Bicomponent naphtha reforming catalyst and preparation method thereof

A reforming catalyst and catalyst technology, applied in the direction of naphtha catalytic reforming, catalyst activation/preparation, molecular sieve catalyst, etc., can solve the problem of sensitivity to water and sulfur content, low activity of aromatization of low-carbon paraffins, and insufficient stability Ideal and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

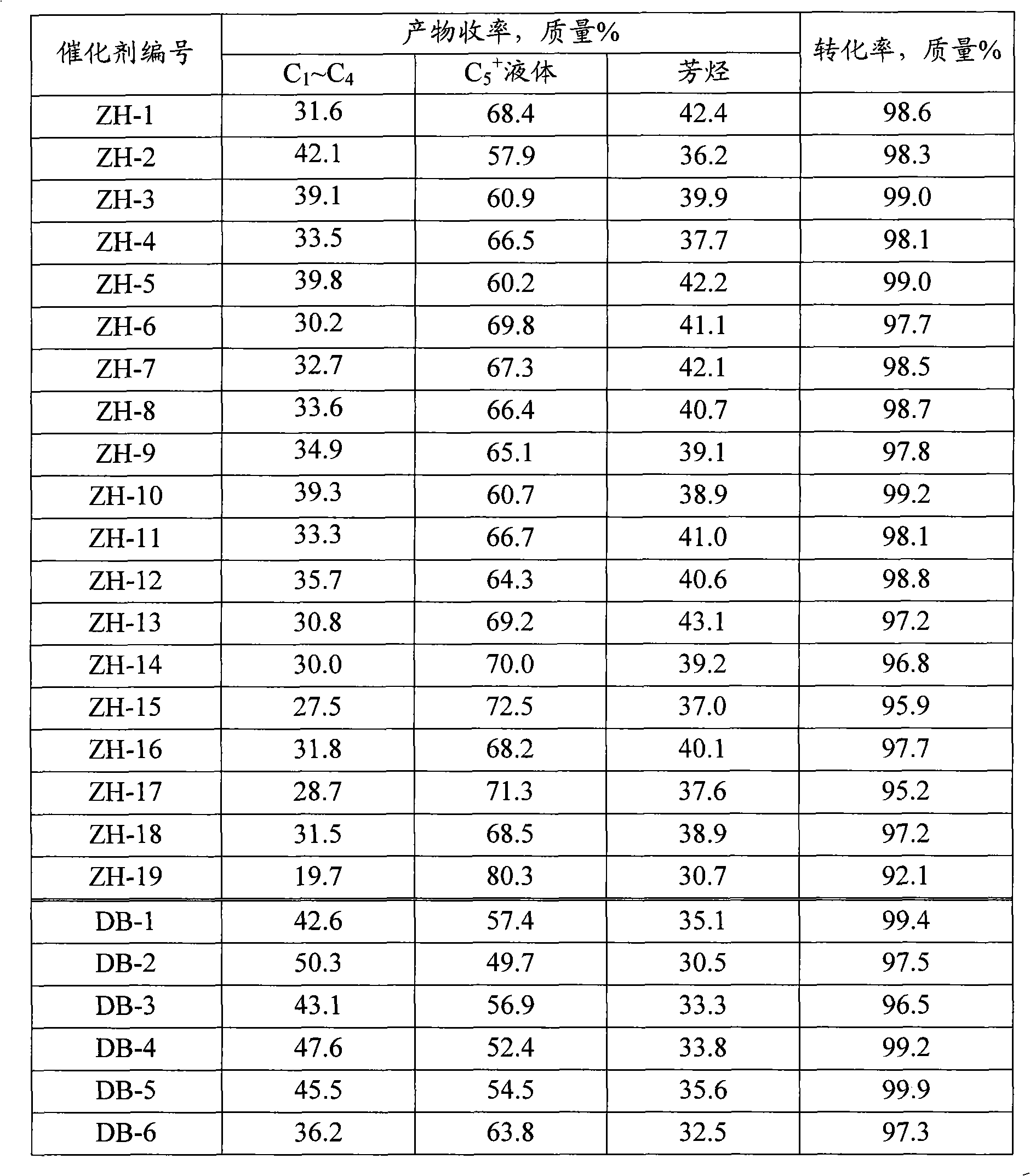

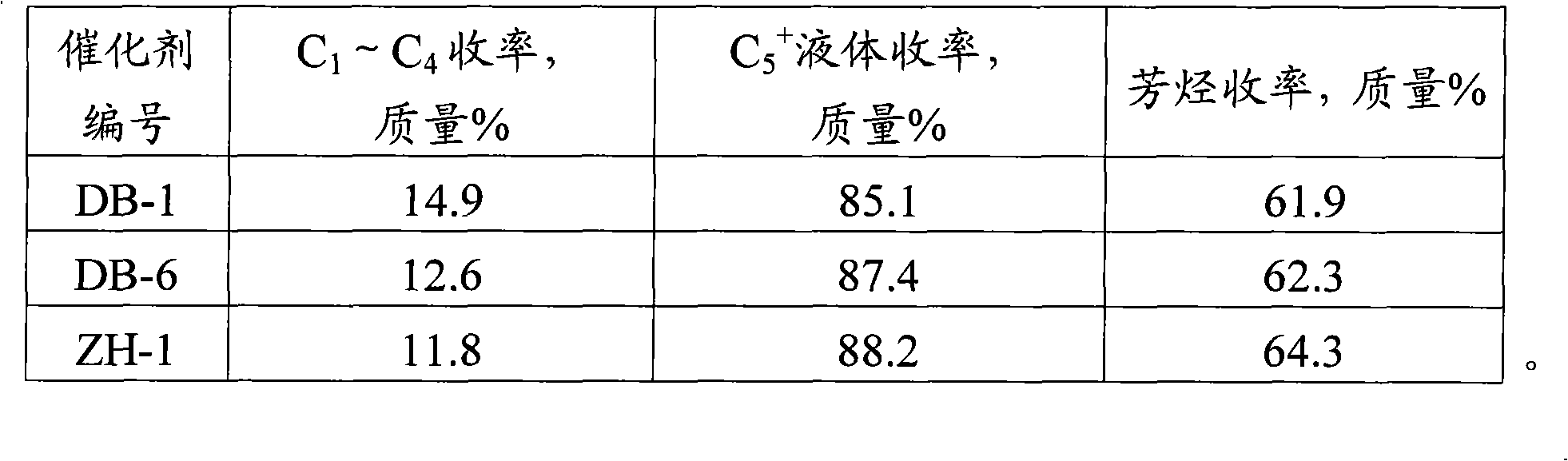

Examples

preparation example Construction

[0024] The preparation method of catalyst provided by the invention has three kinds, and the first method comprises:

[0025] (1) Perform ion exchange on borosilicate molecular sieves or low aluminum borosilicate molecular sieves with a solution containing platinum ions, dry, roast, and reduce the solids after exchange to obtain a powdery molecular sieve catalyst,

[0026] (2) Compounds containing platinum group noble metals and VIIB group metal compounds in anions are used to make impregnation solution, impregnating spherical or powdery alumina carrier, drying and roasting the impregnated solid to obtain alumina catalyst,

[0027] (3) The molecular sieve catalyst prepared in step (1) and the alumina catalyst prepared in step (2) are uniformly mixed and shaped according to the mass ratio of 1-9:9-1.

[0028] The second preparation method of catalyst provided by the invention comprises:

[0029] (1) Add extrusion aids to borosilicate molecular sieves or low-aluminum borosilica...

example 1

[0047] (1) Preparation of borosilicate β molecular sieve.

