Liquid milk preparation method

A technology of liquid milk and emulsion, which is applied in the direction of dairy products and milk preservation and application, can solve the problems of undiscovered liquid milk processing methods and equipment, etc., and achieve the effects of avoiding thermal sterilization process, prolonging shelf life and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

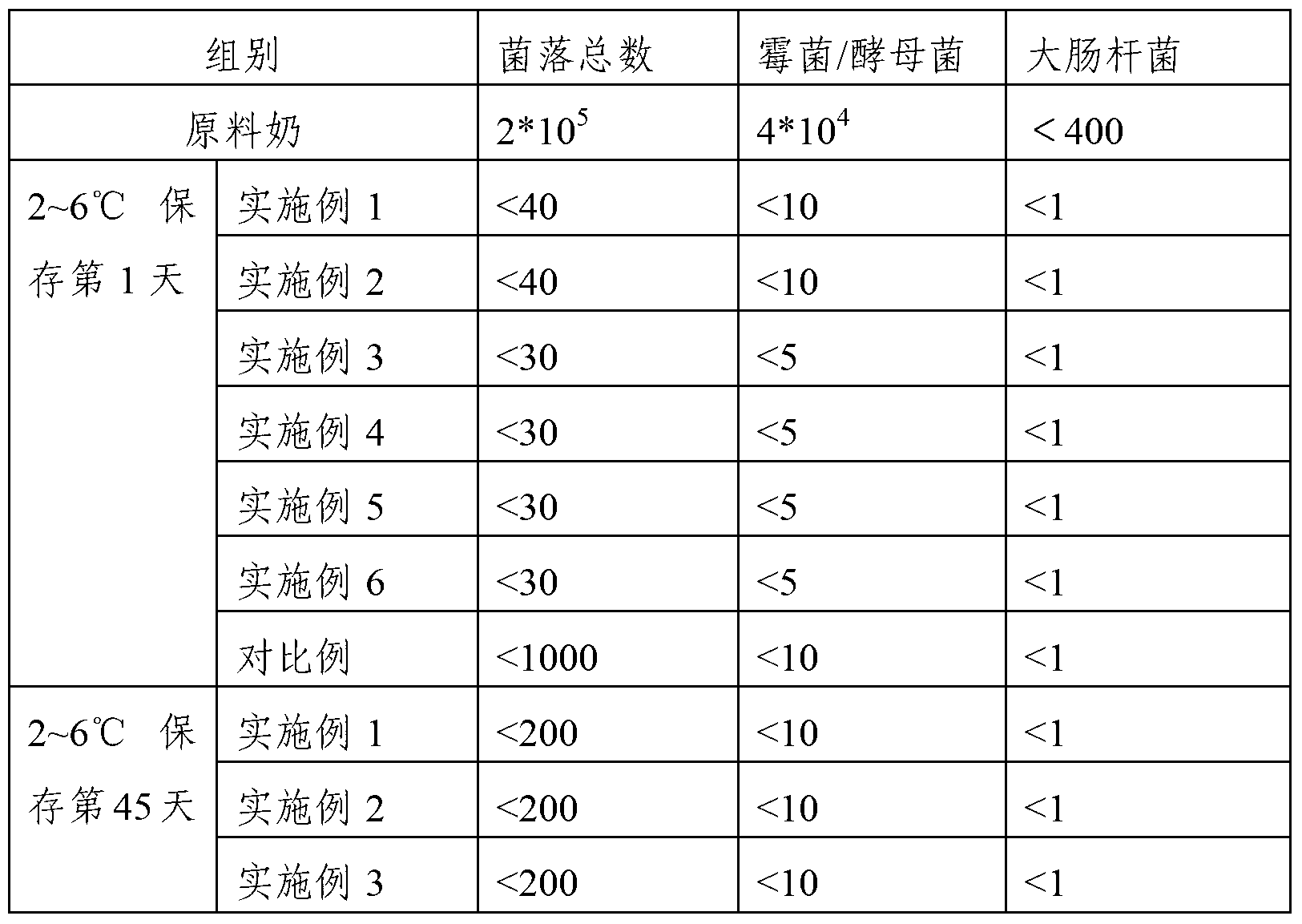

Embodiment 1

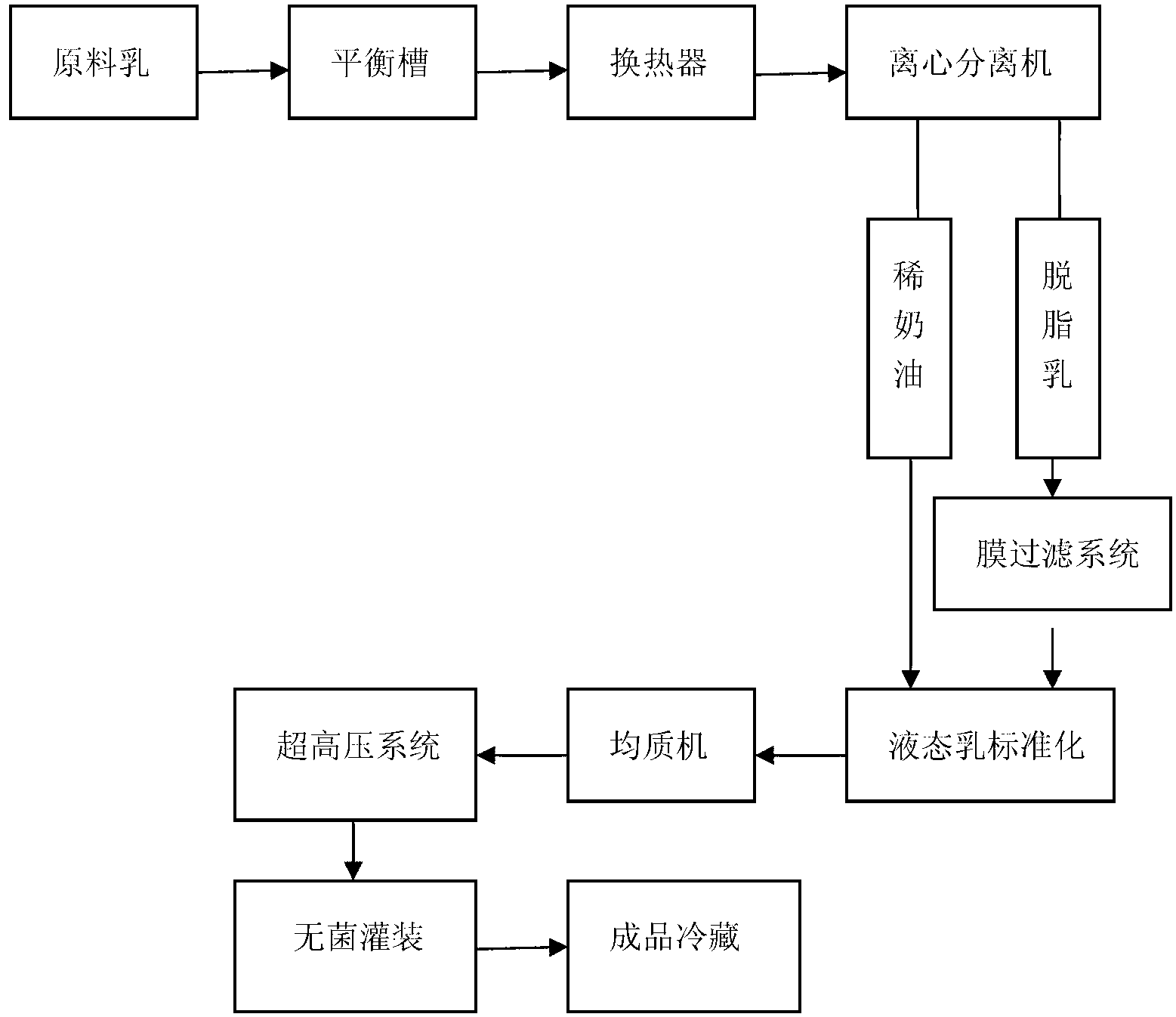

[0031] see figure 1 . After cleaning the qualified raw milk, the temperature is raised to 50°C, and centrifuged to obtain skim milk and cream. The obtained skim milk enters the ceramic membrane (membrane pore size 0.45μm) filtration system at 50°C for microfiltration primary sterilization, and the obtained cream is standardized and mixed with the skim milk after primary sterilization, that is, the mixed full-fat liquid The fat content in the milk is 3.3% (mass ratio). The standardized full-fat liquid milk is homogenized under the conditions of 60°C and 200Bar (Swedish Tetra Pak Homogenizer). The homogenized liquid milk passes through the heat exchange equipment and the temperature drops to 20°C, transfer to a container (balance tank), ready for ultra-high pressure sterilization.

