Method for testing furosine in dairy products

A determination method and technology for dairy products, which are applied in the field of determination of furosine in dairy products, can solve the problems of large interference, high detection limit and low recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

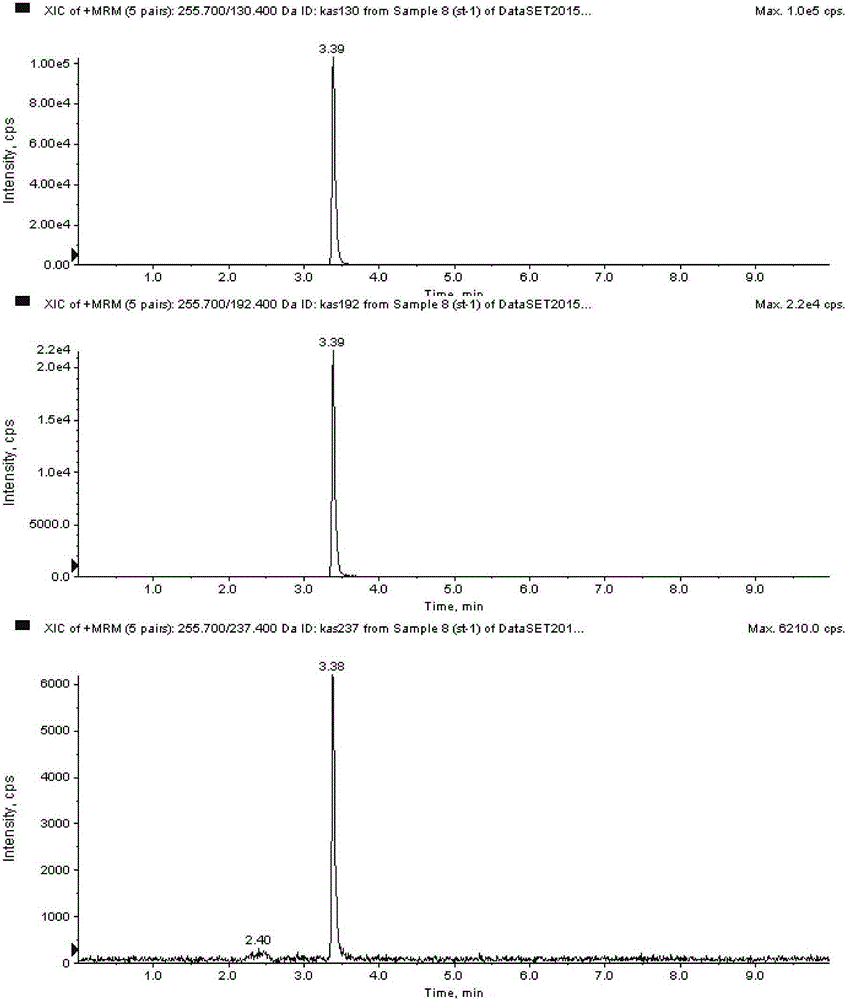

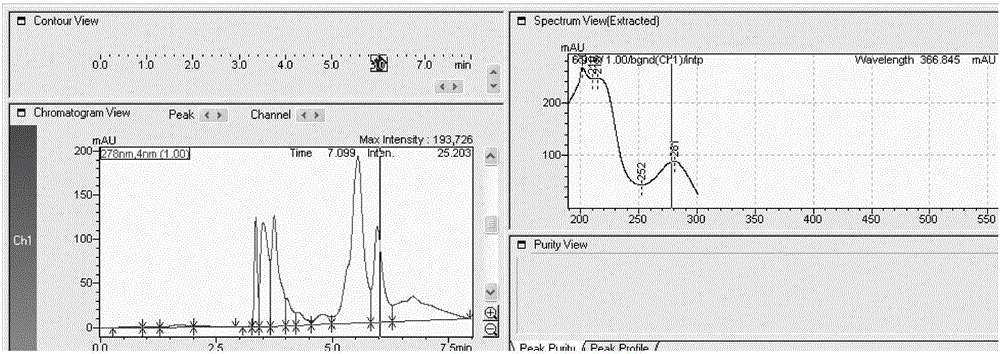

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: a preferred embodiment of detection method of the present invention

[0050] Four samples of raw milk, reconstituted milk, pasteurized milk and ultra-high temperature (UHT) instant sterilized milk were selected for testing. Among them, raw milk is regular milk from healthy dairy animals, which has only been cooled and possibly filtered, but has not been pasteurized, heat treated below pasteurization, cleaned milk or other sterilization treatments; reconstituted milk is condensed milk or X Raw milk blended with whole milk powder and water; pasteurized milk is kept at low temperature for a long time (62°C to 65°C for 30 minutes) or at high temperature for a short time (72°C to 76°C for 15s; or 80°C ℃~85℃, kept for 10~15s); ultra-high temperature (UHT) instant sterilized milk is processed by keeping above 135℃ for several seconds.

