Patents

Literature

47results about How to "Eliminate steric hindrance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

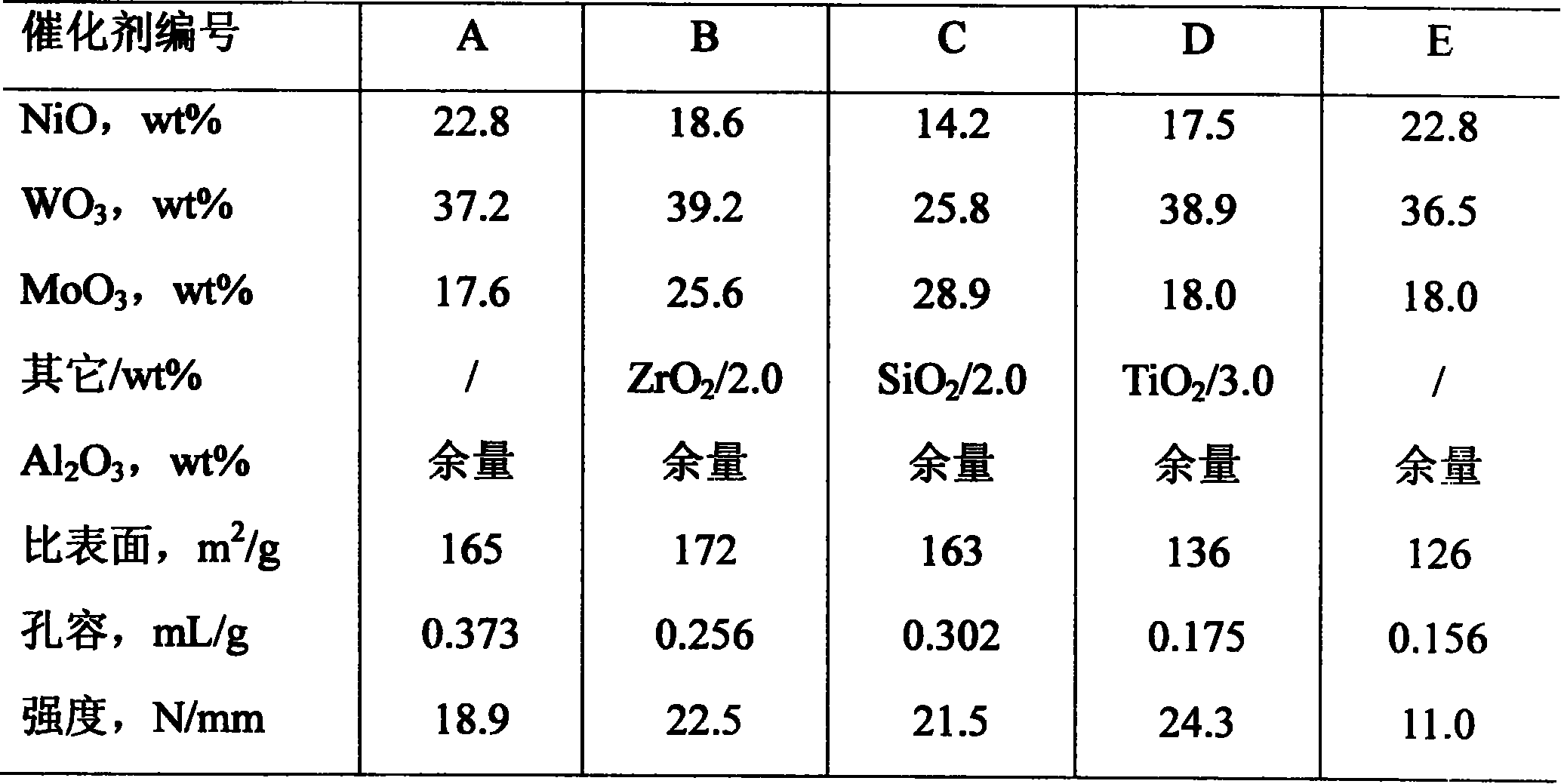

A catalyst composition and preparation method thereof

ActiveCN1951561AHigh activityIncrease contentMetal/metal-oxides/metal-hydroxide catalystsHydrogenMass ratio

The invention relates to a catalyst compound and relative preparation. Wherein, said compound comprises NixWyO2 compound oxide and MoO3, whose mass ratio is 1:10-10:1, and they are 40-100% of total mass. The inventive preparation comprises that using share deposition method to prepare the forward body of NixWyO2 compound oxide, to be mixed and beaten with MoO3; filtering, shaping and activating. The invention can adjust the cooperation between different metals, to obtain high property, with simple method and low metal loss. And the inventive catalyst is used in deep hydrogen process of hydrocarbons material.

