External thermal-insulation dry-mixed mortar of external wall

A technology for external thermal insulation of external walls and dry-mixed mortar, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc. High crack resistance, improved waterproof performance, and extended open time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

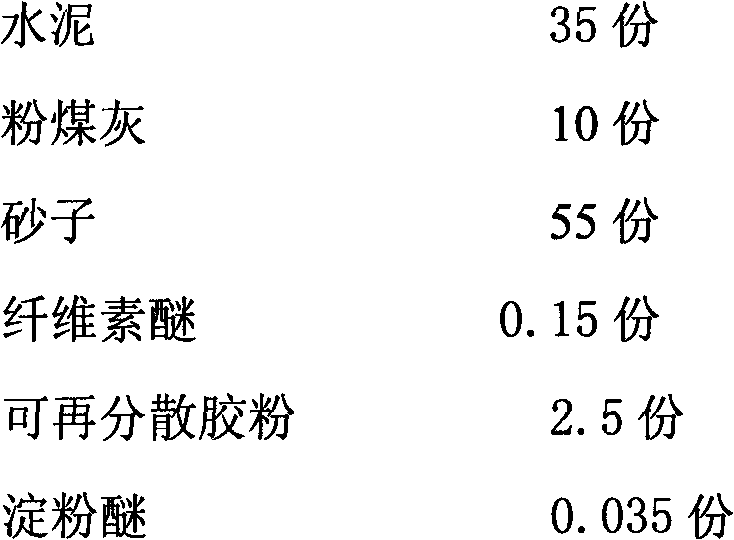

[0023] An external thermal insulation dry-mixed mortar is prepared from the following ingredients in proportions by weight:

[0024]

[0025] Its preparation process is to accurately measure each component according to the proportion, then add it to the mixing equipment in turn, stir evenly, and then it will be a finished product after being packed in bulk or in bags. When using it, add 21 parts of water and stir for 3-5 minutes. Stir evenly and the color is consistent. , which can be used for building construction.

