Waste lubricating oil debrominating agent and preparation method thereof

A waste lubricating oil and debromination agent technology, applied in chemical instruments and methods, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of high production cost, poor stability, and restrictions on large-scale industrial production of 7-DHC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 472.6g silica sol (SiO 2 content of 30%), 27.0g zinc chloride, 52.8g zirconium sulfate, 27.4g molybdenum nitrate, 5.0g tetraethylammonium bromide and 600g water, stir for 6h, mix well, get the initial sol-gel mixture, the initial sol-gel The rubber material was moved into a synthesis kettle and sealed, crystallized at 230°C for 30 hours, and the pH value of the crystal slurry was adjusted to 8.5. After the reaction was completed, the above slurry was added to a flocculant for precipitation, filtered, washed, dried, and extruded to shape. After 120 Dry at ℃ for 5 hours, spray 660g of isobutanol solution with a mass fraction of 3.9% copper chloride and 0.1% dysprosium sulfate in the spraying device to modify the debromination agent, after spraying, roast at 400°C for 3 hours, and then pass in water vapor , the volume ratio of water vapor to air is 1:10, keep the temperature at 550°C for another 3h, then stop the introduction of water vapor, and continue roasting at 480°C ...

Embodiment 2

[0019] 472.6g silica sol (SiO 2 content of 30%), 71.6g of zinc sulfate, 17.2g of zirconium sulfate, 7.64g of molybdenum dichloride hexahydrate, 5.0g of tetraethylammonium bromide and 600g of water, stirred for 6h, and mixed uniformly to obtain the initial sol-gel mixture, The initial sol-gel material is transferred into a synthesis kettle and sealed, crystallized at 260°C for 12 hours, and the pH value of the crystal slurry is adjusted to 8.5. After the reaction is completed, the above slurry is added to a flocculant for precipitation, filtered, washed, dried, and extruded. , dried at 160°C for 5 hours, sprayed 260g of isobutanol solution with a mass fraction of 4.8% copper sulfate and 0.1% dysprosium chloride in the spraying device to modify the debromination agent, after spraying, roasted at 480°C for 2 h, Then feed water vapor, the volume ratio of water vapor and air is 1:10, keep the temperature at 550°C for another 3 hours, then stop feeding water vapor, and continue roas...

Embodiment 3

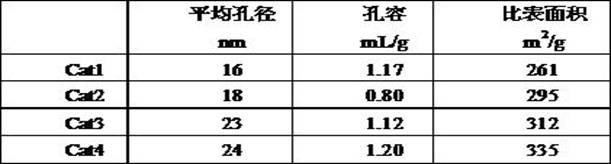

[0021] 484.6g silica sol (SiO 2 content of 30%), 57.2g of zinc nitrate, 39.6g of zirconium sulfate, 26.2g of molybdenum sulfate, 5.0g of tetraethylammonium bromide and 600g of water, stirred for 6 hours, and mixed evenly to obtain the initial sol-gel mixture, the initial sol-gel The material was moved into a synthesis kettle and sealed, and crystallized at 240°C for 18 hours, and the pH value of the crystal slurry was adjusted to 8.5. After the reaction was completed, the above slurry was added to a flocculant for precipitation, filtered, washed, dried, extruded, and heated at 150°C. After drying for 5 hours, spray 360g isobutanol solution with mass fraction of 5% copper nitrate and 0.1% dysprosium sulfate in the spraying device to modify the debromination agent. The volume ratio of steam to air is 1:10, keep the temperature at 550°C for another 3h, then stop the introduction of water vapor, and continue roasting at 480°C for 3h in the air to obtain a specific pore size, large...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com