Method for processing inferior heavy oil

A low-quality heavy oil, oil and gas technology, applied in the petroleum industry, processing hydrocarbon oil, hydrocarbon oil processing products and other directions, can solve the problems of low yield of gasoline and diesel, poor product distribution, etc., to achieve simple process, conducive to industrial application, The effect of reducing gas yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

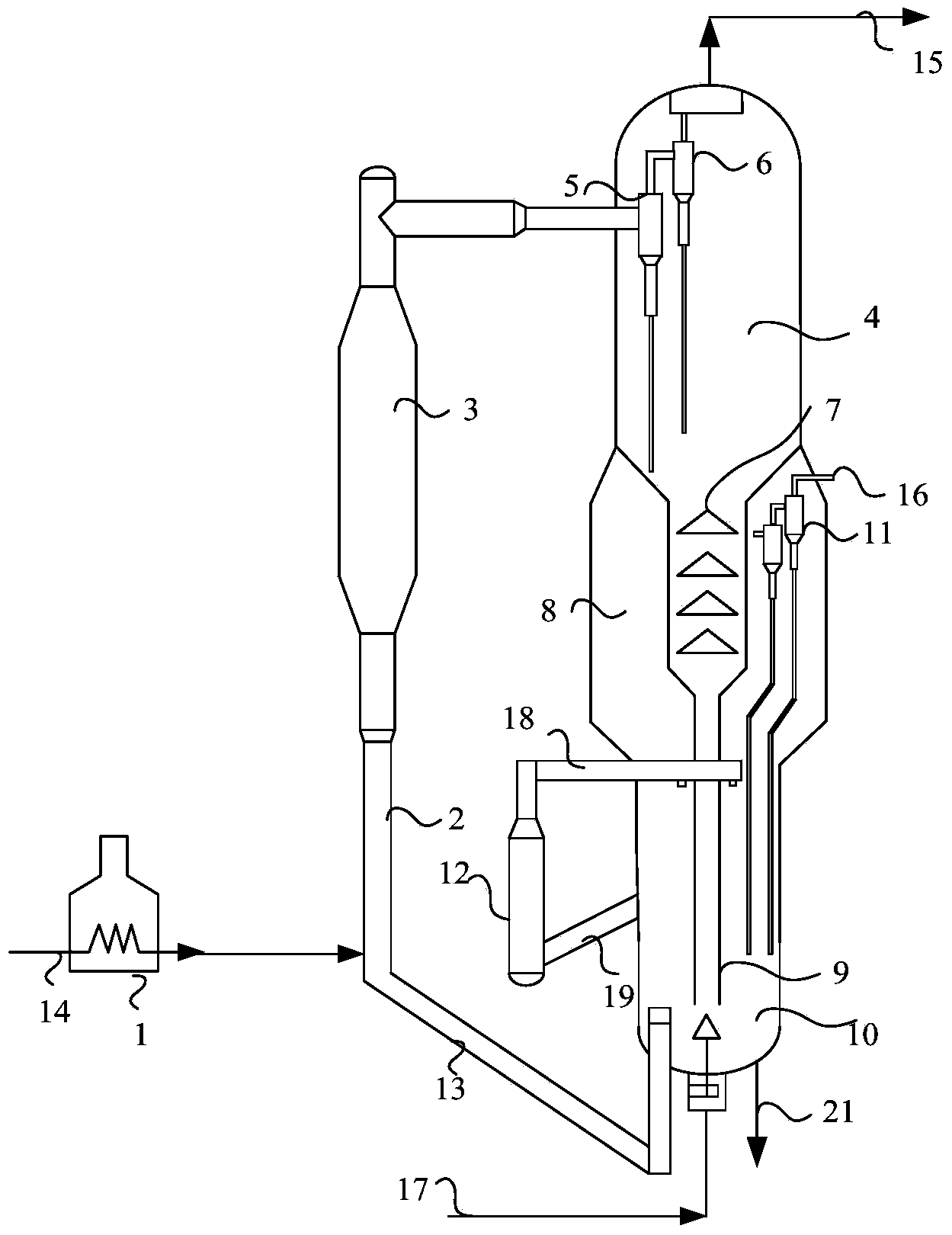

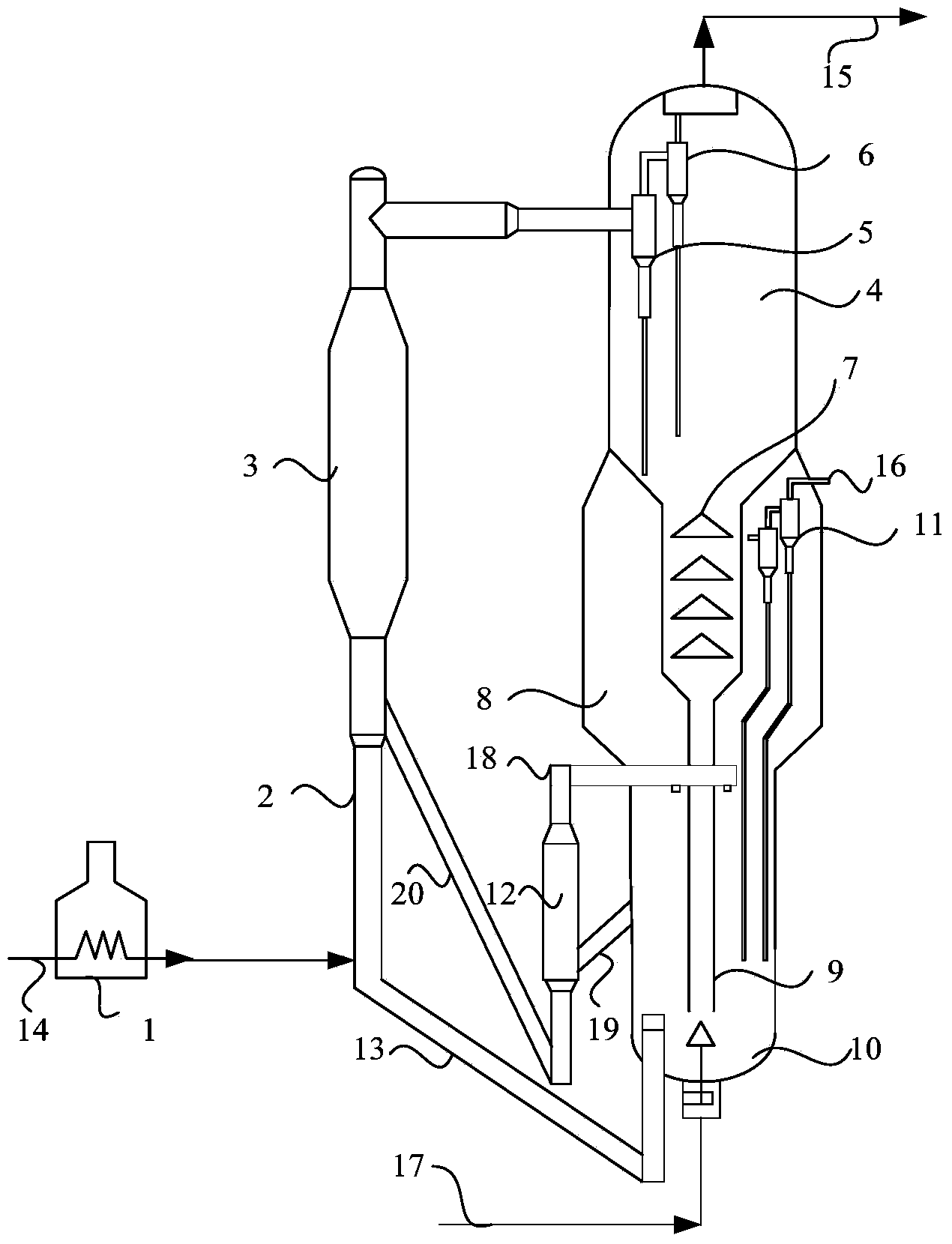

Method used

Image

