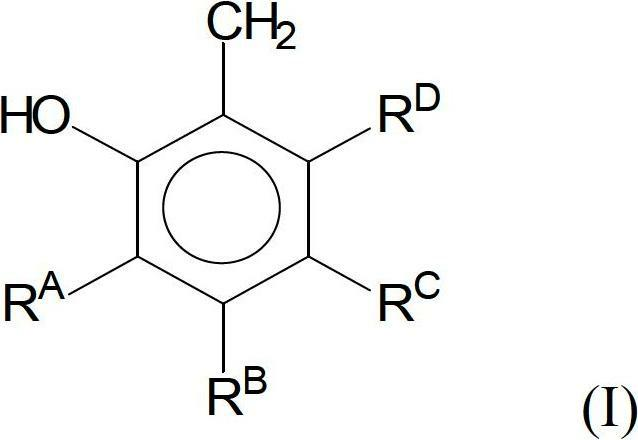

Method for stabilizing polyacrylate pressure-sensitive adhesives in admixture with adhesive resins

A pressure-sensitive adhesive, polyacrylate technology, applied in the direction of adhesives, adhesive types, acidic copolymer adhesives, etc., can solve the problems of tackifier resin oxidative damage, no implementation, browning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

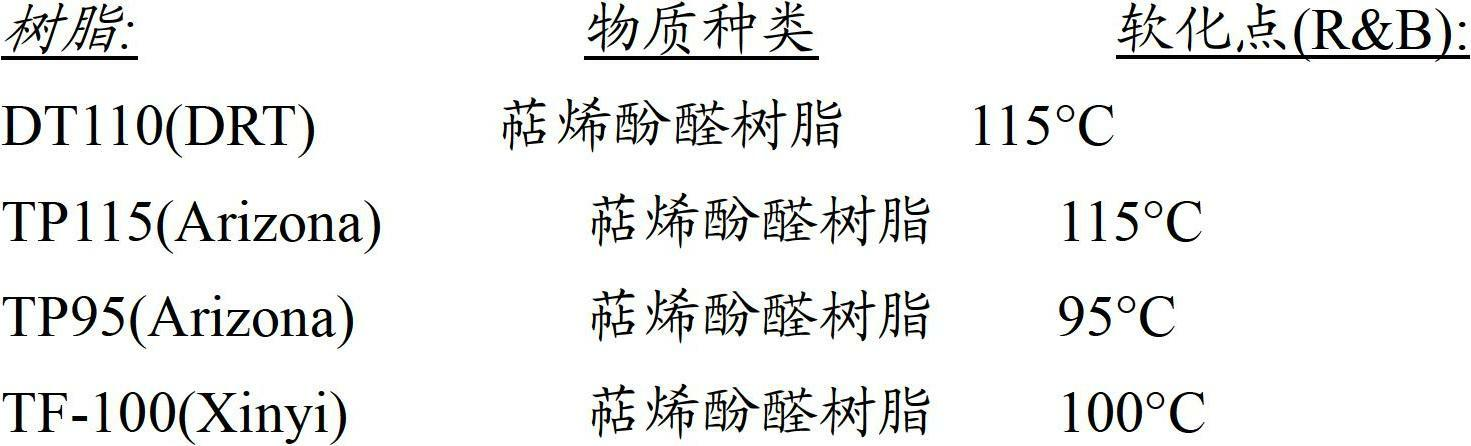

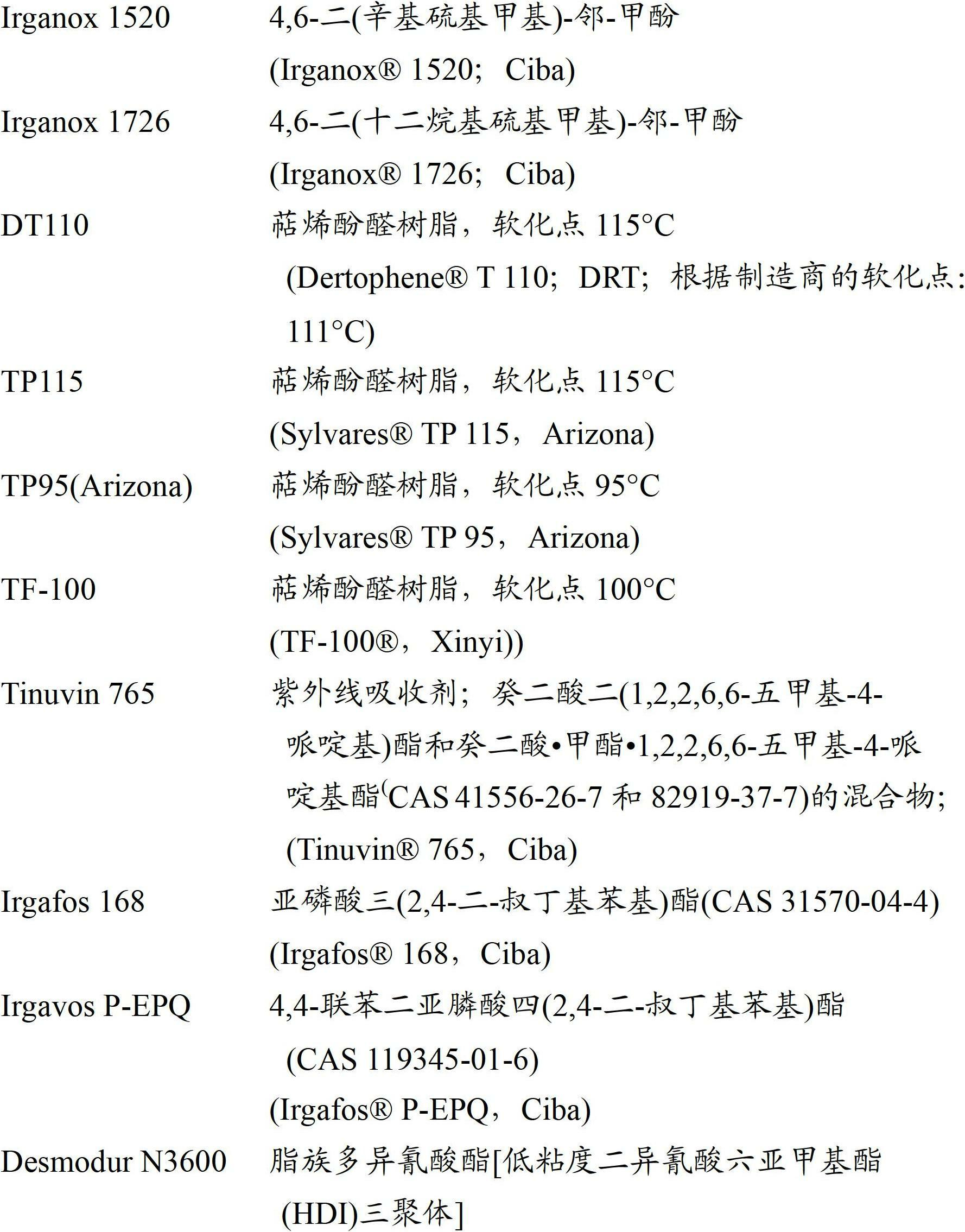

[0067] A polyacrylate PSA prepared by free radical polymerization in 60 / 95 benzine spirit based on 48.5 mol% acrylic acid was compounded with about 30% by weight of terpene phenolic resin TP95 from Arizona. The copolymer composition of 2-ethylhexyl ester, 48.5mol% butyl acrylate, 1mol% acrylic acid and 2mol% glycidyl methacrylate, weight average molecular weight (M w ) is about 1.5×10 6 g / mol. The compound was subsequently mixed with a 2% by weight solution of Irganox 1726 in 60 / 95 petrolatum. The mixture was then homogenized on a roller table for 24 hours.

[0068] The resulting resin-blended polyacrylate PSA was coated onto etched PET film at a coating weight of 50 g / m using a coating knife in a laboratory coating unit 2 .

[0069] The coated material was dried at room temperature for 24 hours and color measurements were taken as a reference.

[0070] The reference material was then heat-treated at 150°C for 3 hours in a forced-air drying oven.

[0071] The color and g...

Embodiment 2

