Liquid milk and preparation method thereof

A technology of liquid milk and fresh milk, applied in dairy products, milk preparations, applications, etc., can solve problems such as reducing taste, destroying nutritional components, and poor sterilization effect, and achieves the effect of high nutritional value and intact nutritional components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

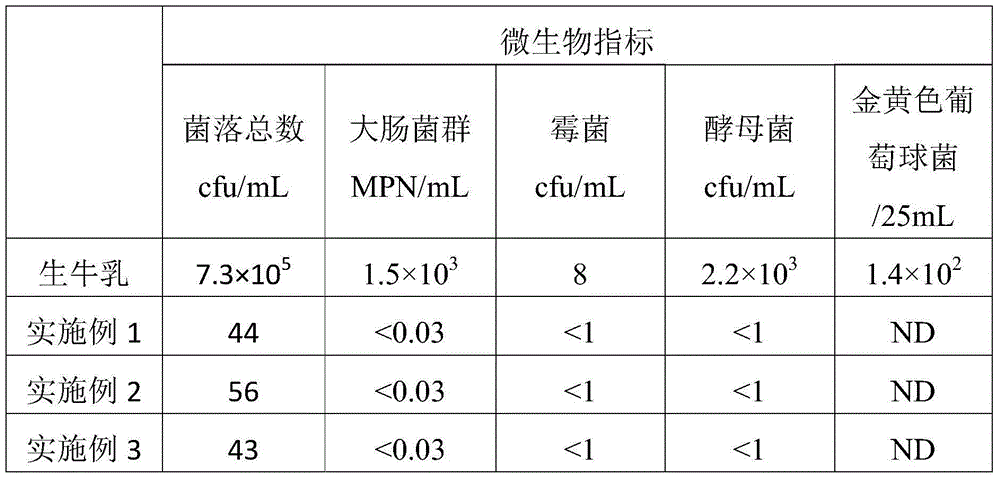

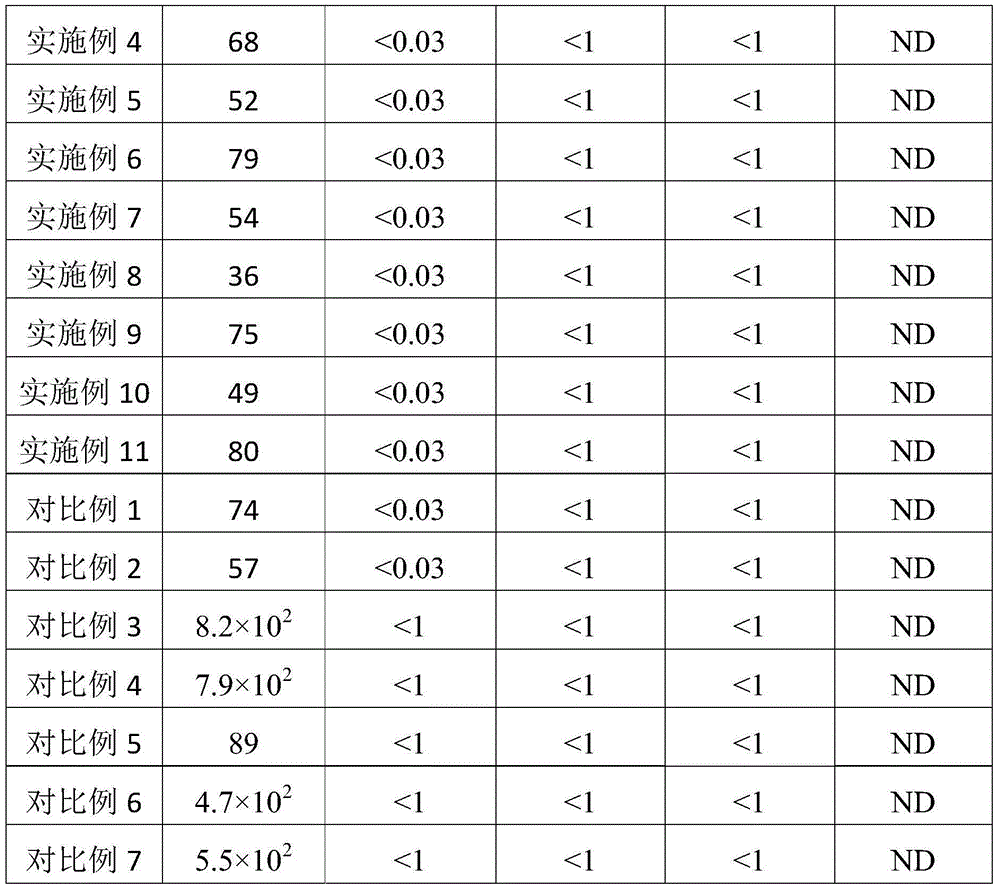

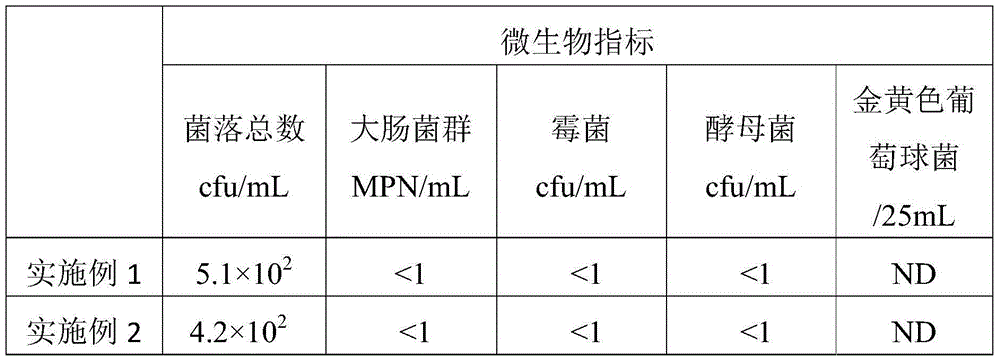

Examples

Embodiment 1

[0018] (1) Centrifuge 5 tons of raw milk to clean milk, the centrifugal speed is 6000rpm, and the processing speed is 20t / h. After cleaning, the raw milk is pre-sterilized at 63°C for 15s. After sterilization, the milk is cooled to 4°C for use.

[0019] (2) The pre-sterilized raw milk is standardized and homogenized. The homogenization temperature is 60°C and the homogenization pressure is 180 bar. The pre-sterilized raw milk is standardized. The standardized index is: fat 3.1 %, protein 2.9%, said percentage is the mass percentage accounting for the total mass of milk after said standardization;

[0020] (3) Cool the raw milk homogenized in step (2) to 4°C, and fill it in a clean environment with Tetra Pak;

[0021] (4) Put the raw milk filled in step (3) into the ultra-high pressure equipment, the sterilization pressure is 200MPa, and the time is 5min;

[0022] (5) Treat the raw milk processed in (4) with ultra-high pressure for the second time, the pressure is 600MPa, and ...

Embodiment 2

[0025](1) Centrifuge 5 tons of raw milk to clean the milk, the centrifugal speed is 5000rpm, and the processing speed is 25t / h; the raw milk after the cleaning is 65°C, 20s pre-sterilization treatment; the sterilized milk is cooled to 4°C for use;

