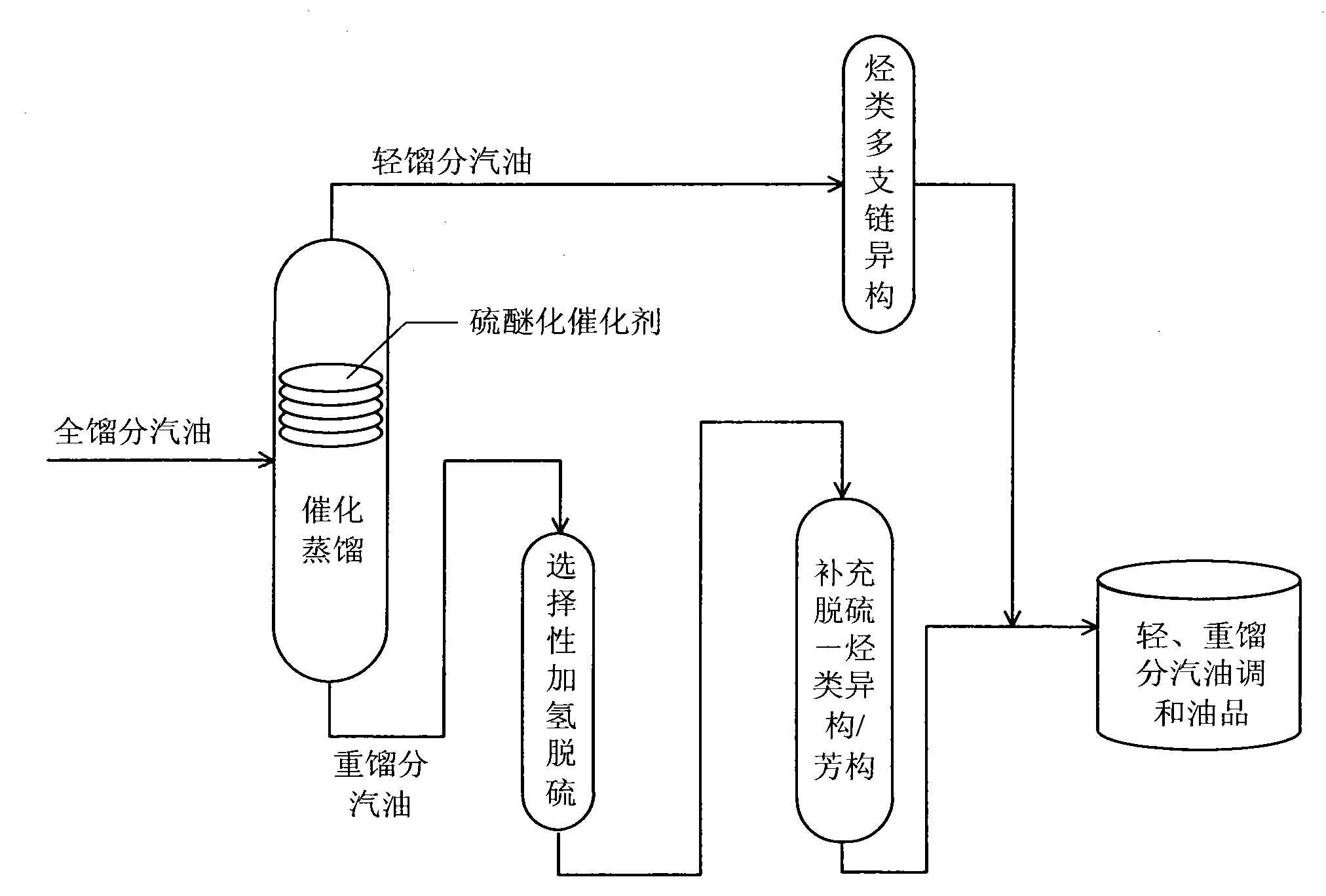

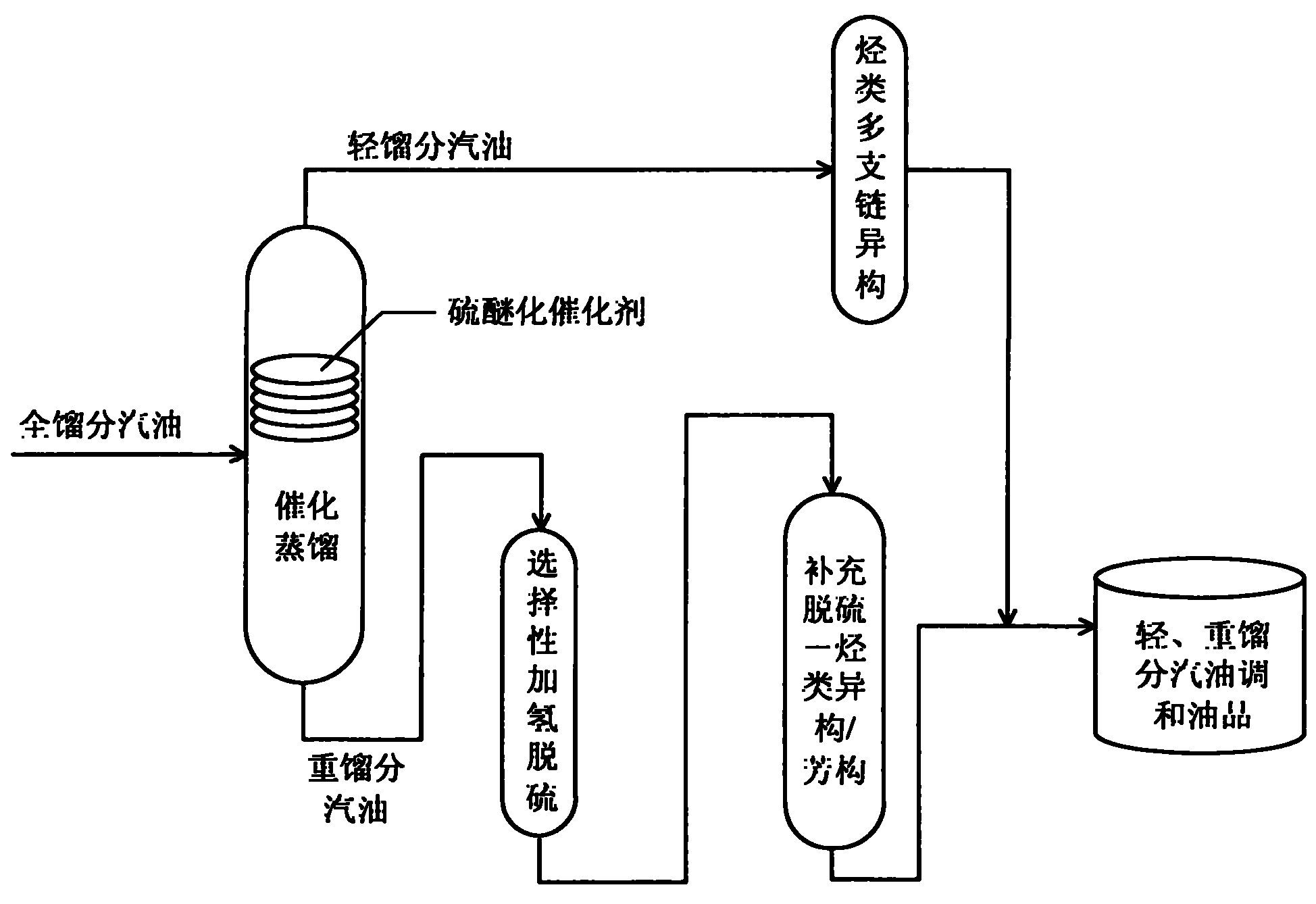

Production method for ultra-low sulfur and high-octane number gasoline

A technology for high-octane gasoline and a production method, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of reduced catalyst strength, unfavorable catalyst stability, and unsatisfactory catalyst stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In this embodiment, the sulfur content is 1750 μg.g -1 , 48.4v% ultra-high-sulfur, high-olefin low-quality full-cut FCC gasoline (full-cut feedstock 1) with an olefin content of 48.4v% was subjected to hydroreforming treatment.

[0046] Wherein, the composition ratio of various catalysts is as follows, respectively based on the total weight of each catalyst:

[0047] Thioetherification catalyst: 16wt% NiO-2wt% K 2 O-2wt%CuO / 30wt%HZSM-5-50wt%Al 2 o 3 -SiO 2 (silicon-containing alumina);

[0048] Hydrocarbon multi-branched isomerization catalyst: 6wt% MoO 3 -3wt%NiO-3wt%CoO / 64wt%SAPO-11-20wt%Al 2 o 3 -4wt%TiO 2 ;

[0049] Selective hydrodesulfurization catalyst: 4wt% CoO-12wt% MoO 3 -3wt%K 2 O-2wt%P 2 o 5 / 67wt%Al 2 o 3 -8wt%TiO 2 -4wt%ZnO;