[0082] A polyacrylate PSA prepared by free-radical polymerization in 60 / 95 petrolatum based on 48.5 mol% 2-ethyl acrylic acid was compounded with about 30 wt. The copolymer composition of hexyl hexyl ester, 48.5mol% butyl acrylate, 1mol% acrylic acid and 2mol% glycidyl methacrylate, weight average molecular weight (M w ) is about 1.5×10 6 g / mol. The compound was subsequently mixed with a mixture of 1% by weight of Irganox 1726 and 1% by weight of Irgafos 168 in 60 / 95 petrolatum. The mixture was then homogenized on a roller table for 24 hours.

[0083] The resulting resin-blended polyacrylate PSA was coated onto etched PET film at a coating weight of 50 g / m using a coating knife in a laboratory coating unit 2 .

[0084] The coated material was dried at room temperature for 24 hours and color measurements were taken as a reference.

[0085] The reference material was then heat-treated at 150°C for 3 hours in a forced-air drying oven.

[0086] The color and gloss of differe...

Embodiment 3

[0097] A polyacrylate PSA prepared by free-radical polymerization in 60 / 95 petrolatum was compounded with about 30% by weight of the terpene phenolic resin TP95 from Arizona and was composed of The copolymer composition of hexyl hexyl ester, 48.5mol% butyl acrylate, 1mol% acrylic acid and 2mol% glycidyl methacrylate, weight average molecular weight (M w ) is about 1.5×10 6 g / mol. The compound was then mixed with a mixture of 1% by weight of Irganox 1726 and 1% by weight of a solution of Tinuvin 765 in 60 / 95 petrolatum. The mixture was then homogenized on a roller table for 24 hours.

[0098]The resulting resin-blended polyacrylate PSA was coated onto etched PET film at a coating weight of 50 g / m using a coating knife in a laboratory coating unit 2 .

[0099] The coated material was dried at room temperature for 24 hours and color measurements were taken as a reference.

[0100] The reference material was then heat-treated at 150°C for 3 hours in a forced-air drying oven. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com