[0026] (2) The pre-sterilized raw milk is homogenized after standardization. The homogenization temperature is 65° C. and the homogenization pressure is 220 bar. The standardized indicators of the pre-sterilized raw milk are: fat 3.3%, protein 3.1%, the percentage is the mass percentage of the total mass of the standardized raw milk;

[0027] (3) Cool the raw milk homogenized in step (2) to 4°C, choose Ecolean packaging, and fill it in a clean environment;

[0028] (4) Put the raw milk filled in step (3) into the ultra-high pressure equipment, the sterilization pressure is 300MPa, and the time is 2min;

[0029] (5) Treat the raw milk processed in (4) with ultra-high pressure for the second time, the pressure is 600MPa, and the tim...

Embodiment 3

[0032] (1) Centrifuge 5t of raw milk to clean milk, the centrifugal speed is 5000rpm, and the processing speed is 23t / h; the raw milk after cleaning is standardized and then homogenized. The homogenization temperature is 65°C and the homogenization pressure is 200bar The standardized index of the raw milk after cleansing is: 3.2% fat, 3.4% protein, and the percentage is the mass percentage of the total mass of the standardized raw milk;

[0033] (2) Cool the homogenized raw milk in step (1) to 4°C, and fill it in a small-diameter PET bottle in a clean environment;

[0034] (3) Put the raw milk filled in step (2) into the ultra-high pressure equipment, the sterilization pressure is 200MPa, and the time is 5min;

[0035] (4) Treat the raw milk processed in (3) with ultra-high pressure for the second time, the pressure is 500MPa, and the time is 20min;

[0036] (5) After the sterilization is completed, take it out to obtain sterilized milk, clean the surface, and store it in a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com