Selective hydrodesulfurization catalyst containing mesoporous molecular screen and preparation method thereof

A mesoporous molecular sieve, hydrodesulfurization technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor mechanical strength, poor comprehensive performance, poor catalytic stability, etc., and achieve RON loss. Small size, good product selective hydrodesulfurization effect, and moderate reaction process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

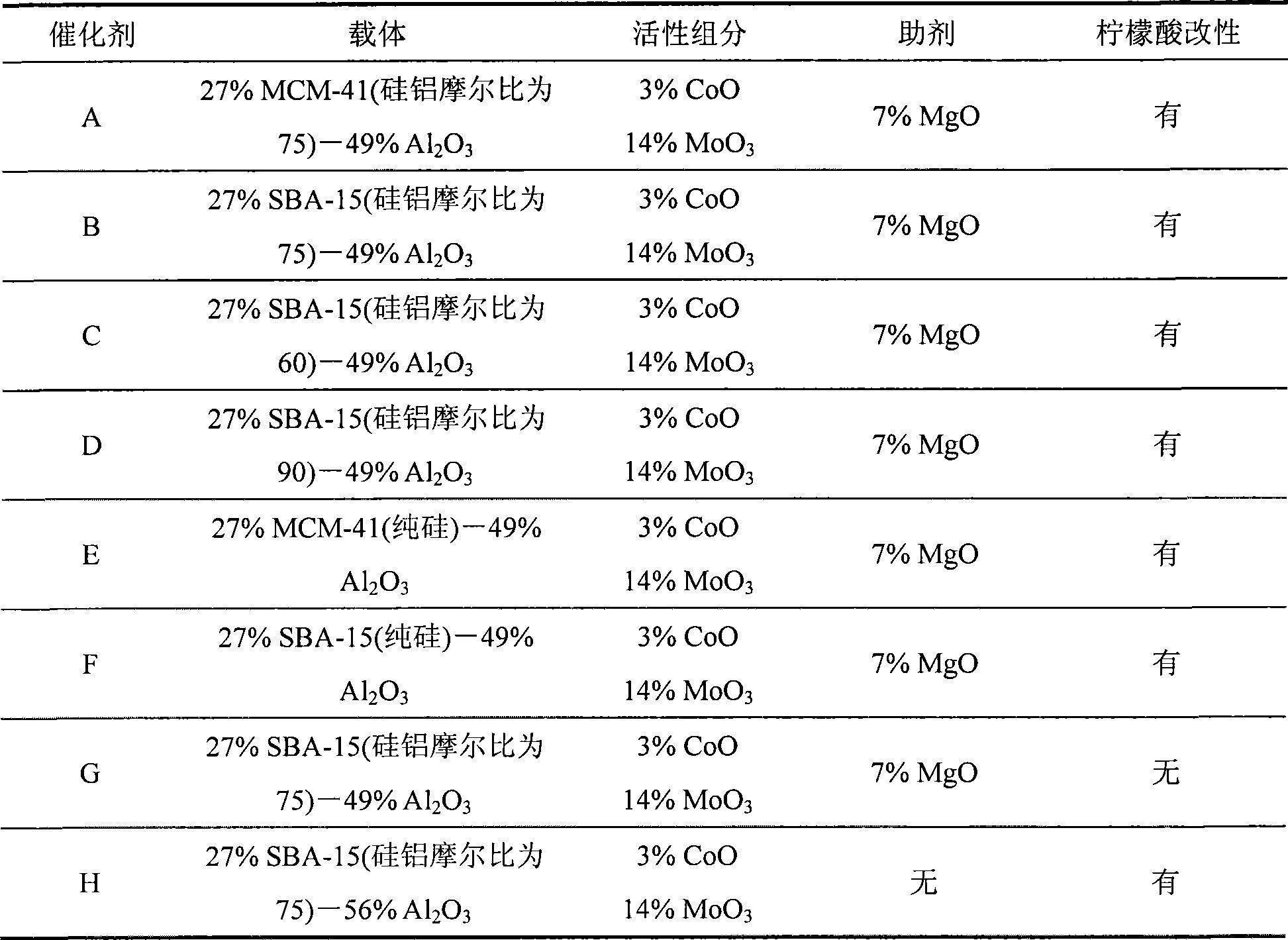

Embodiment 1

[0036] The preparation in this embodiment includes: 3% CoO, 14% MoO based on the total weight of the catalyst 3 , 7% MgO, 27% MCM-41 (the molar ratio of silicon to aluminum is 75)—49% Al 2 O 3 的catalyst A.

[0037] Weigh 43.9 grams of SB (pseudo-boehmite) powder (produced by Condea, Germany, with water content of 26wt%), MCM-41 molecular sieve (specific surface area of 800m) with a silicon-to-aluminum molar ratio of 75 2 / g) 17.9 grams, 2 grams of Sesbania powder, grind and mix them evenly, add 3.7 grams of nitric acid solution with a mass concentration of 65% and 30 grams of deionized water, fully kneaded and squeeze into an extruder to form a diameter of about 1.5 mm The cylindrical shape is dried at 120°C for about 3 hours, calcined at 520°C for about 5 hours, and then sieved after cooling to produce MCM-41 / Al with a length of about 2mm. 2 O 3 combination.

[0038] Then add 40 grams of the above MCM-41 / Al 2 O 3 The composition was immersed in 48 mL of a solution containing 2....

Embodiment 2

[0041] The preparation in this embodiment includes: 3% CoO, 14% MoO based on the total weight of the catalyst 3 , 7% MgO, 27% SBA-15 (molar ratio of silicon to aluminum is 75)—49% Al 2 O 3 的catalyst B.

[0042] The preparation method is the same as in Example 1, except that the MCM-41 (molar ratio of silicon to aluminum is 75) in the carrier is changed to SBA-15 (molar ratio of silicon to aluminum is 75, and the specific surface area is 780m 2 / g).

Embodiment 3

[0044] The preparation in this embodiment includes: 3% CoO, 14% MoO based on the total weight of the catalyst 3 , 7% MgO, 27% SBA-15 (the molar ratio of silicon to aluminum is 60)—49% Al 2 O 3 的catalyst C.

[0045] The preparation method is the same as in Example 1, except that the MCM-41 in the carrier (the molar ratio of silicon to aluminum is 75) is changed to SBA-15 (the molar ratio of silicon to aluminum is 60, and the specific surface area is 760m. 2 / g).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com