Matching technology method for optimizing feeding of coal tar suspended bed hydrocracker

A technology for hydrocracking and coal tar, which is used in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc. It can solve the problems of high solid content and high raw material harshness, so as to reduce the raw material harshness, flexibly utilize, and realize products. Diversified Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

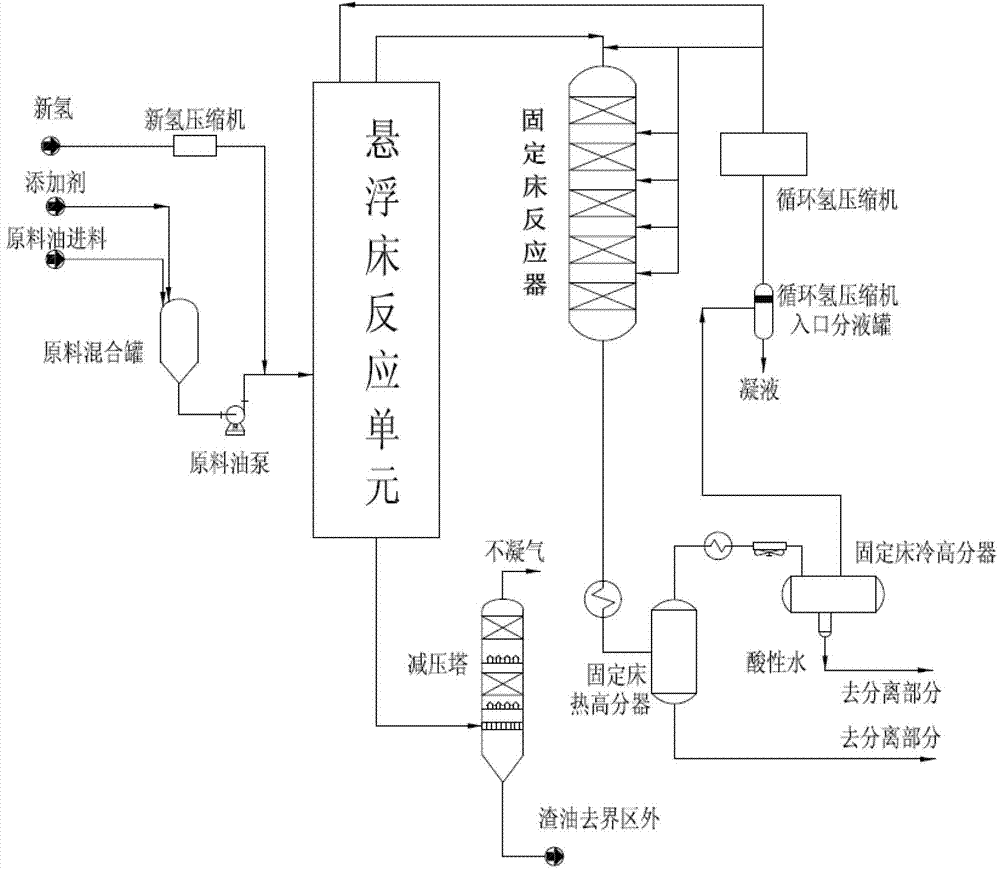

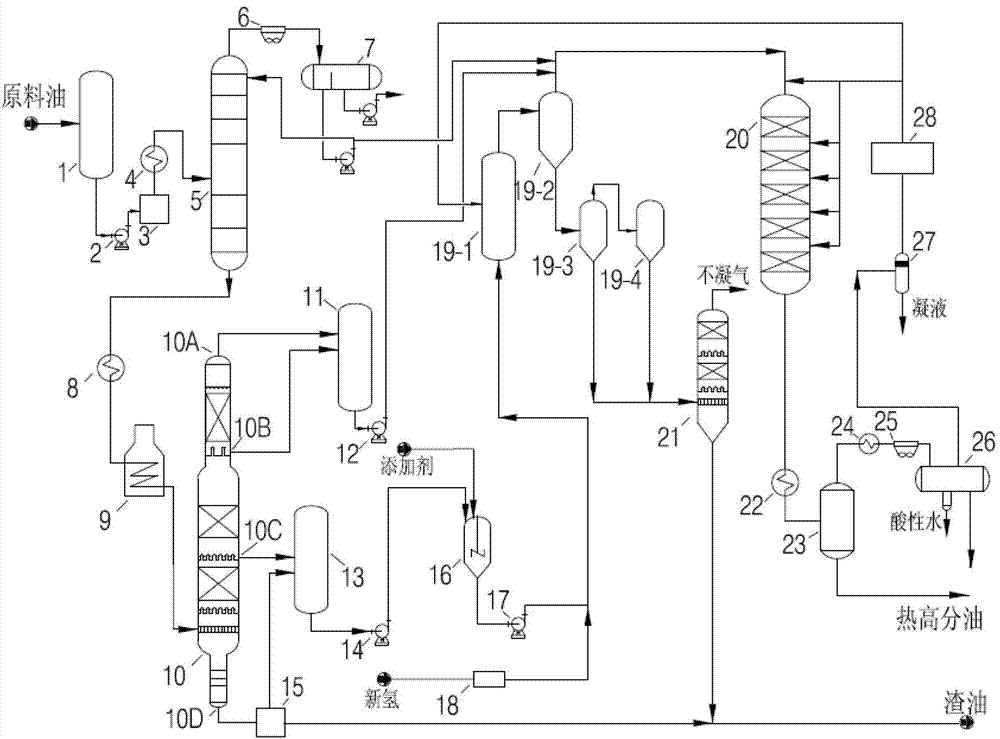

[0063] This embodiment provides a coal tar processing system, the structure of which is as follows figure 2 Shown.

[0064] The coal tar processing system includes: raw oil buffer tank 1, coal tar pump 2, first filter 3, first heat exchanger 4, dehydration tower 5, first air cooler 6, separator 7, and second heat exchange Device 8, coal tar feeding furnace 9, coal tar pressure reducing tower 10, light oil mixing tank 11, light oil pump 12, heavy oil mixing tank 13, heavy oil pump 14, second filter 15, raw material mixing tank 16, raw oil pump 17 , New hydrogen compressor 18, suspended bed reactor unit, fixed bed reactor 20, decompression tower 21, third heat exchanger 22, fixed bed thermal high-pressure separator 23, fourth heat exchanger 24, second air cooler 25. Fixed-bed cold high-pressure separator 26, circulating hydrogen compressor inlet separation tank 27, circulating hydrogen compressor 28, suspended bed reactor unit including suspended bed cracking reactor 19-1, hot hi...

Embodiment 2

[0084] This embodiment provides a coal tar processing method, which uses the coal tar processing device provided in Example 1 for processing, and includes the following steps:

[0085] The coal tar from the tank farm is fed into the raw oil buffer tank 1 at a mass flow rate of 75t / h, and then the coal tar raw material is transported to the first filter 3 by the coal tar pump 2 for filtration, and the coal is removed during the pumping process. The pressure increase of tar is 1.4MPaG;

[0086] The first filter 3 removes solid particles with a particle size ≥25μm in the coal tar, and then the coal tar enters the first heat exchanger 4, the temperature of the coal tar rises to 130°C, and enters the dehydration tower 5 to remove most of the water. The water content of coal tar at the bottom of the tower is about 0.1%. The water leaves from the top of the dehydration tower 5 and brings out a small amount of light oil. After being condensed by the first air cooler 6, it enters the separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com