Ice cream and preparation method thereof

A technology for ice cream and dairy products, applied in frozen desserts, food science, applications, etc., can solve problems such as ice cream to be developed, and achieve the effects of excellent flavor, good flavor and high nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] In this example, ice cream was prepared as follows:

[0061] Ice cream formula: raw milk: 565kg, white sugar: 140kg, skimmed milk powder: 70kg, cream: 200kg, coconut oil: 20kg, locust bean gum: 1.2kg, xanthan gum: 0.6kg, sodium carboxymethylcellulose: 0.6 kg, glyceryl monostearate: 1.2kg, vanilla essence: 1.0kg.

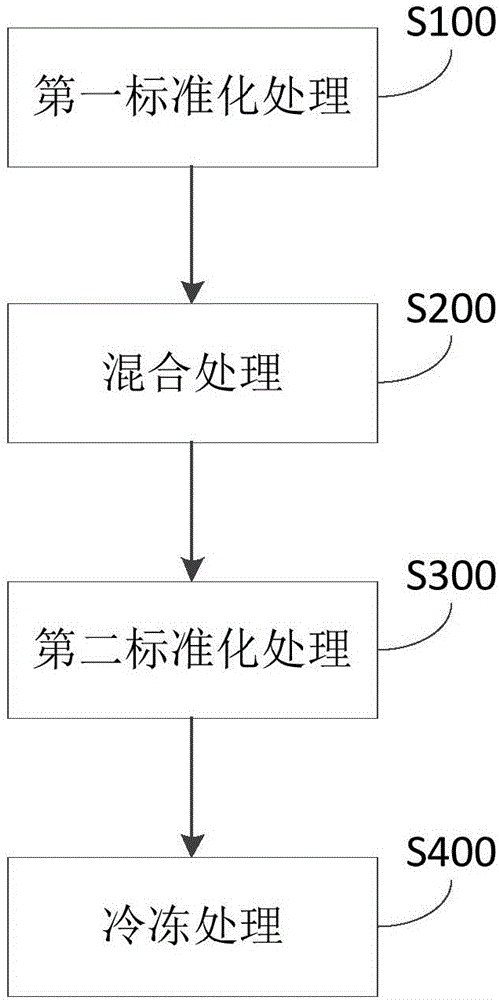

[0062] Raw milk standardization→mixing→raw material standardization→sterilization→homogenization→cooling→aging→freezing→filling→quick freezing→packaging→storage

[0063] For the raw milk test, the raw milk was standardized for the first time according to the test results. After the standardization, the solid content in the raw milk was 11.6%.

[0064] All the raw materials (removing essence) are mixed evenly, and inspected, and the ice cream feed liquid is standardized for the second time according to the inspection result, and the solid content in the feed liquid after standardization is 35.7%.

[0065] Sterilization: use pasteurization process, temperature...

Embodiment 2

[0072] Ice cream is prepared according to the method of Example 1, the difference is that,

[0073] (1) Ice cream formula: raw milk: 494kg, white sugar: 100kg, skimmed milk powder: 70kg, cream: 200kg, strawberry jam (solid content: 28%): 100kg, coconut oil: 30kg, locust bean gum: 1.2kg, Xanthan gum: 0.6kg, sodium carboxymethylcellulose: 0.6kg, glyceryl monostearate: 1.2kg, citric acid: 1kg, flavor: 1.0kg.

[0074] (2) The solid content of raw milk after standardization is 11.6%.

[0075] (3) After the standardization of raw materials, the solid content in the feed liquid is 35.1%.

[0076] According to the ice cream formula provided in this embodiment, through the above production process, a kind of ice cream without adding water can be obtained. The ice cream has a delicate taste, soft and smooth taste, and rich nutritional value.

Embodiment 3

[0078] Ice cream is prepared according to the method of Example 1, the difference is that,

[0079](1) Ice cream formula: raw milk: 295kg, white sugar: 100kg, skimmed milk powder: 70kg, cream: 150kg, mango puree (15% solid content): 350kg, coconut oil: 30kg, locust bean gum: 1.2kg , Xanthan gum: 0.6kg, sodium carboxymethylcellulose: 0.6kg, glyceryl monostearate: 1.2kg, citric acid: 0.5kg, essence: 0.5kg.

[0080] (2) The solid content of raw milk after standardization is 11.4%.

[0081] (3) After the standardization of raw materials, the solid content in the feed liquid is 33.3%.

[0082] According to the ice cream formula provided in this embodiment, through the above production process, a kind of ice cream without adding water can be obtained. The ice cream has a delicate taste, soft and smooth taste, and rich nutritional value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com