Nitrogen-rich carbon sphere adsorbent for whole blood perfusion and preparation method thereof

An adsorbent and perfusion technology, which is applied in chemical instruments and methods, suction devices, and other chemical processes, can solve the problems of unsatisfactory removal effect, limited application value, platelet damage, etc., and achieve high safety and high mechanical strength , The effect of high blood compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Suspension polymerization

[0033] Stir 40g styrene, 60g divinylbenzene, 100g acrylonitrile, 160g toluene, 2g azobisisobutyronitrile to form an oil phase; mix 400g water and 2g hydroxypropyl methylcellulose and stir to obtain a water phase; Add the oil phase to the water phase, stir and suspend the reaction at 65°C for 12 hours to remove the porogen in the resin obtained by polymerization to obtain polymerized microspheres;

[0034] (2) Pre-oxidation

[0035] Pre-oxidize the polymeric microspheres obtained in step (1) by heating to 250°C for 2 hours in an air atmosphere to obtain pre-oxidized microspheres;

[0036] (3) Carbonization

[0037] The pre-oxidized microspheres obtained in step (2) are heated to 550°C at a rate of 10°C / min for 2h in a nitrogen atmosphere to obtain a nitrogen-rich carbon ball adsorbent for whole blood perfusion with a particle size of 0.3~1mm .

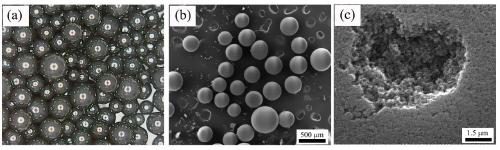

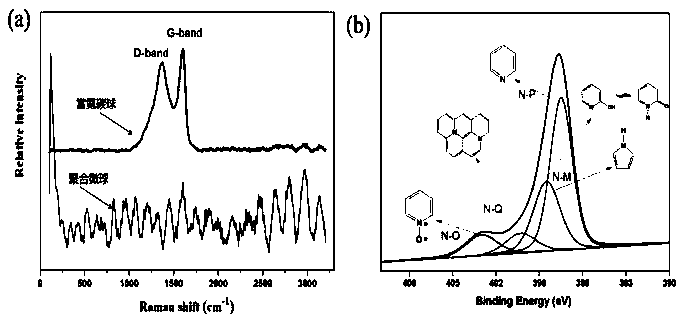

[0038] Attached figure 1 The optical microscope image and scanning electron microscope image of the nitr...

Embodiment 2

[0054] (1) Suspension polymerization

[0055] 50g methyl methacrylate, 50g divinylbenzene, 150g vinyl pyridine, 200g xylene, 3g azobisisoheptonitrile are stirred to form an oil phase; 800g water and 20g gelatin are mixed and stirred to obtain a water phase; The oil phase is added to the water phase, and the suspension is stirred for 5 hours at 70°C to remove the porogen in the resin obtained by polymerization to obtain polymerized microspheres;

[0056] (2) Pre-oxidation

[0057] The polymerized microspheres obtained in step (1) are heated to 230° C. for pre-oxidation for 2 hours in an air atmosphere to obtain pre-oxidized microspheres;

[0058] (3) Carbonization

[0059] Heat the pre-oxidized microspheres obtained in step (2) to 700°C at 8°C / min in an argon atmosphere, and heat-retain and carbonize for 1h to obtain a whole blood perfusion with a particle size of 1~2mm for adsorption by nitrogen-rich carbon balls Agent.

Embodiment 3

[0074] (1) Suspension polymerization

[0075] 30g methyl styrene, 70g 1,6-hexanediol diacrylate, 40g acrylonitrile, 10g vinyl pyridine, 100g ethyl acetate, 1g benzoyl peroxide are stirred to form an oil phase; 350g water and 3.5g Mix the hydroxyethyl cellulose and stir uniformly to obtain the water phase; add the oil phase to the water phase, stir and suspend the reaction at 68° C. for 8 hours to remove the porogen in the resin obtained by polymerization to obtain polymerized microspheres;

[0076] (2) Pre-oxidation

[0077] Pre-oxidize the polymeric microspheres obtained in step (1) by heating to 250°C for 2 hours in an air atmosphere to obtain pre-oxidized microspheres;

[0078] (3) Carbonization

[0079] The pre-oxidized microspheres obtained in step (2) were heated to 600°C at 5°C / min in an argon atmosphere, followed by thermal insulation and carbonization treatment for 3 hours to obtain nitrogen-rich carbon beads for whole blood perfusion with a particle size of 0.1~0.5mm Adsorbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com