Iron-based amorphous magnetically soft alloy and preparation method thereof

A soft magnetic alloy and iron-based amorphous technology, which is applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problems of weak amorphous formation ability and low soft magnetic performance, and improve the formation of amorphous The effect of high capacity, reasonable proportion and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

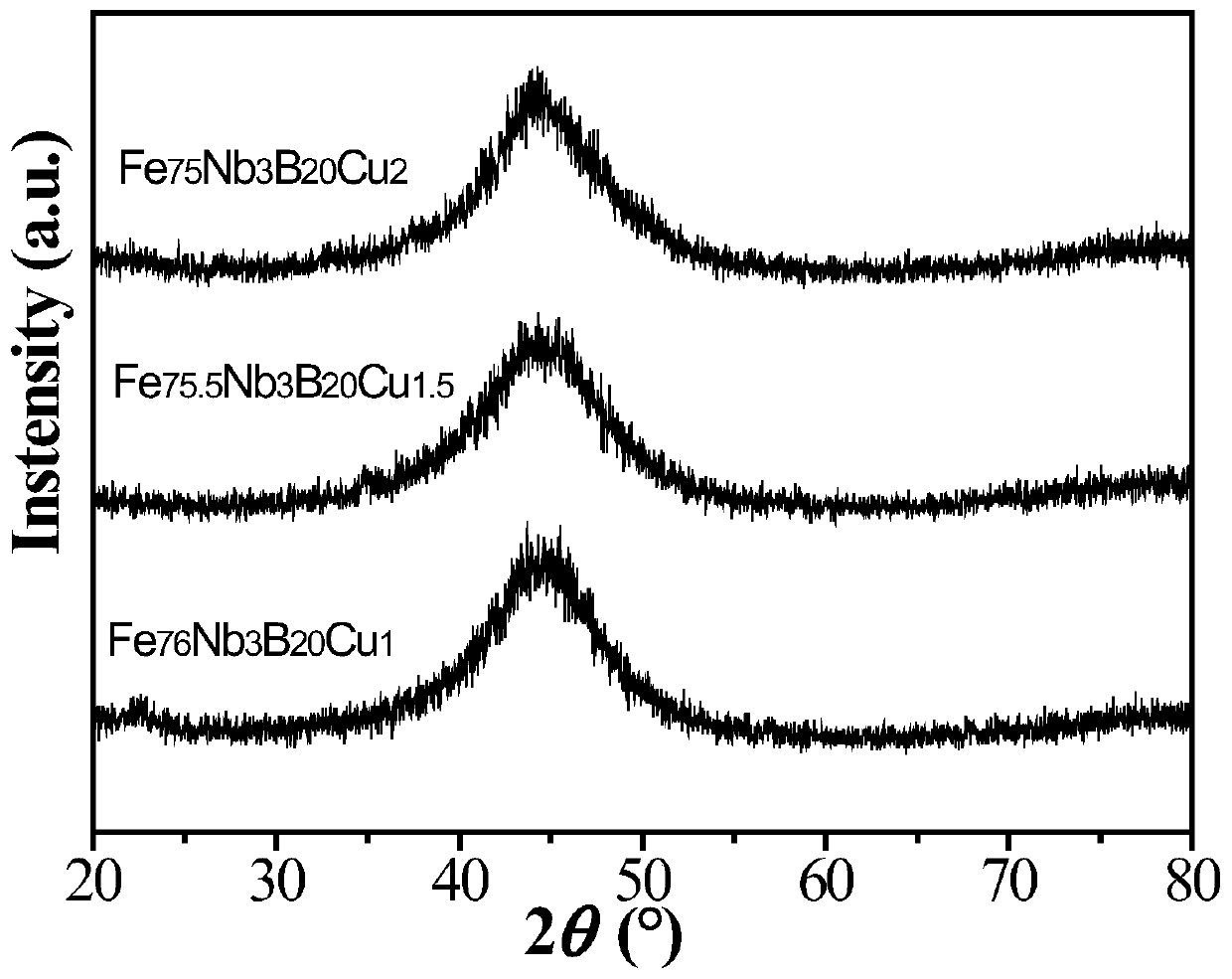

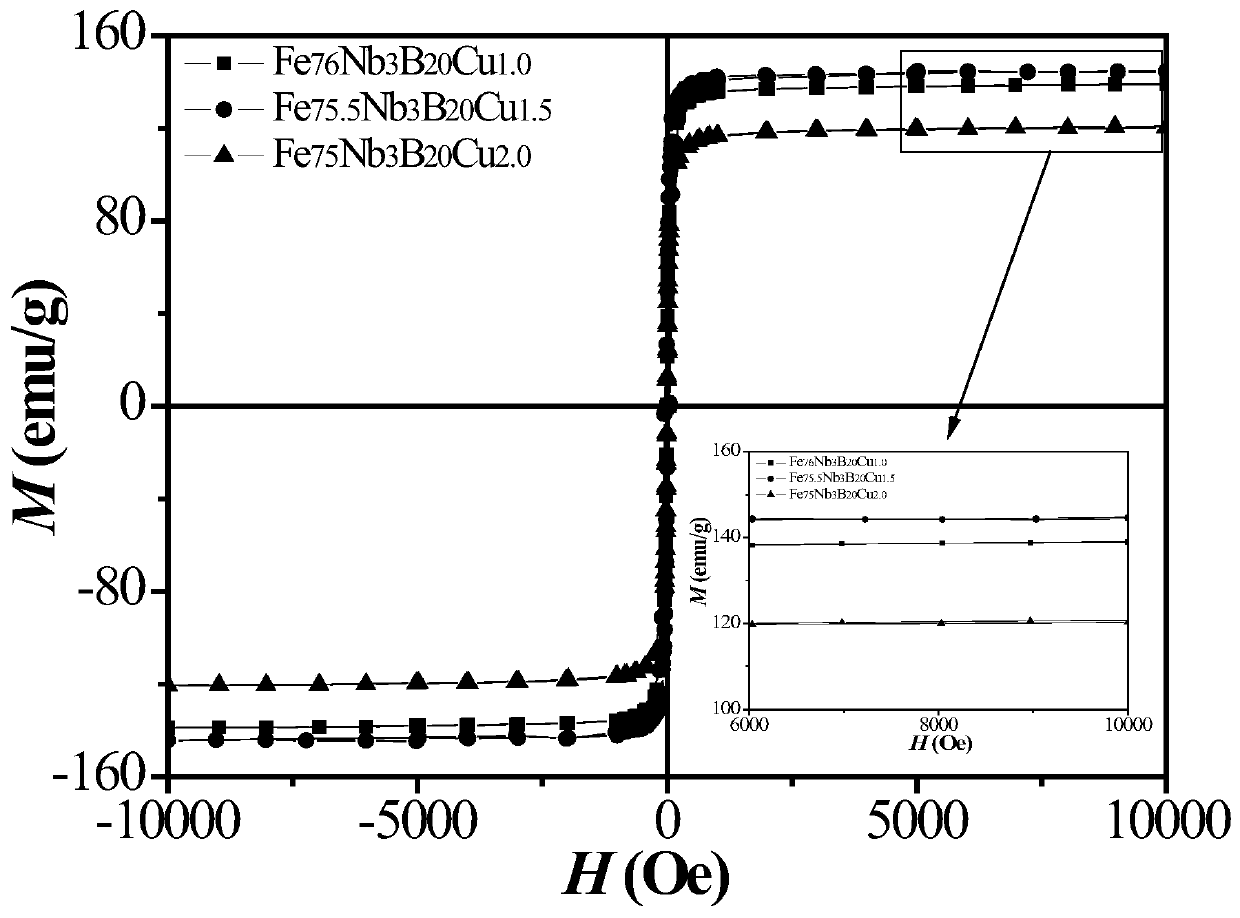

Embodiment 1

[0023] Embodiment 1: a kind of preparation method of iron-based amorphous soft magnetic alloy, comprises the following steps:

[0024] 1) batching: what the present embodiment prepared was Fe 76 Nb 3 B 20 Cu 1 Amorphous soft magnetic alloys, in terms of atomic percent Fe 76 Nb 3 B 20 Cu 1 Accurately weigh pure Fe, pure Cu and Fe-Nb, Fe-B master alloy;

[0025] 2) Smelting master alloy ingot: Put the target composition raw materials weighed after proportioning into the quartz tube and use B 2 o 3 The raw material is covered with glass, the high-frequency induction coil is used and the current is gradually increased from 5 A to 20 A, the induction heating is performed until the sample is completely melted, and the alloy composition is made to be uniform by repeated melting for 5 times, and Fe is obtained after cooling with the furnace. 76 Nb 3 B 20 Cu 1 Master alloy ingot; after that, use sandpaper to remove the oxide skin on the surface of the master alloy ingot, an...

Embodiment 2

[0028] Embodiment 2: a kind of preparation method of iron-based amorphous soft magnetic alloy, comprises the following steps:

[0029] 1) batching: what the present embodiment prepared was Fe 75.5 Nb 3 B 20 Cu 1.5 Amorphous soft magnetic alloys, in terms of atomic percent Fe 75.5 Nb 3 B 20 Cu 1.5 Accurately weigh pure Fe, pure Cu and Fe-Nb, Fe-B master alloy;

[0030] 2) Smelting master alloy ingot: Put the target composition raw materials weighed after proportioning into the quartz tube and use B 2 o 3 The raw material is covered with glass, the high-frequency induction coil is used and the current is gradually increased from 5 A to 20 A, the induction heating is performed until the sample is completely melted, and the alloy composition is made to be uniform by repeated melting for 5 times, and Fe is obtained after cooling with the furnace. 75.5 Nb 3 B 20 Cu 1.5 Master alloy ingot; after that, use sandpaper to remove the oxide skin on the surface of the master all...