Owner:CHINA PETROLEUM & CHEM CORP +1

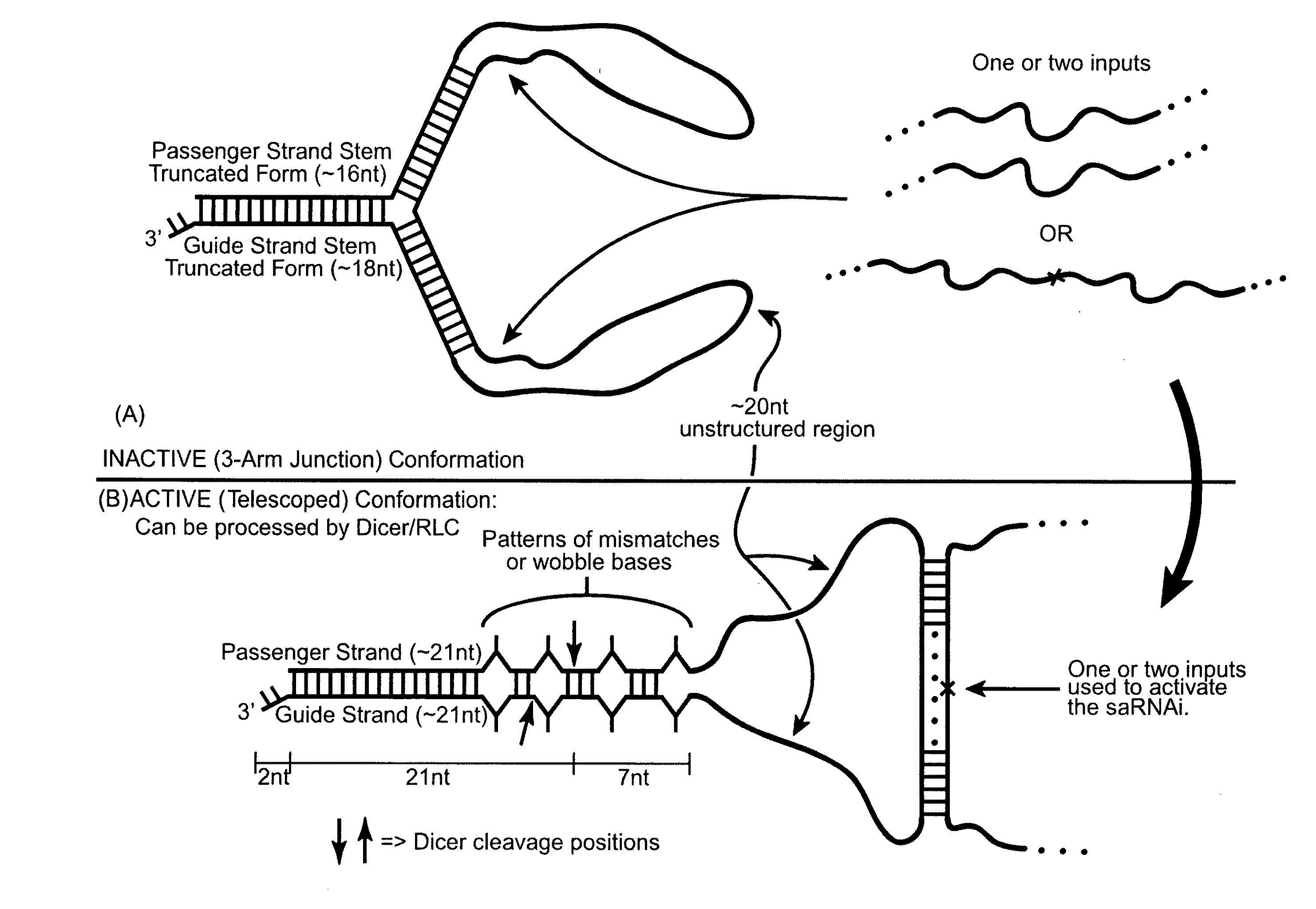