[0048] 1.0g borax, 1.1g sodium hydroxide and 104.7g concentration are the tetraethylammonium hydroxide solution of 25% by mass and mix homogeneously, then add 20g ultramicro silicon dioxide (produced by Cabot company, trade mark CAB-O-SILM-5 ), stirred evenly and moved into the reaction kettle, and crystallized at 140°C for 15 days. After the crystallization is completed, it is rapidly cooled to 40°C. After the product is centrifuged and washed, the obtained solid is dried at 90°C for 10 hours to obtain the original borosilicate β molecular sieve powder. Its anhydrous chemical composition (calculated by oxide molar ratio) is: 0.5 Na 2 O·B 2 o 3 22SiO2 2 .

[0049] (2) Preparation of molecular sieve catalyst.

[0050] Pt(NH 3 ) 4 Cl 2 Prepare an impregnating solution with an appropriate amount of deionized water, so that the impregnating solution contains 1.0% by mass of Pt (relative to the mass of the molecul...

example 2

[0056] (1) Preparation of borosilicate ZSM-5 molecular sieve.

[0057] Mix 3.2g of borax, 2.0g of NaOH, 61g of tetraethylammonium hydroxide solution with a concentration of 10% by mass and 224ml of deionized water evenly, add 50g of ultrafine silicon dioxide under stirring, vigorously stir evenly, and age at 60°C for 4 hours. Move it into a reaction kettle, crystallize at 150°C for 5 days, and then cool it down to 40°C quickly. The product is centrifuged and washed until the pH value is 8-9, and the solid obtained is dried at 120°C for 10 hours to obtain borosilicate ZSM-5 molecular sieve powder. Anhydrous chemical composition (based on oxide molar ratio) is: 0.4Na 2 O·B 2 o 3 ·53SiO2 2 .

[0058] (2) Carry out platinum exchange to the former powder of borosilicate ZSM-5 molecular sieve by the method for example 1 (2), then roast, reduce again, make the borosilicate ZSM- 5 molecular sieve catalyst.

[0059] (3) prepare alumina catalyst by the method for example 1 (3) ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com