System and method for treating pulverized coal and biomass

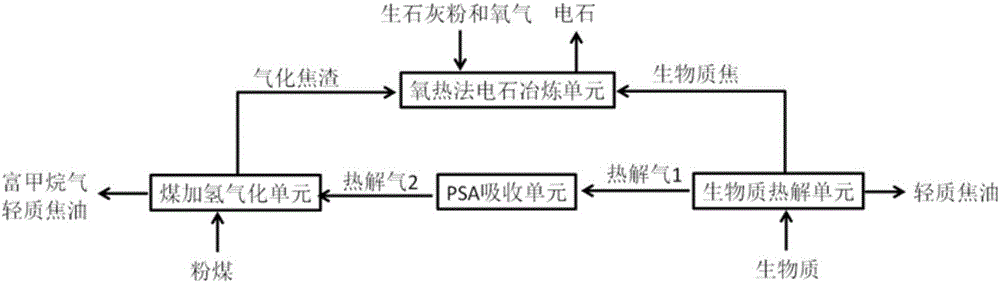

A technology of biomass and biomass coke, which is applied to the gasification of biofuels, carbides, and granular/powdered fuels. Solve problems such as gas biomass coke, achieve the effect of improving heat utilization rate, reducing energy consumption and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

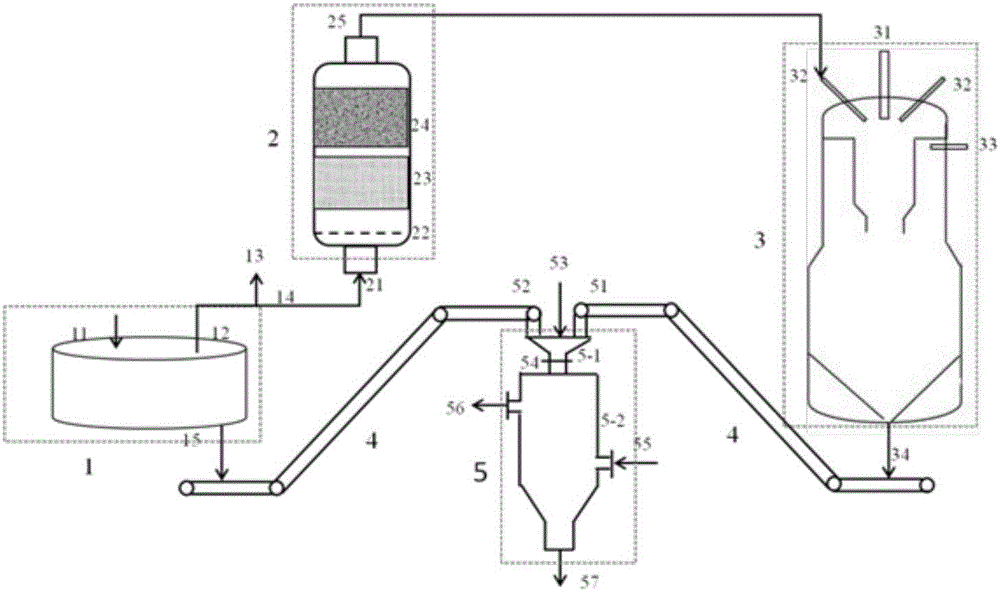

Embodiment 1

[0063] Utilizing the system of the present invention, the biomass whose length is less than 10 mm is sent into the non-heat carrier regenerative preheating furnace. Biomass is pyrolyzed in the preheating furnace to produce biomass coke and oil and gas products. The pyrolysis temperature is 600°C and the pyrolysis time is 50 minutes; the pyrolysis oil and gas are separated from oil and gas to obtain light tar and pyrolysis gas 1; light tar It is directly collected, purified and stored; the pyrolysis gas 1 is transported to the PSA absorber through a pipeline, and passes through a block of quicklime bed at 0.6Mpa to remove water and CO 2 , and pass through the solid filter bed for dust removal and purification to obtain pyrolysis gas 2; the pyrolysis gas 2 enters the hydrogenation gasifier through the nozzle, and is fully mixed with the coal powder sprayed into the coal powder nozzle, and is heated at 850°C and 2.0MPa The hydrogenation gasification reaction is carried out to obt...

Embodiment 2

[0065] This embodiment is the same as the system used in the above-mentioned embodiment 1, but the process conditions are different, as described below. The biomass with a length of less than 10mm is sent into the non-heat carrier regenerative preheating furnace. Biomass is pyrolyzed in the preheating furnace to produce biomass coke and oil and gas products. The pyrolysis temperature is 500°C and the pyrolysis time is 40 minutes; the pyrolysis oil and gas are separated from oil and gas to obtain light tar and pyrolysis gas 1; light tar It is directly collected, purified and stored; the pyrolysis gas 1 is transported to the PSA absorber through a pipeline, and passes through a block of quicklime bed at 1Mpa to remove water and CO 2 , and go through the solid filter bed for dust removal and purification to obtain pyrolysis gas 2; the pyrolysis gas 2 enters the hydrogenation gasifier through the nozzle, and is fully mixed with the coal powder injected by the coal powder nozzle, a...

Embodiment 3

[0067] This embodiment is the same as the system used in the above-mentioned embodiment 1, but the process conditions are different, as described below. The biomass with a length of less than 10mm is sent into the non-heat carrier regenerative preheating furnace. Biomass is pyrolyzed in the preheating furnace to produce biomass coke and oil and gas products. The pyrolysis temperature is 650°C and the pyrolysis time is 60 minutes; the pyrolysis oil and gas are separated from oil and gas to obtain light tar and pyrolysis gas 1; light tar It is directly collected, purified and stored; the pyrolysis gas 1 is transported to the PSA absorber through a pipeline, and passes through a block of quicklime bed at 0.4Mpa to remove water and CO 2 , and pass through the solid filter bed for dust removal and purification to obtain pyrolysis gas 2; the pyrolysis gas 2 enters the hydrogenation gasifier through the nozzle, and is fully mixed with the coal powder sprayed into the coal powder nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com