Coal tar hydrogenation upgrading method

A technology of hydrogenation upgrading and coal tar, which is applied in the fields of hydrogenation treatment process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of reducing the yield and high proportion of naphtha and diesel oil, and achieve full utilization, The effect of increasing the yield and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The coal tar used in this example is a low-temperature coal tar, and its properties are listed in Table 2.

[0056] Table 2

[0057] Density (20℃), g / cm 3

1.05

Sulfur, mg / kg

2100

Nitrogen, mg / kg

8200

Oxygen content, wt%

4.16

Viscosity (50℃), mm 2 ×s -1

7.45

Asphaltene, wt%

17.8

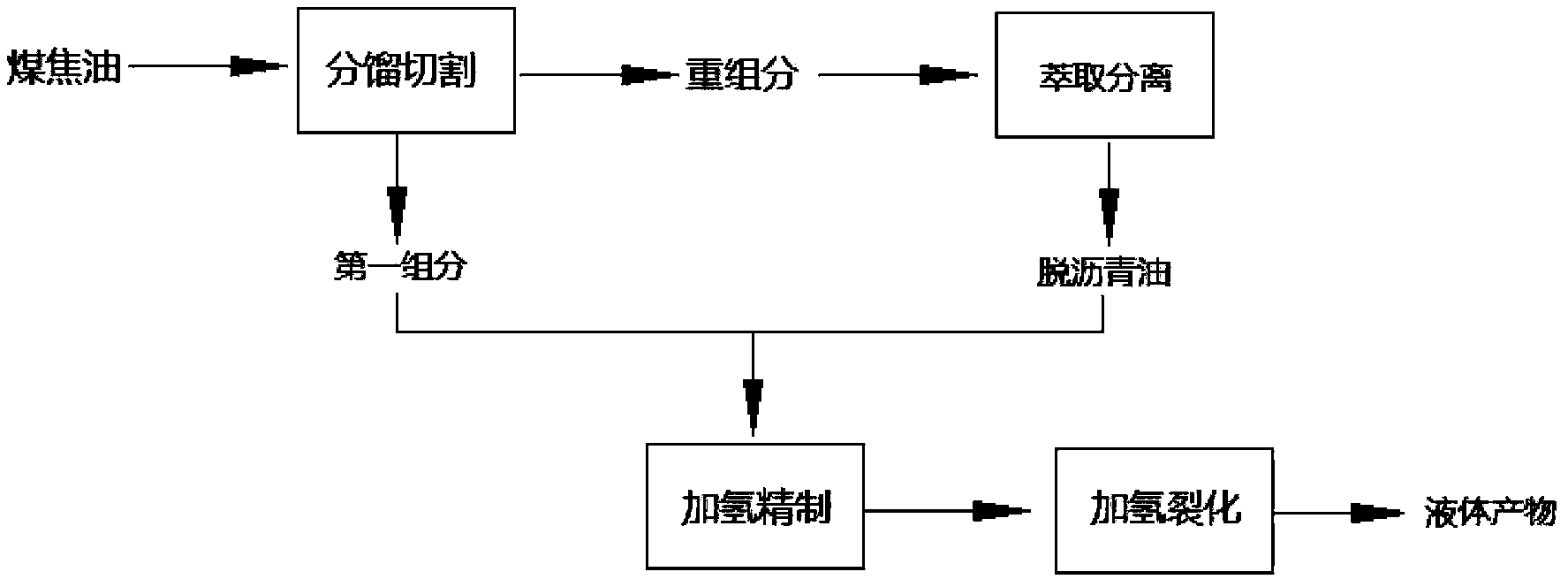

[0058] use figure 1 The process shown is for hydrotreating and upgrading of coal tar.

[0059] (1) Using a real boiling point distillation apparatus, 1 kg of coal tar is fractionated and cut to obtain the first component and the heavy component. The content of the component is 60% by weight. The properties of the resulting first and heavy fractions are listed in Table 3.

[0060] (2) Mix the heavy component obtained in step (1) with n-pentane at a weight ratio of 1:6 for extraction and separation to obtain an extract phase and a raffinate phase. Wherein, the extraction conditions include: the temperature is 50...

