Production process of high-strength high-toughness glass-fiber-reinforced septic tank

A glass tempering, high-strength and high-toughness technology, used in the field of sewage treatment, can solve the problems of easy corrosion, insufficient compression and bending resistance on the surface of storage tanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

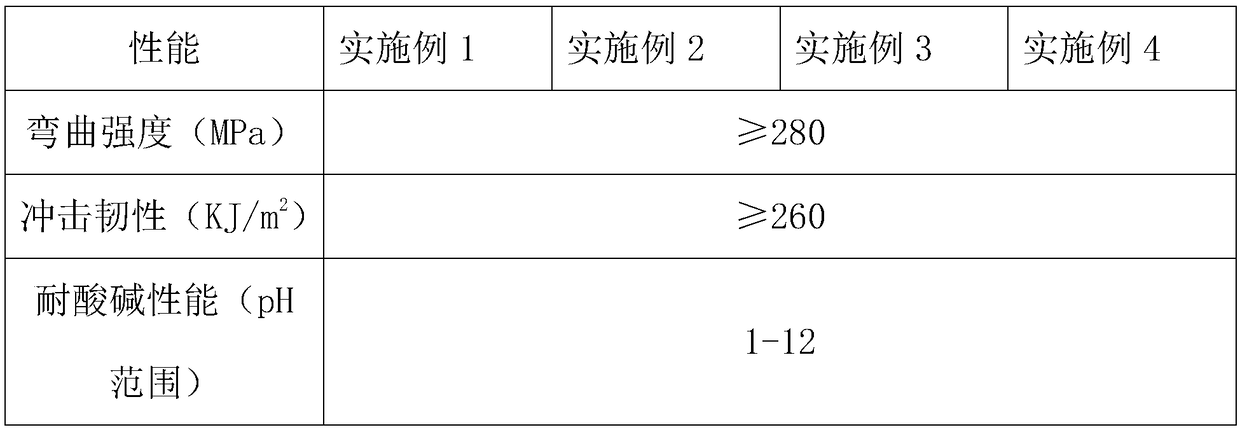

Examples

Embodiment 1

[0020] A production process for a high-strength and high-toughness fiberglass septic tank, comprising the following steps:

[0021] S1. Mix 5 parts of styrene and 0.5 parts of 2,6-di-tert-butyl-p-cresol by weight and add them to 30 parts of unsaturated polyester resin, then add 10 parts of novolac epoxy vinyl ester resin in turn , 0.2 parts of methyl ethyl ketone peroxide, 0.5 parts of calcium hydroxide, 1 part of polyoxyethylene castor oil, 2 parts of zinc stearate, stirred at a speed of 800r / min for 0.2h and then mixed, then added 25 parts of magnesium oxide, First stir at a high speed of 3500r / min for 0.1h, then stir at a low speed of 1000r / min for 0.3h and then mix to obtain a premix; the unsaturated polyester resin is bisphenol A type unsaturated polyester resin;

[0022] S2. Add 20 parts of reinforcing fibers to the premix obtained in S1, knead in a kneader for 0.6h, and then send it into an extruder to extrude at an extrusion temperature of 180°C, and pour it into a mo...

Embodiment 2

[0025] A production process for a high-strength and high-toughness fiberglass septic tank, comprising the following steps:

[0026] S1. Mix 10 parts of styrene and 0.2 parts of 2,6-di-tert-butyl-p-cresol by weight and add them to 40 parts of unsaturated polyester resin, then add 5 parts of isocyanate-modified acrylic vinyl Ester resin, 1 part of hydroxycumene peroxide, 0.1 part of calcium hydroxide, 3 parts of polyoxyethylene castor oil, 0.5 part of zinc stearate, stirred at a speed of 1000r / min for 0.1h and mixed well, then added 45 parts of magnesium oxide, first stirred at a high speed of 3000r / min for 0.2h, then stirred at a low speed of 800r / min for 0.5h and then mixed to obtain a premix; the unsaturated polyester resin was o-phthalic Unsaturated polyester resin;

[0027] S2. Add 40 parts of reinforcing fibers to the premixed material obtained in S1, knead in a kneader for 0.3h, and then send it into an extruder to extrude at an extrusion temperature of 220°C, and pour i...

Embodiment 3

[0030] A production process for a high-strength and high-toughness fiberglass septic tank, comprising the following steps:

[0031] S1. Mix 7 parts of styrene and 0.3 parts of 2,6-di-tert-butyl-p-cresol by weight and add them to 35 parts of unsaturated polyester resin, then add 7 parts of novolac epoxy vinyl ester resin in turn , 0.6 parts of benzoyl peroxide, 0.3 parts of calcium hydroxide, 2 parts of polyoxyethylene castor oil, 1.5 parts of zinc stearate, stirred at a speed of 900r / min for 0.15h and then mixed, then added 35 parts of magnesium oxide , first stir at a high speed of 3200r / min for 0.12h, then stir at a low speed of 900r / min for 0.4h and then mix to obtain a premix; the unsaturated polyester resin is an isophthalic unsaturated polyester resin;

[0032]S2. Add 30 parts of reinforcing fibers to the premixed material obtained in S1, knead in a kneader for 0.4h, and then send it into an extruder to extrude at an extrusion temperature of 200°C, and pour it into a mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com