Production method of freeze-dried milk powder

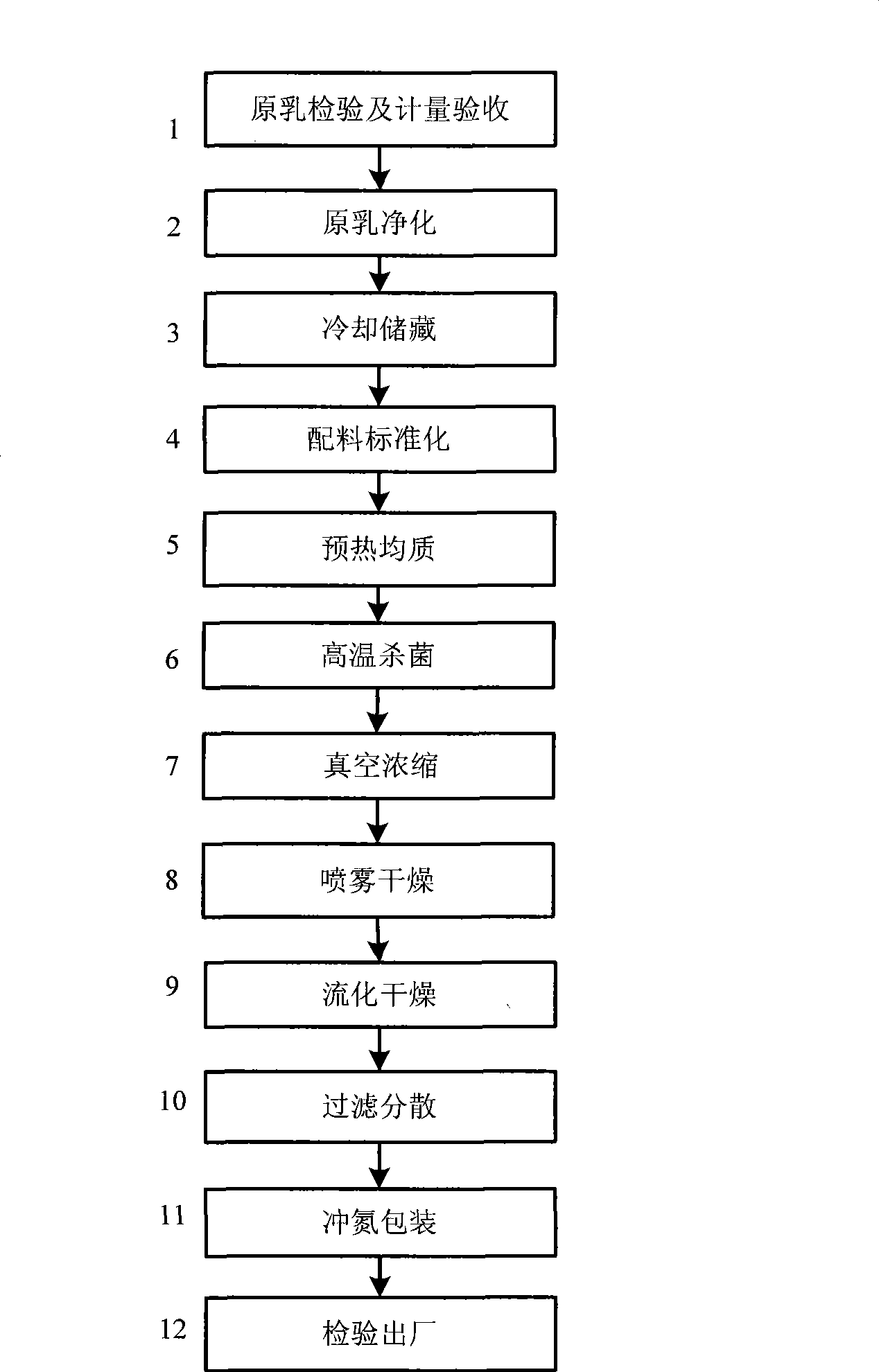

A production method and technology of milk powder, which are applied in the direction of milk preparations, other dairy products, dairy products, etc., can solve the problems of milk powder solubility, poor preparation, scaling, and difficult control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

