Hydro-cracking method for f-t synthetic oil

A technology of hydrocracking and Tropsch synthesis, which is applied in the fields of hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., and can solve problems such as complex reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

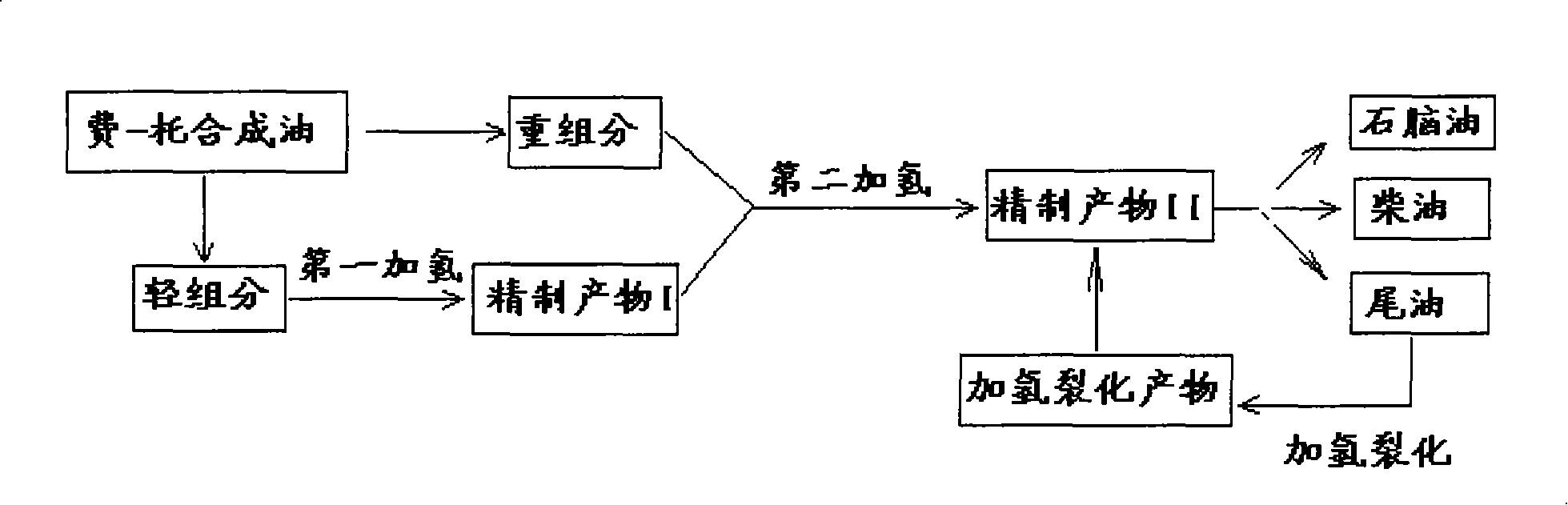

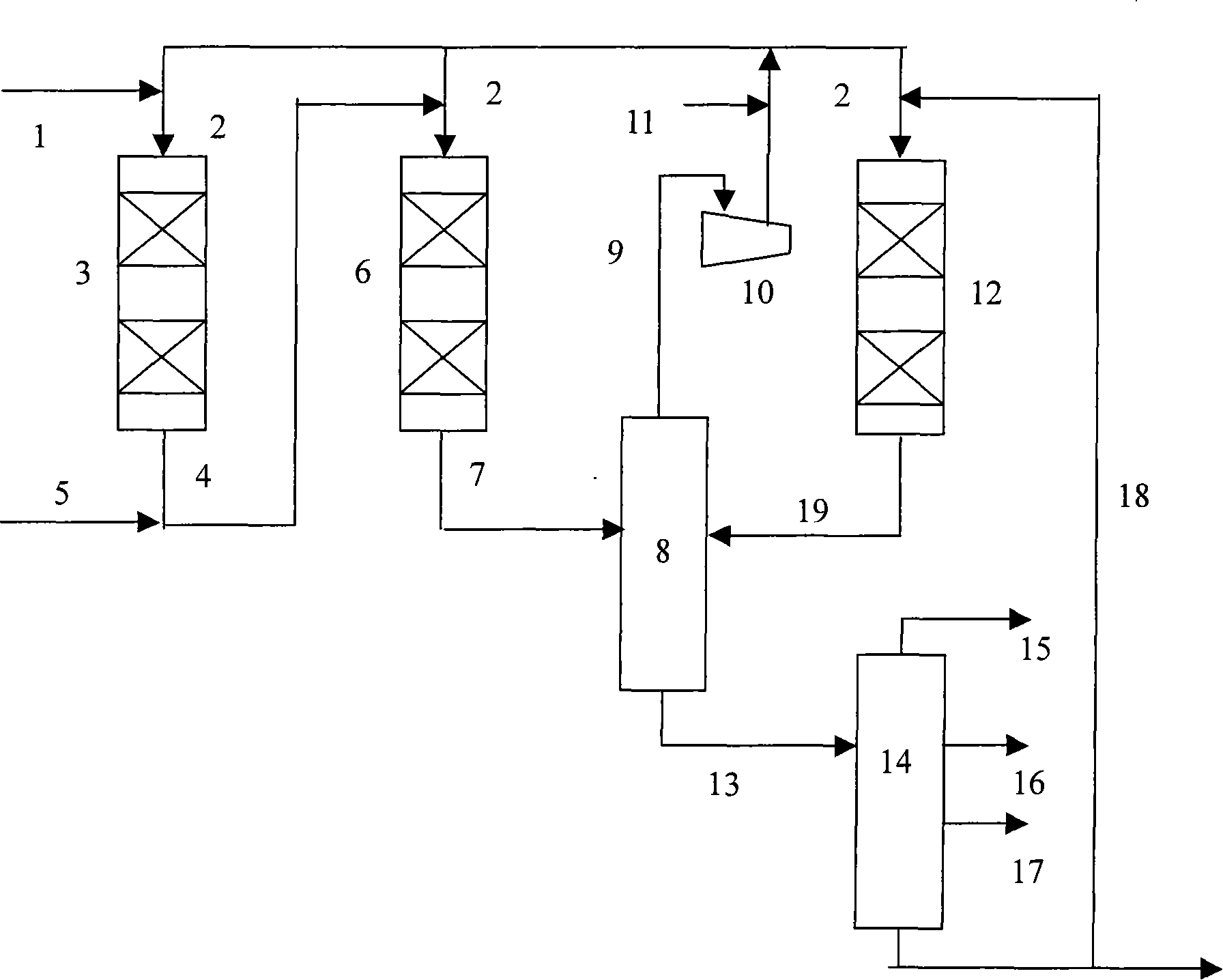

Method used

Image

Examples

Embodiment 1、2、3 and 4

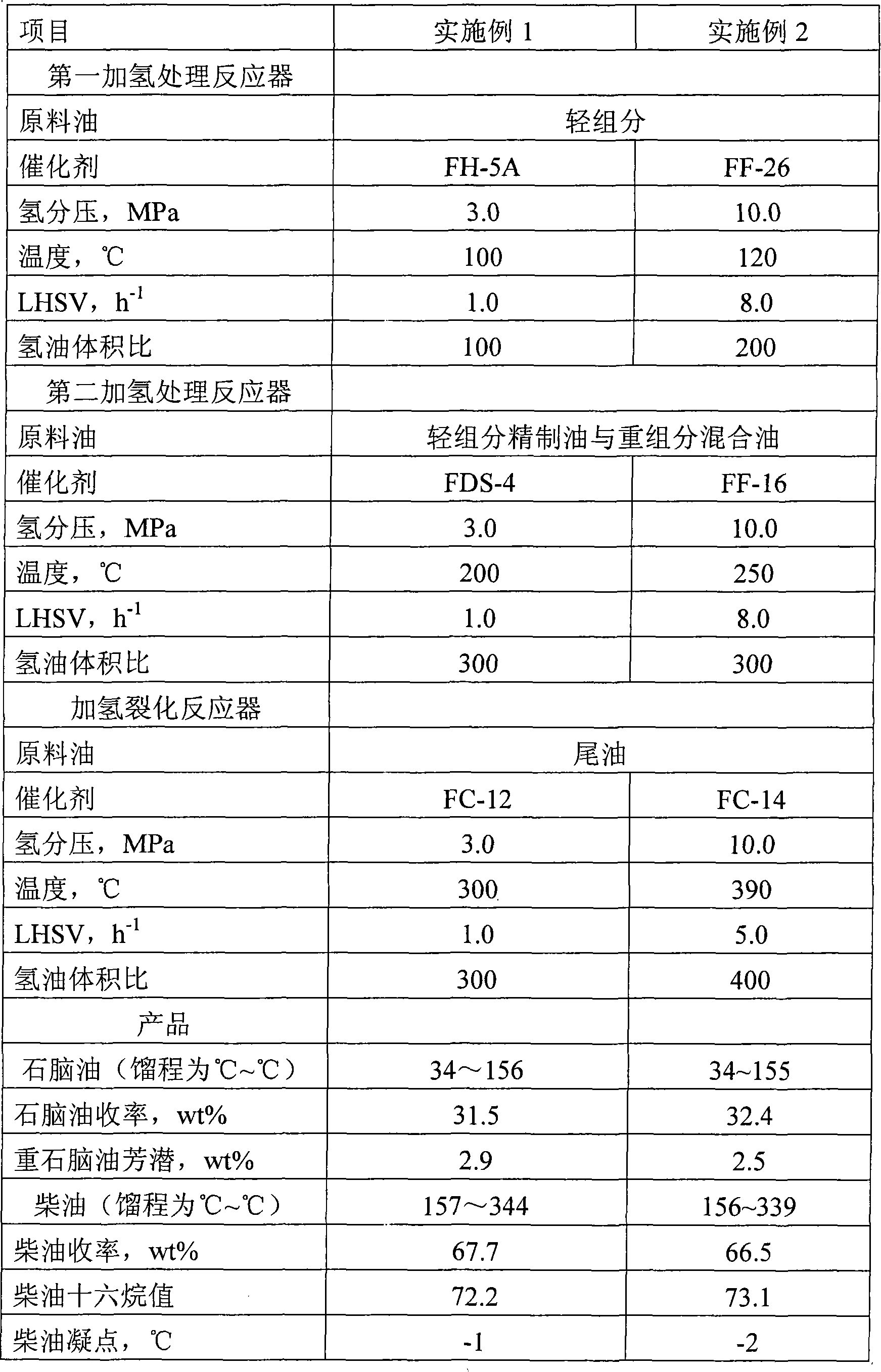

[0049] Embodiment 1, 2, 3 and 4 adopt figure 1 and 2 The described process and the properties of the raw materials used are shown in Table 1. The operating conditions of each reactor and the properties of the products obtained in Examples 1 and 2 are shown in Table 2, and the operating conditions of each reactor in Examples 3 and 4 and the properties of the products obtained are shown in Table 3.

[0050] Table 1 Raw Oil Properties

[0051] Raw oil

light component

heavy component

Density / g·m -3

0.7519

0.8303

Distillation range / ℃

40~180

181~650

Bromine value / gBr (100mL) -1

45.12

Acid value / mgKOH·g -1

0.85

Acidity / mgKOH (100mL) -1

1200

Oxygen content, %

5.3

0.6

Diene, %

22.24

[0052] Table 2 embodiment 1,2 the operating conditions of each reactor and the character of gained product

[0053]

[0054] Note:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com