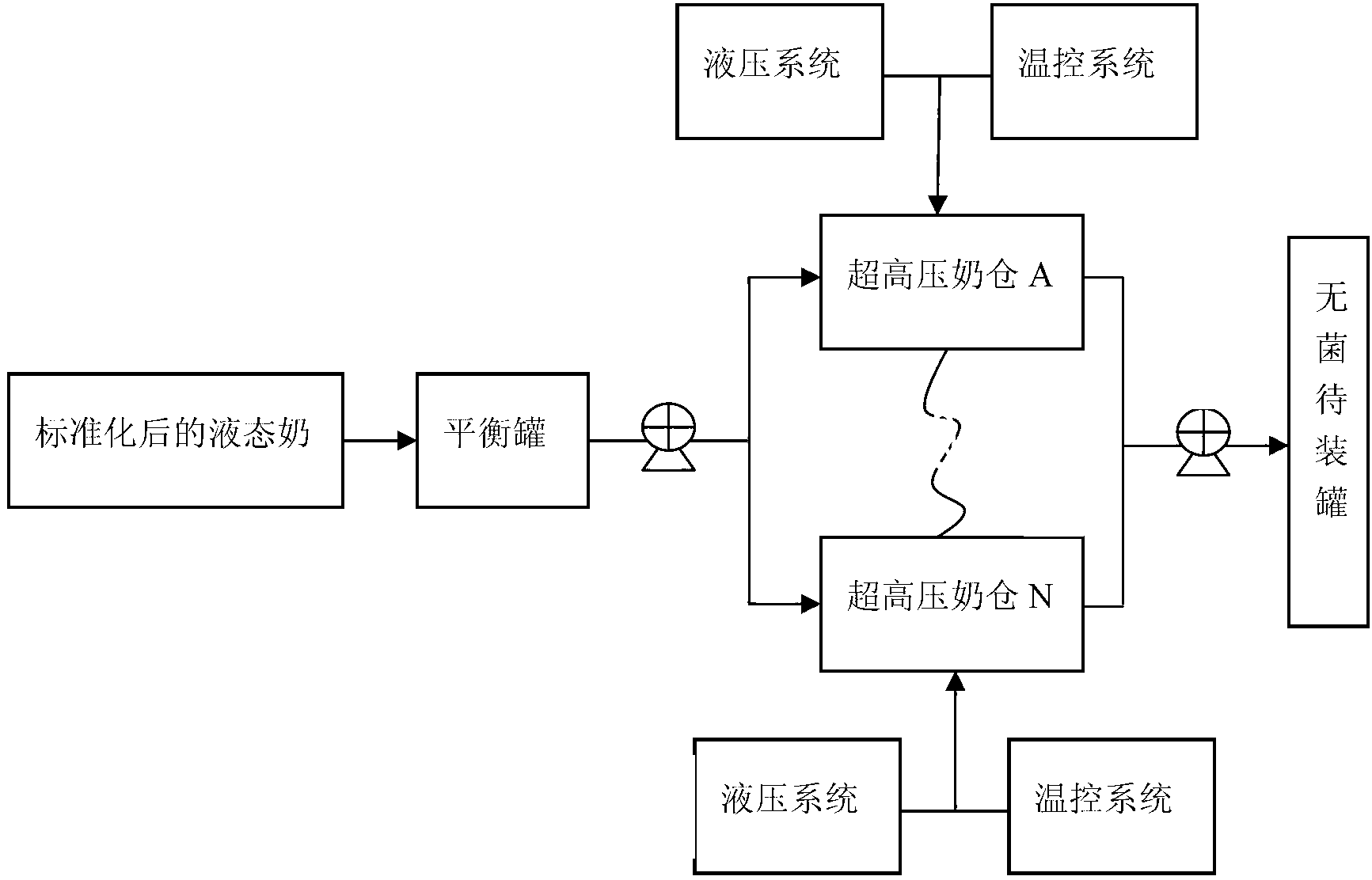

[0032] Ultra-high pressure sterilization equipment ( figure 2 ) is a horizontal high static pressure sterilization equipment. Its ultra-high pressure sterilization workflow is as follows: the fir...

Embodiment 2

[0035] After cleaning the qualified raw milk, the temperature is raised to 55°C, and centrifuged to obtain skim milk and cream. The obtained skim milk enters the ceramic membrane filtration system at 55°C for microfiltration primary sterilization, and the obtained skim milk and cream are standardized and mixed to a fat content of 3.0% (mass ratio), and the standardized whole liquid milk is heated at 60°C , Homogenized under the condition of 200Bar, the liquid milk after homogenization passes through the heat exchange equipment, the temperature drops to 20 ℃, and is transferred to the container (balance tank), ready for ultra-high pressure sterilization.

[0036] The liquid milk is injected into the ultra-high pressure sterilization equipment, passes through 550MPa at room temperature of 20°C, is discharged from one end of the high-pressure chamber after 12 minutes, and then is aseptically filled. Store at 4°C.

Embodiment 3

[0038] The accepted liquid milk is cleaned and warmed up to 50°C, and centrifuged to obtain skim milk and cream. The obtained skim milk enters the ceramic membrane filtration system at 50°C for microfiltration primary sterilization, and the obtained cream is standardized with the skim milk after primary sterilization until the fat content is 1.6% (mass ratio), and the standardized part Skim liquid milk is homogenized at 58°C and 180Bar. The homogenized liquid milk passes through heat exchange equipment, the temperature drops to 8°C, and is transferred to a container (balance tank) for one day.

[0039] The liquid milk in the balance tank is injected into the ultra-high pressure sterilization equipment, passes through 500MPa at 15°C, and is discharged from one end of the high-pressure chamber after 15 minutes for aseptic filling. Store at 4°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com