High-temperature overload transformer oil and preparation method thereof

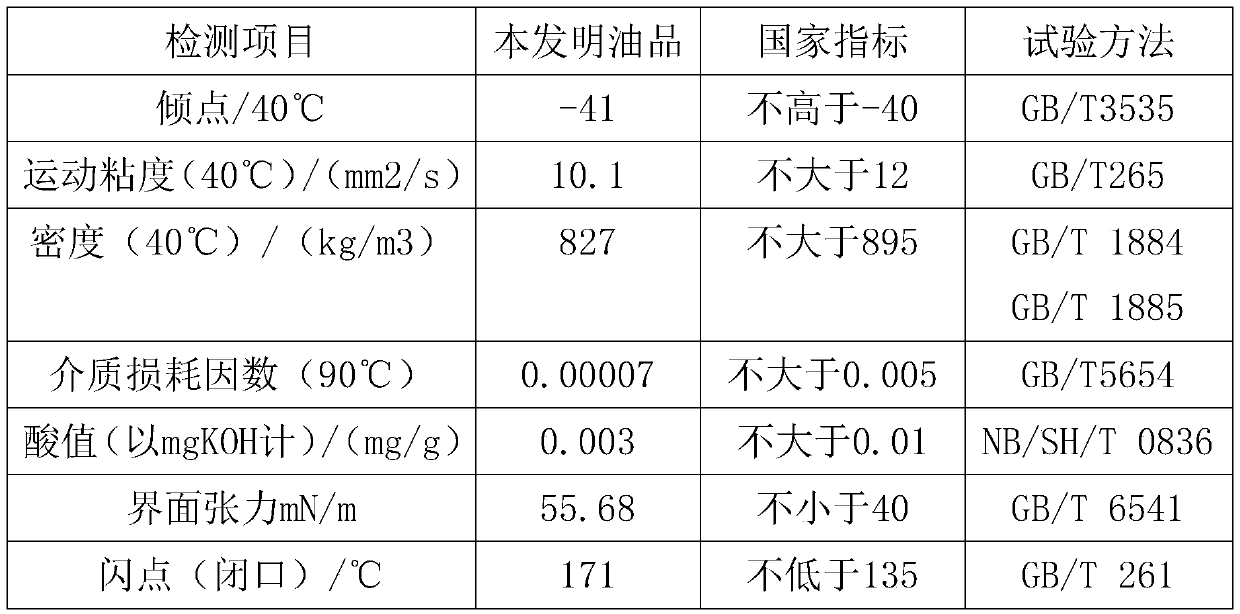

A transformer oil, high temperature technology, used in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of poor kinematic viscosity of transformer oil, poor anti-oxidative aging performance, and inability to obtain high flash point and good oil quality. , the effect of good gassing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Select 2kg of hydroxystearin, 2kg of dibutyl phosphophthalate, 3kg of sulfurized calcium alkylphenate, 2kg of methyl acrylate, 80kg of hydrogenated base oil, 1kg of kaolin, 2kg of 2,6-di-tert-butyl p-cresol, 2(2H-benzotriazol-2-yl)-6-dodecyl-4-methylphenol 2kg;

[0022] a. Choose a blending tank, put the base oil into the blending tank through the oil pump, start stirring, heat up to 40°C, then add clay and stir for 1 hour, then filter the raw materials twice through the diaphragm oil filter and the plate and frame oil filter ;

[0023] b. Add 2,6-di-tert-butyl-p-cresol and 2(2H-benzotriazol-2-yl)-6-dodecyl-4-methylphenol in the raw material according to the amount of raw material, Stir well;

[0024] c. After premixing the hydroxystearin, dibutyl phosphophthalate, sulfurized alkylphenate calcium and methyl acrylate in the raw materials, add them into the raw materials in step b, and stir evenly;

[0025] d. Refining and filtering the homogeneously mixed material in ...

Embodiment 2

[0027] Hydroxystearin 4kg, dibutyl phosphophthalate 4kg, sulfurized calcium alkylphenate 5kg, methyl acrylate 4kg, hydrogenated base oil 90kg, montmorillonite 3kg, 2,6-di-tert-butyl-p-cresol 4kg , 2(2H-benzotriazol-2-yl)-6-dodecyl-4-methylphenol 4kg;

[0028] a. Choose a blending tank, put the base oil into the blending tank through the oil pump, start stirring, heat up to 60°C, then add clay and stir for 1 hour, then filter the raw materials twice through the diaphragm oil filter and the plate and frame oil filter ;

[0029] b. Add 2,6-di-tert-butyl-p-cresol and 2(2H-benzotriazol-2-yl)-6-dodecyl-4-methylphenol in the raw material according to the amount of raw material, Stir well;

[0030] c. After premixing the hydroxystearin, dibutyl phosphophthalate, sulfurized alkylphenate calcium and methyl acrylate in the raw materials, add them into the raw materials in step b, and stir evenly;

[0031] d. Refining and filtering the homogeneously mixed material in the above step c t...

Embodiment 3

[0033] Hydroxystearin 3kg, dibutyl phosphophthalate 3kg, sulfurized calcium alkylphenate 4kg, methyl acrylate 3kg, hydrogenated base oil 85kg, diatomaceous earth 2kg, 2,6-di-tert-butyl-p-cresol 3kg , 2(2H-benzotriazol-2-yl)-6-dodecyl-4-methylphenol 3kg;

[0034] a. Choose a blending tank, put the base oil into the blending tank through the oil pump, start stirring, heat up to 50°C, then add white clay and stir for 1 hour, then filter the raw materials twice through the diaphragm oil filter and the plate and frame oil filter ;

[0035] b. Add 2,6-di-tert-butyl-p-cresol and 2(2H-benzotriazol-2-yl)-6-dodecyl-4-methylphenol in the raw material according to the amount of raw material, Stir well;

[0036] c. After premixing the hydroxystearin, dibutyl phosphophthalate, sulfurized alkylphenate calcium and methyl acrylate in the raw materials, add them into the raw materials in step b, and stir evenly;

[0037] d. Refining and filtering the homogeneously mixed material in the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com