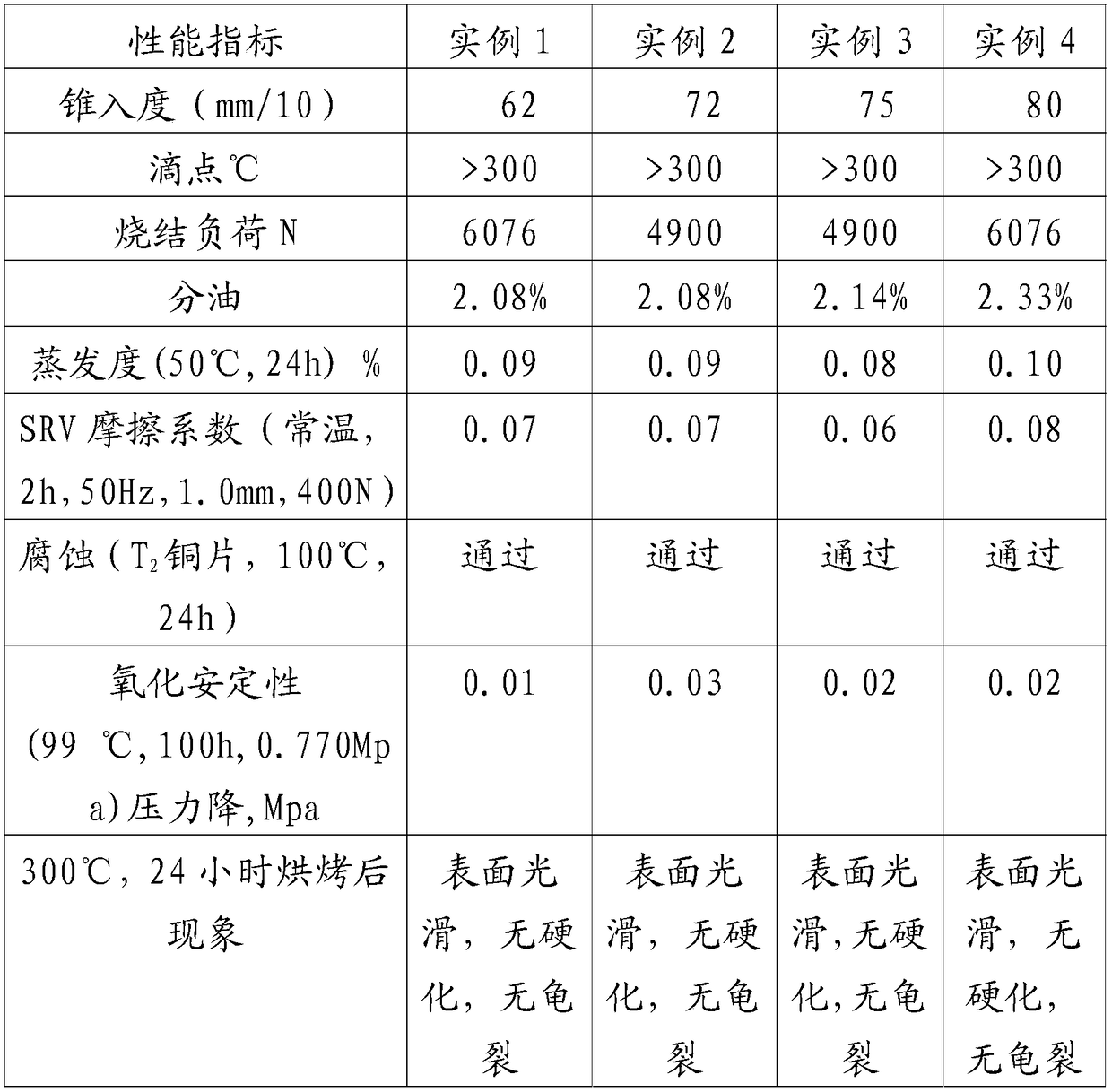

Examples

Embodiment 1

[0026] Take 5g molybdenum disulfide (commercially purchased from Pioneer Molybdenum Industry Co., Ltd. high-purity molybdenum disulfide) at 50°C and add it to 600g perfluoropolyether (available from Solvay perfluoropolyether lubricating oil M, molecular formula CF 3 -O-(CF 2 -CF 2 -O) m -(CF 2 -O) n -CF 3 , m=150, n=52), stirred for 1 h, and heated up to 60°C in a water bath ultrasonicator for 1 h. Add 400g of polytetrafluoroethylene thickener at 70°C, stir for 1 hour, and grind for 1 hour on a three-roll mill, then vacuum degass the grease after grinding, and then pack it.

Embodiment 2

[0028] Take 5g of petroleum sulfonate barium (commercially available from Jinzhou Shengda Chemical Co., Ltd. T701 petroleum sulfonate barium) at 60°C and add to 1.4kg of perfluoropolyether (available from Solvay perfluoropolyether lubricating oil M, molecular formula CF 3 -O-(CF 2 -CF 2 -O) m -(CF 2 -O) n -CF 3 , m=180, n=76), stirred for 1.5h, ultrasonicated in a water bath ultrasonicator at 60°C for 1.5h, then added 600g of calcium carbonate thickener at 60°C, stirred for 1h, and ground on a three-roll mill for 1.5h, then Carry out vacuum degassing post-treatment to the lubricating grease after grinding, and pack it.

Embodiment 3

[0030] Take 15g of molybdenum disulfide (commercially purchased from Pioneer Molybdenum Industry Co., Ltd. high-purity molybdenum disulfide) at 40°C and add it to 2.1kg of perfluoropolyether oil (available from Solvay perfluoropolyether lubricating oil M, molecular formula CF 3 -O-(CF 2 -CF 2 -O) m -(CF 2 -O) n -CF 3 , m=200, n=55), stirred for 2h, raised the temperature to 60°C and sonicated in a water bath ultrasonicator for 1.5h, then added 900g of bentonite thickener at 70°C, stirred for 1.5h, and ground on a three-roll mill for 2.5 h, and then carry out vacuum degassing post-treatment to the ground lubricating grease, and then pack it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com