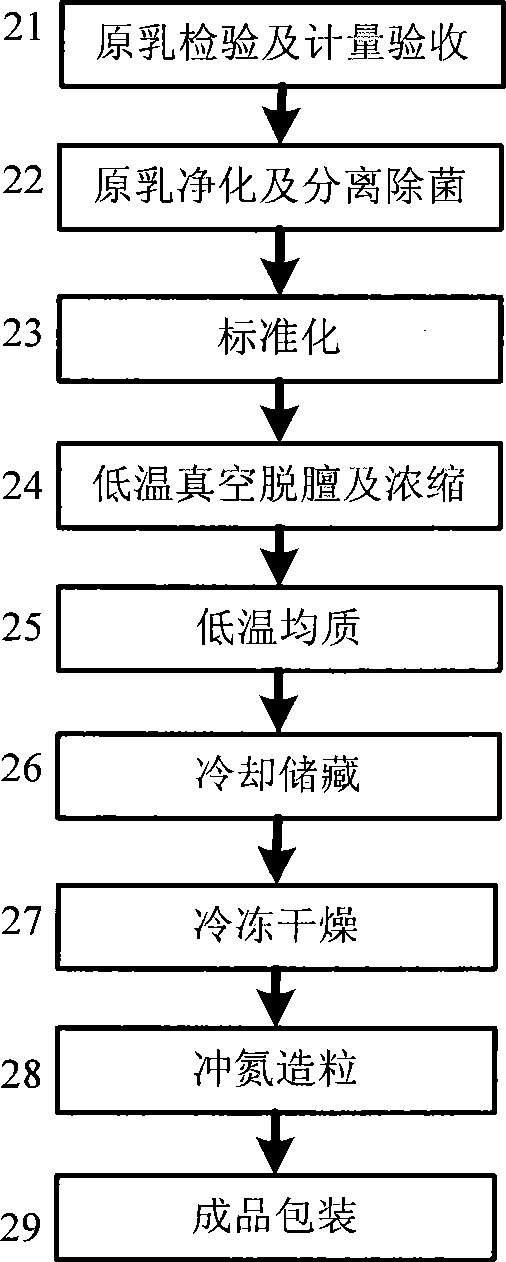

[0046] This embodiment provides a method for producing low-temperature freeze-dried milk powder, which uses low-temperature freeze-drying to produce milk powder, specifically including the following steps:

[0047] Purify, separate and sterilize the raw milk and standardize it to obtain standardized milk. Specifically, the raw milk is subjected to centrifugal sterilization and purification treatment at a temperature of 45-50°C and a high speed of 6000-8000 rpm. After the treatment, the purified milk The total number of colonies in the milk is not higher than 30,000 / ml, and the purified milk is standardized to obtain standardized milk.

[0048]Under the vacuum pressure of -0.085 ~ -0.095Mpa, the moisture in the standardized milk is vaporized at a temperature of 45 ~ 50 ° C, and the smelly ingredients and a large amount of moisture in the standardized milk are vacuum removed, so that the concentrated milk obtained The dry matter content of milk accounts for at least 45% to 50% o...