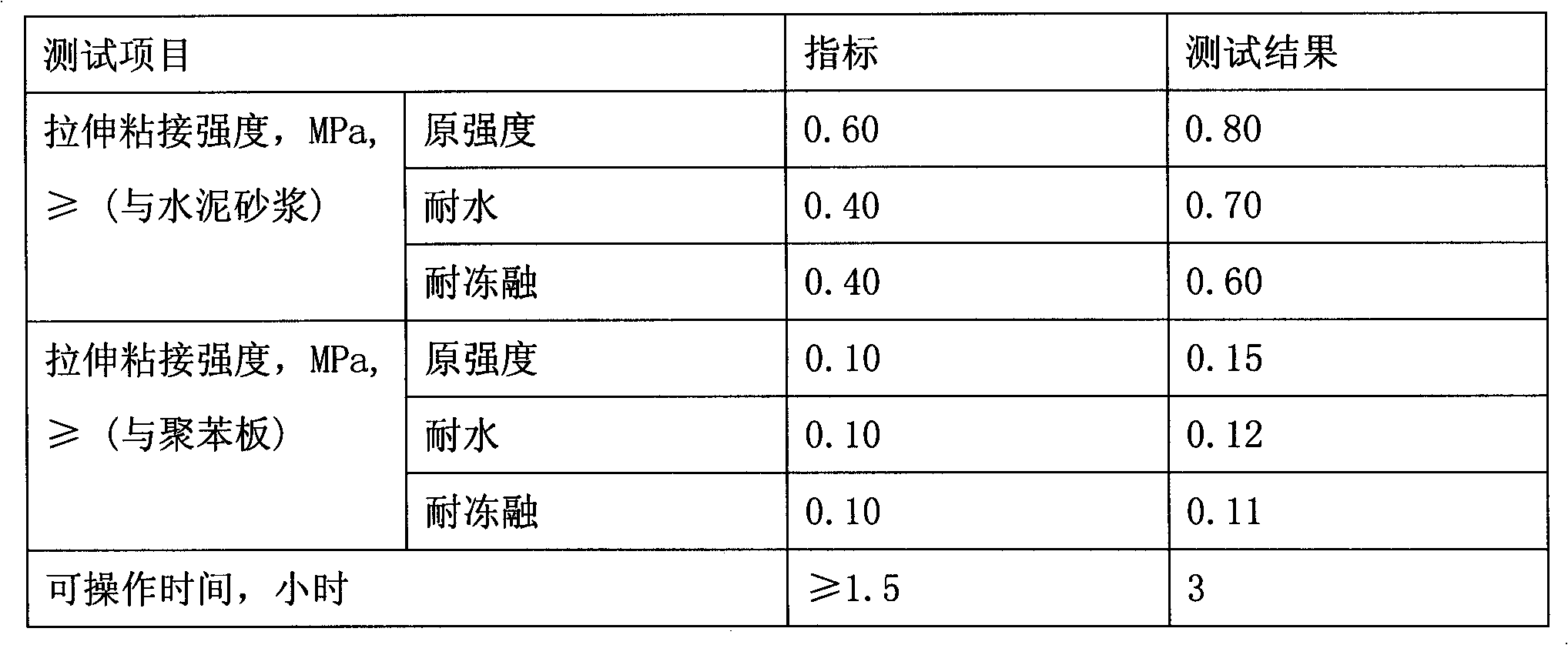

[0026]

Embodiment 2

[0028] An external thermal insulation dry-mixed mortar is prepared from the following ingredients in proportions by weight:

[0029]

[0030] Its preparation process is to accurately measure each component according to the proportion, then add them to the mixing equipment in turn, stir evenly, and then it will be the finished product after being packed in bulk or in bags. When using it, add 22 parts of water and stir for 3-5 minutes. Stir evenly and the color is consistent. , which can be used for building construction.

[0031]

Embodiment 3

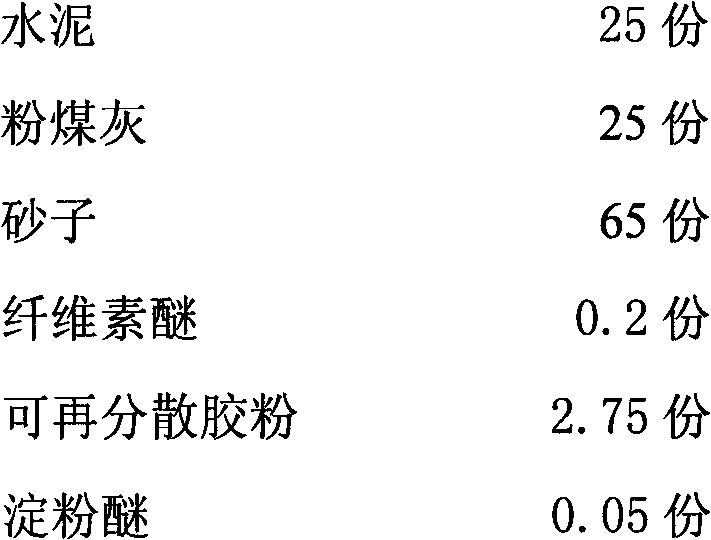

[0033] An external thermal insulation dry-mixed mortar is prepared from the following ingredients in proportions by weight:

[0034]

[0035] Its preparation process is to accurately measure each component according to the proportion, then add it to the mixing equipment in turn, stir evenly, and the finished product will be finished after bulk or bagged. When using, add 22.5 parts of water and stir for 3-5 minutes. Stir evenly and the color is consistent. , which can be used for building construction.

[0036]

[0037] In the above embodiments, the cement is ordinary Portland cement above grade 42.5. The fly ash is selected as Class C fly ash or Class F fly ash that conforms to the GB / T1596-2005 standard secondary product index. Sand is river sand with continuous gradation in the particle size range of 0.1-0.5mm. The cellulose ether is methyl hydroxyethyl cellulose ether (MHEC) or methyl hydroxypropyl cellulose ether (MHPC). The components of redispersible rubber powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com