[0051] (1) Sample preparation

[0052]Take 2.00mL sample with a pipette gun, put it in a heat-resistant test tube with a seal,...

Embodiment 2

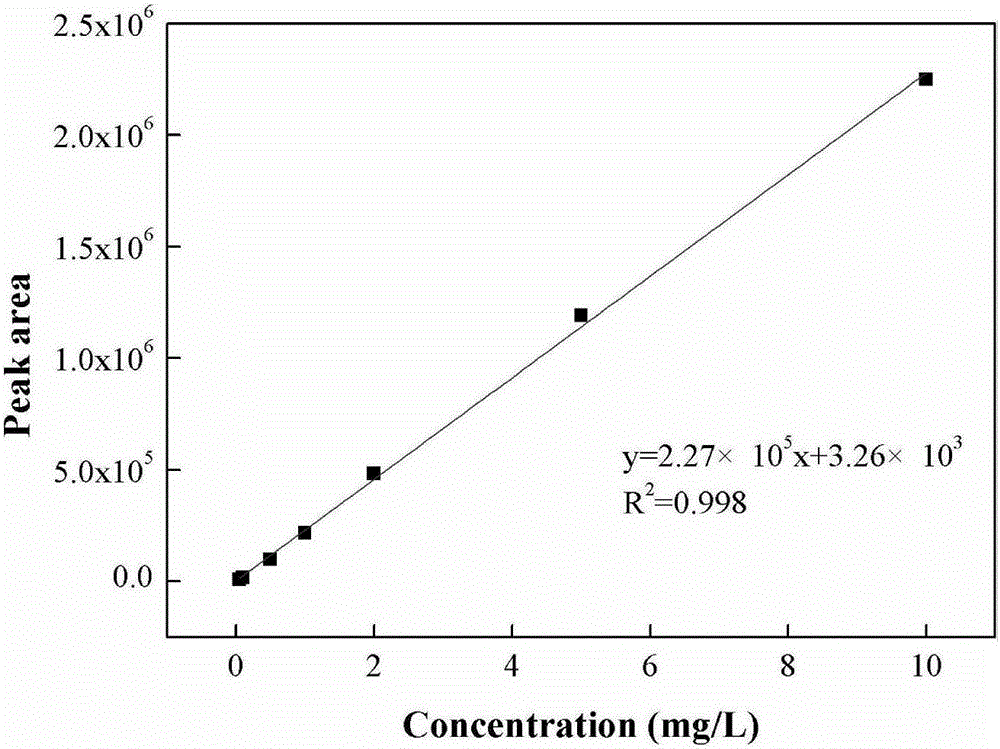

[0107] Embodiment 2: Determination of the lower limit of determination

[0108] In the experiment, 3 times the standard deviation of the blank measurement was used as the lower limit of determination, and 10 times the standard deviation was used as the quantitative detection limit. Three parallel measurements were taken to obtain the average value, and the detection limit LOD of the established HPLC method was obtained.

[0109] According to the experimental results, the lower limit of determination of furosine is 0.01 mg / kg, and the quantitative detection limit is 0.04 mg / kg.

Embodiment 3

[0110] Embodiment 3: the mensuration of recovery rate

[0111] Accurately measure two test samples with known fururine content (2.2mg / kg and 2.7mg / kg), and then add a certain amount of standard samples (0.5mg / kg, 1.0mg / kg, 2.0mg / kg ), calculate the standard addition recovery rate according to the above method, the results are shown in Table 3, and Table 3 is the recovery rate of the furosine assay method.

[0112] From the experimental results, the recovery rate of furosine in milk powder ranges from 93.4% to 108.9%.

[0113] table 3

[0114]

[0115]

PUM

| Property | Measurement | Unit |

|---|---|---|

| correlation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com