Embodiment 2

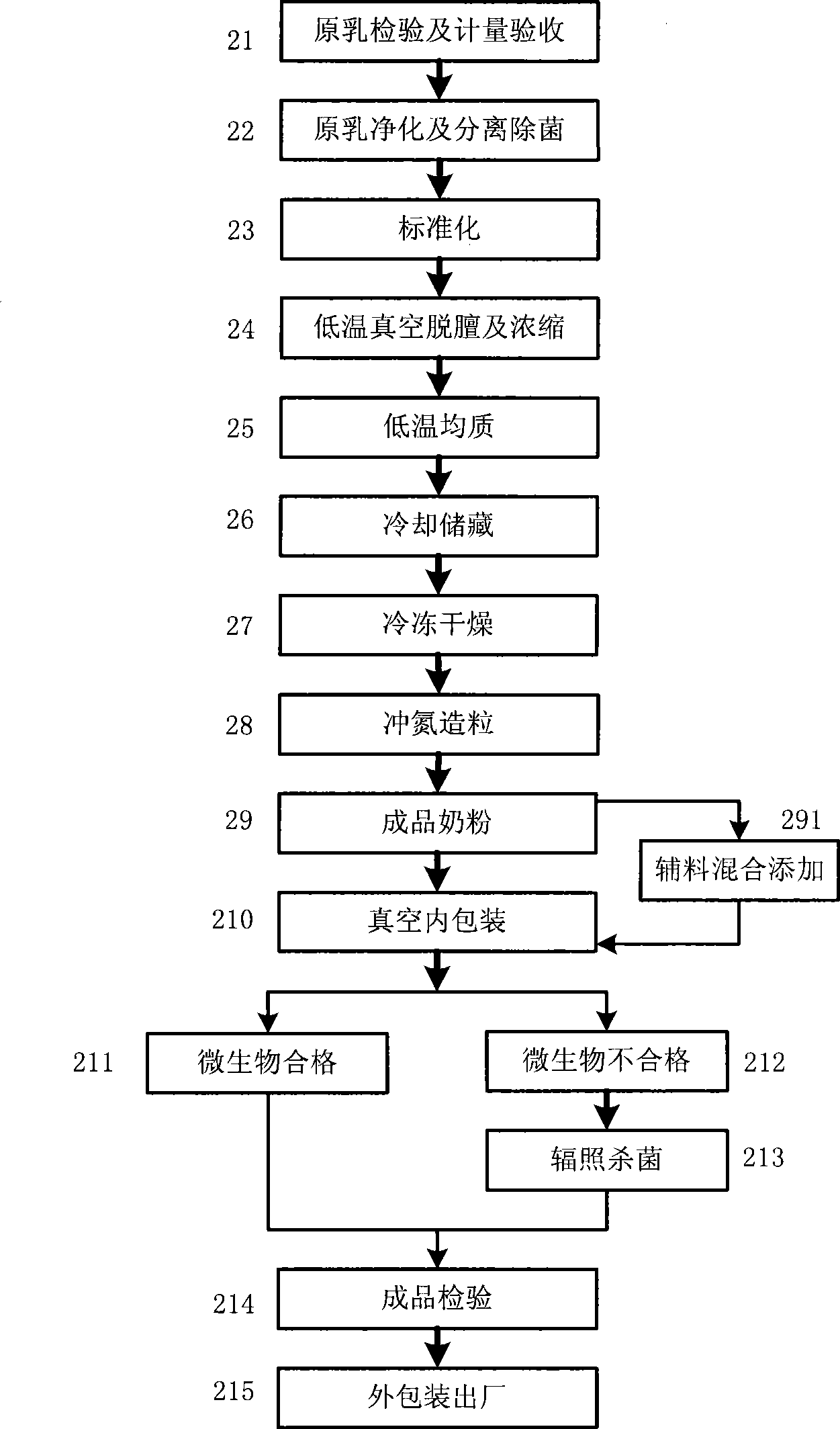

[0112] In the present embodiment, a kind of production method that carries out freeze-dried milk powder in practice is provided, specifically as Figure 4 Shown:

[0113] Wherein the effect of each process step is specifically as follows:

[0114] (31) Raw milk inspection and measurement acceptance: inspect raw milk according to the requirements of relevant standards and measure acceptance.

[0115] (32) Purification, separation and sterilization of raw milk: the temperature of clean milk sterilization should be controlled at 48°C; the speed of the centrifuge should be at 7000 rpm; ;

[0116] (33) Standardization: control range: fat 3.1-3.3%; protein 2.9-3.1%; dry matter content 12-13%;

[0117] (34) Low-temperature vacuum demutation and concentration: primary concentration: vaporize and evaporate the water in the milk at a temperature of 42°C under a vacuum pressure of -0.085Mpa, pump the concentrated milk into a secondary concentration tower, Under pressure, the water in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com