Hot water pasteurization device of fresh milk and automatic control method thereof

A pasteurization and hot water technology, applied in the field of fresh milk processing, can solve the problems of large loss of milk nutrition, disappearance of milk flavor, long sterilization time, etc. effect of taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

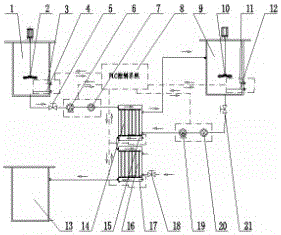

[0041] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

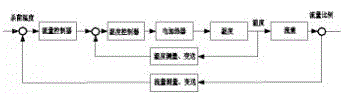

[0042] like figure 1 As shown, the implementation of the automatic control method of the present invention is that the raw milk is heated by the raw milk electric heater 4 and stirred by the raw milk agitator 2 in the raw milk tank 1 to reach the preset temperature T1, and then the raw milk is passed through the raw milk metering pump 6 and Raw milk flow transmitter 7 controls the fresh milk flow F determined by formula (4) M1 , pass through the sterilizer 14 within 15 seconds; the hot water in the hot water tank 9 is heated by the hot water electric heater 12 and stirred by the hot water agitator 10 to reach the preset temperature T2, and the hot water metering pump 19 and the hot water flow change Conveyor 20 is controlled by PLC control system 8 to determine the hot water flow rate F determined by formula (1) and formula (2) M2 , through the hot water fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com