[0050] Supplementary Desulfurization-Hydrocarbon Isomerization / Aromatization Catalyst: 6wt% MoO 3 -3wt%CoO-3wt%NiO / 50wt%ZSM-5-20wt%SAPO-11-18wt%Al 2 o 3 .

[0051] The concrete preparation steps of thioetherifica...

Embodiment 2

[0083] This example gives a sulfur content of 2210μg·g -1 , The effect of hydroreforming of ultra-high sulfur, high-olefin low-quality full-cut FCC gasoline (full-cut feedstock 2) with an olefin content of 51.3v%.

[0084] Wherein, the composition ratio of various catalysts is as follows, respectively based on the total weight of each catalyst:

[0085] Thioetherification catalyst: 18wt% NiO-2wt% K 2 O-2wt%CuO / 35wt%HZSM-5-43wt%Al 2 o 3 -SiO 2 ;

[0086] Hydrocarbon multi-branched isomerization catalyst: 6wt% MoO 3 -2wt%NiO-3wt%CoO / 65wt%SAPO-11-20wt%Al 2 o 3 -4wt%TiO 2 ;

[0087] Selective hydrodesulfurization catalyst: 3wt% CoO-14wt% MoO 3 -3wt%K 2 O-3wt%P 2 o 5 / 67wt%Al 2 o 3 -5wt%TiO 2 - 5wt% ZnO;

[0088] Supplementary Desulfurization-Hydrocarbon Isomerization / Aromatization Catalyst: 8wt% MoO 3 -4wt%CoO-3wt%NiO / 50wt%ZSM-5-20wt%SAPO-11-15wt%Al 2 o 3 ;

[0089] The preparation method of above-mentioned catalyst is identical with embodiment 1.

[0090] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com