Examples

Embodiment 1

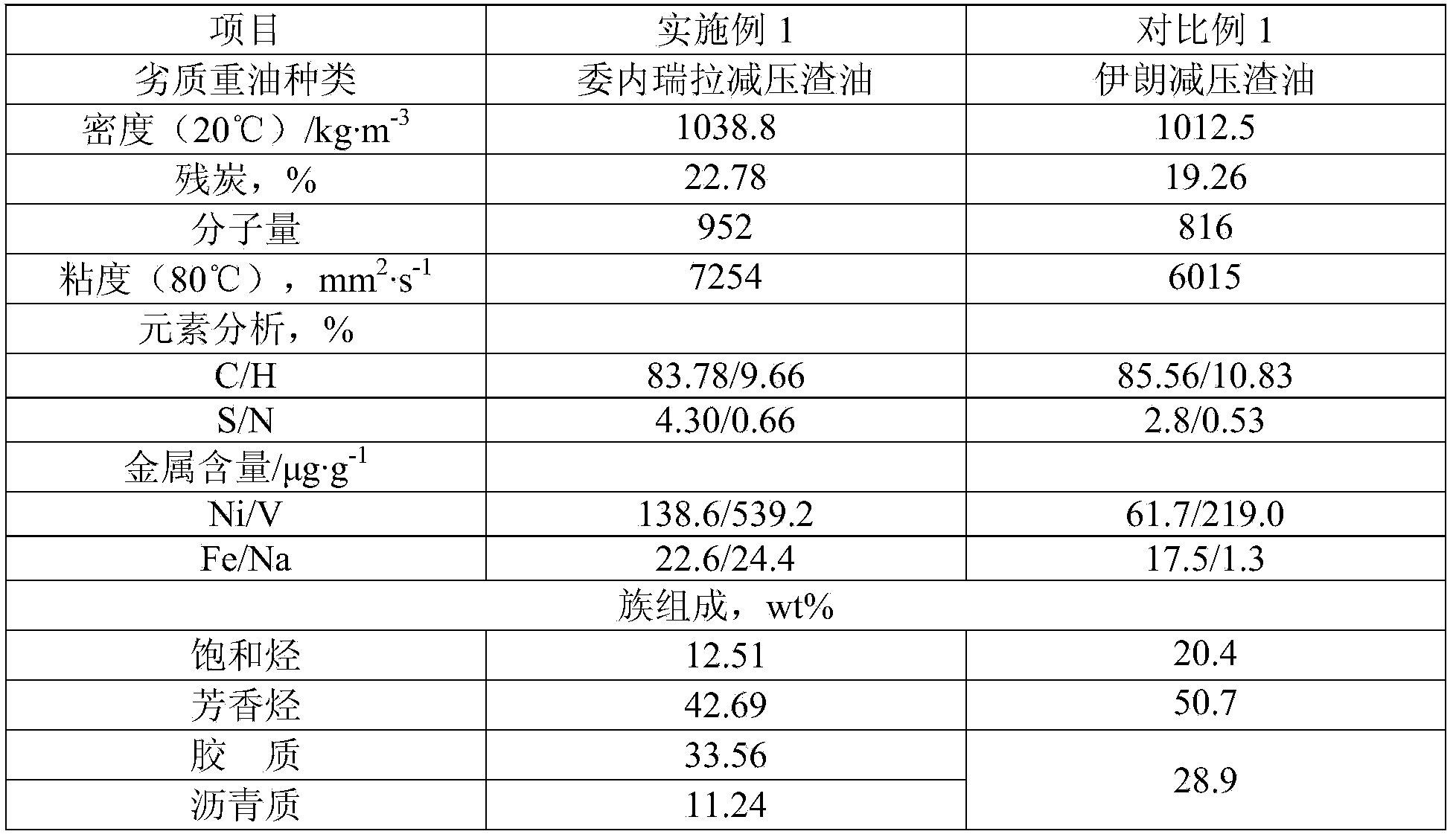

[0048]In order to illustrate the effect of the method of the present invention, the present embodiment adopts the above-mentioned technological process to process Venezuelan vacuum residue. The properties of the solid catalytic particles used as the catalytic contact agent are shown in Table 2, and the properties of the vacuum residue are shown in Table 1.

[0049] The Venezuelan vacuum residue raw material with a residual carbon value of 22.78wt% was preheated to 260°C and introduced into a riser-bed reactor for processing. The relevant parameter control and material balance data of this process are shown in Table 3.

[0050] After preheating the Venezuelan vacuum residue raw material, it is sprayed into the riser bed reactor, mixed and reacted with solid catalytic particles with good surface structure, fluidization performance, pore structure and suitable activity, so that the raw material is catalyzed Residue carbon removal, heavy metal removal and asphaltene removal reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com