Embodiment 2

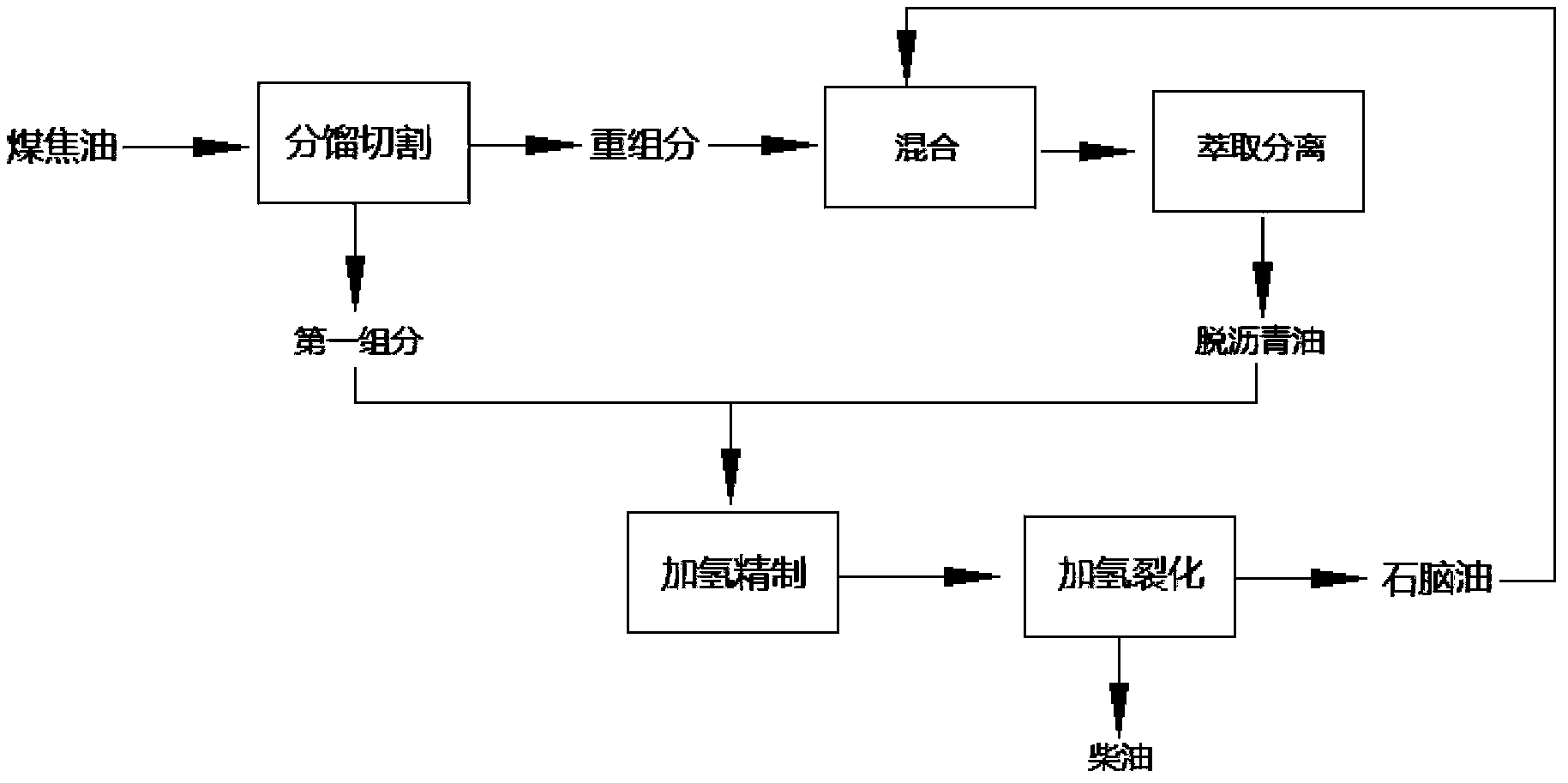

[0066] The same method as in Example 1 is used to carry out hydrogenation and upgrading of coal tar, the difference is that according to image 3 The process flow shown is carried out. In step (2), the heavy component is mixed with the naphtha obtained in step (3) in a weight ratio of 1:3, and the obtained mixture is mixed with n-pentane in a weight ratio of 1:3. extraction.

[0067] The properties of the obtained first fraction, heavy fraction and deasphalted oil are listed in Table 3. In step (3), based on the total amount of coal tar as a raw material, the total yield of naphtha and diesel oil is 80% by weight; the hydrogenation unit can still run continuously for more than 500 hours without changing the catalyst. Obtain naphtha and diesel oil of up to standard quality.

Embodiment 3

[0069] Coal tar is hydrogenated and upgraded in the same way as in Example 2, the difference is that in step (1), the fractionation cutting temperature is 380°C; based on the total amount of coal tar used as raw material, the content of heavy components is 55% by weight; in step (2), the extraction is carried out under the supercritical state of the extractant, and the specific conditions are: the temperature is 175° C., and the pressure is 4.5 MPa.

[0070] The properties of the obtained first fraction, heavy fraction and deasphalted oil are listed in Table 3. In step (3), based on the total amount of coal tar as a raw material, the total yield of naphtha and diesel oil is 90% by weight; the hydrogenation unit can still run continuously for more than 500 hours without changing the catalyst. Obtain naphtha and diesel oil of up to standard quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com