Embodiment 3

[0033] Embodiment 3: a kind of preparation method of iron-based amorphous soft magnetic alloy, comprises the following steps:

[0034] 1) batching: what the present embodiment prepared was Fe 75 Nb 3 B 20 Cu 2 Amorphous soft magnetic alloys, in terms of atomic percent Fe 75 Nb 3 B 20 Cu 2 Accurately weigh pure Fe, pure Cu and Fe-Nb, Fe-B master alloy;

[0035] 2) Smelting master alloy ingot: Put the target composition raw materials weighed after proportioning into the quartz tube and use B 2 o 3 The raw material is covered with glass, the high-frequency induction coil is used and the current is gradually increased from 5 A to 20 A, and the induction heating is performed until the sample is completely melted, and the alloy composition is made to be uniform after repeated melting for 6 times, and Fe is obtained after cooling with the furnace. 75 Nb 3 B 20 Cu 2 Master alloy ingot; after that, use sandpaper to remove the oxide skin on the surface of the master alloy in...

PUM

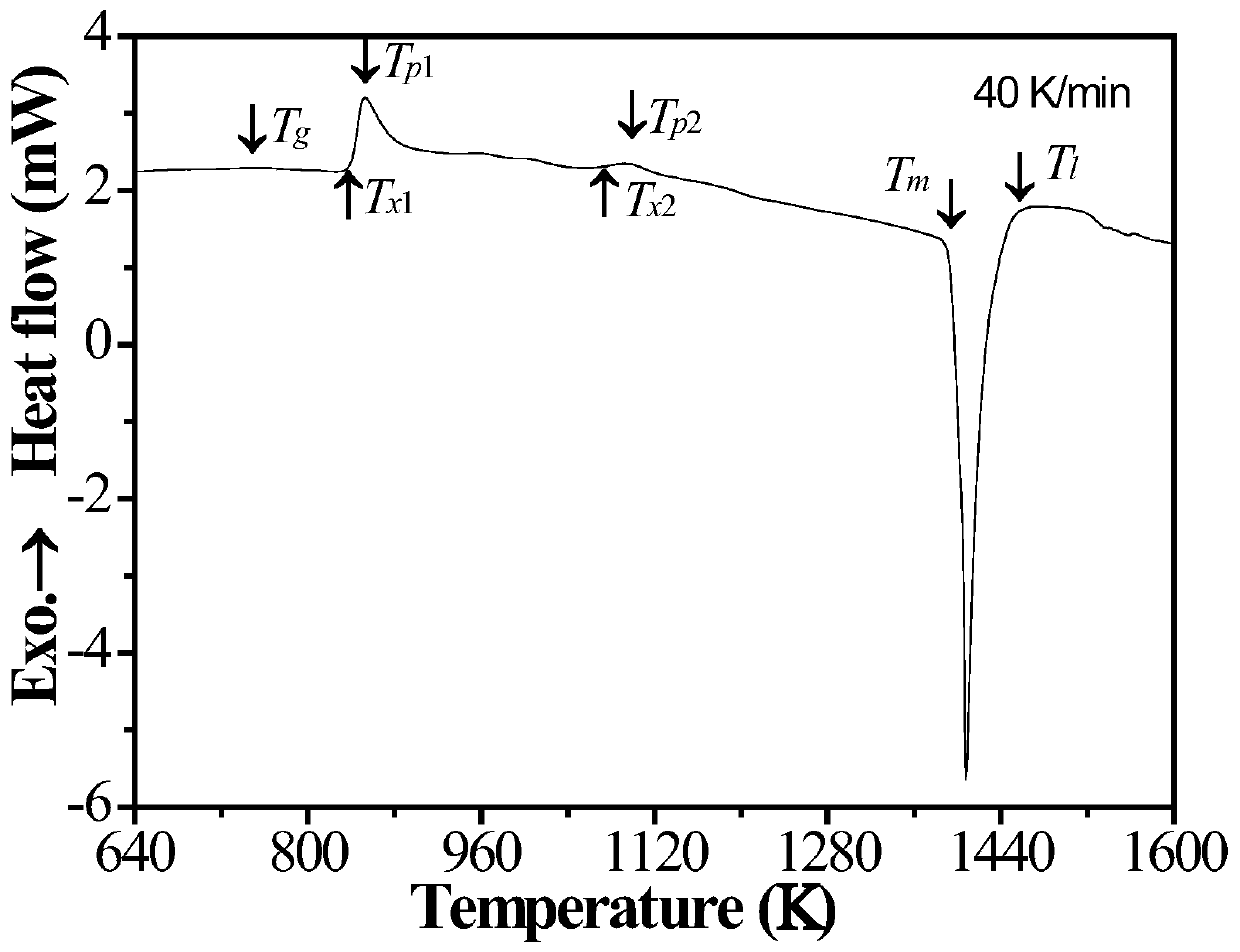

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Initial crystallization temperature | aaaaa | aaaaa |

| Saturation magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com