Adding substance for reducing furnace tube deposition coking and improving liquid yield of delayed coker

A technology of delayed coking and additives, applied in cracking, non-catalytic thermal cracking, treatment equipment corrosion/fouling inhibition, etc. It can solve the problems of lack of ashless non-metallic dispersant and unsatisfactory effect, so as to increase liquid recovery and improve Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Mix 9kg of monoethanolamine and 3kg of vegetable oleic acid, heat up to 170°C, and keep stirring, the reaction water is taken out with toluene, when no more reaction water is produced, stop the reaction, evaporate the toluene, and cool naturally to normal pressure , That is, ashless non-metallic dispersant. Then mix 5kg of ashless non-metallic dispersant, 20kg of thermal cracking initiator, 25kg of chemical reaction inhibitor, 30kg of anti-scorch agent and 5kg of solvent, and stir at 90°C for 1.5 hours. Then it is cooled to normal temperature and sent to filter to remove solid impurities to obtain the finished additive to be prepared.

Embodiment 2

[0032] Mix 9kg of triethanolamine and 3kg of vegetable oleic acid, heat up to 170°C, and keep stirring, the reaction water is taken out with toluene, when no more reaction water is produced, stop the reaction, evaporate the toluene, and cool naturally to normal pressure , That is, ashless non-metallic dispersant. Then mix 5kg of ashless non-metallic dispersant, 20kg of thermal cracking initiator, 25kg of chemical reaction inhibitor, 30kg of anti-scorch agent and 5kg of solvent, and stir at 90°C for 1.5 hours. Then it is cooled to normal temperature and sent to filter to remove solid impurities to obtain the finished additive to be prepared.

Embodiment 3

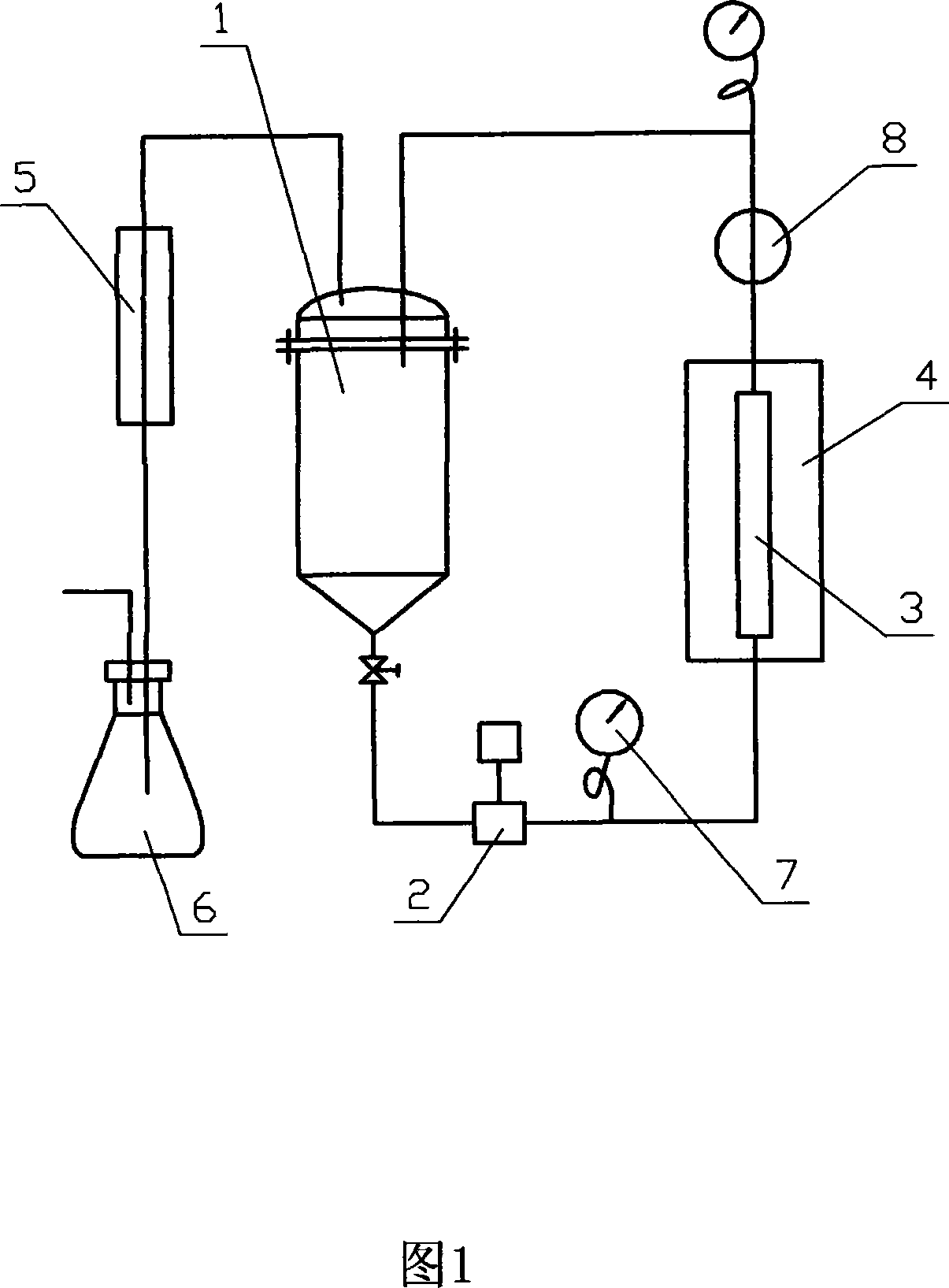

[0034] a. Evaluation method of scale and coke reduction effects of additives, the test device is shown in Figure 1.

[0035] b. Main instruments and equipment are shown in Table 1

[0036] Table 1 Main instruments and equipment of scale reduction and coke reduction test device

[0037] serial number

name

Model / Specification

place of origin

1

2

3

4

Heating furnace tube

Tubular temperature controlled heating furnace

Inner diameter 150, height 400 stainless steel

Cylindrical container

J-W 0.5 / 32

4mm inner diameter stainless steel pipe

Temperature control 300±5℃, read

Number accuracy 0.1°C

self made

Hangzhou Zhijiang Petrochemical Co., Ltd.

equipment co., ltd.

self made

self made

[0038] 5

6

7

cooling condenser

Coker Light Oil Receiver

pressure gaug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com