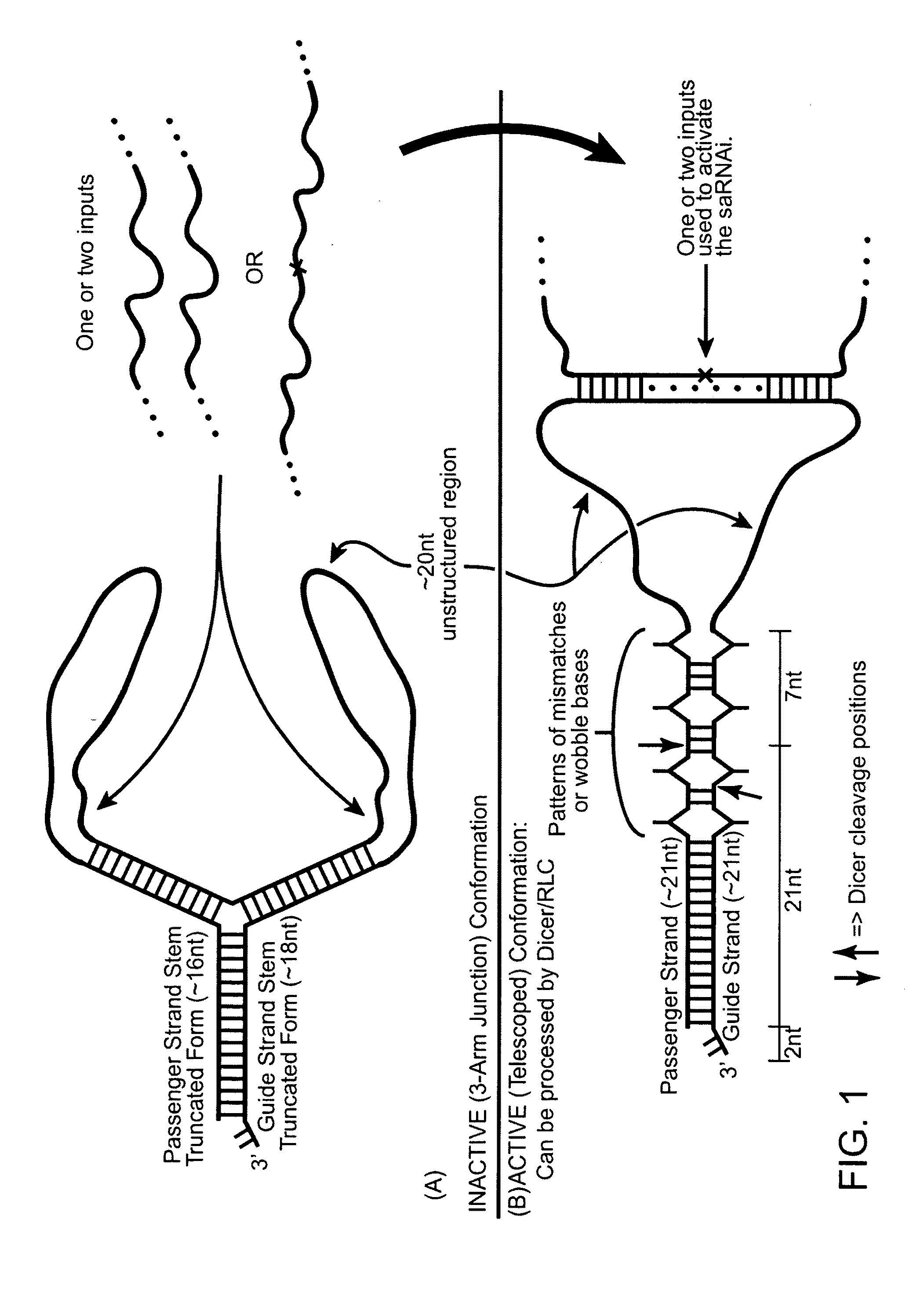

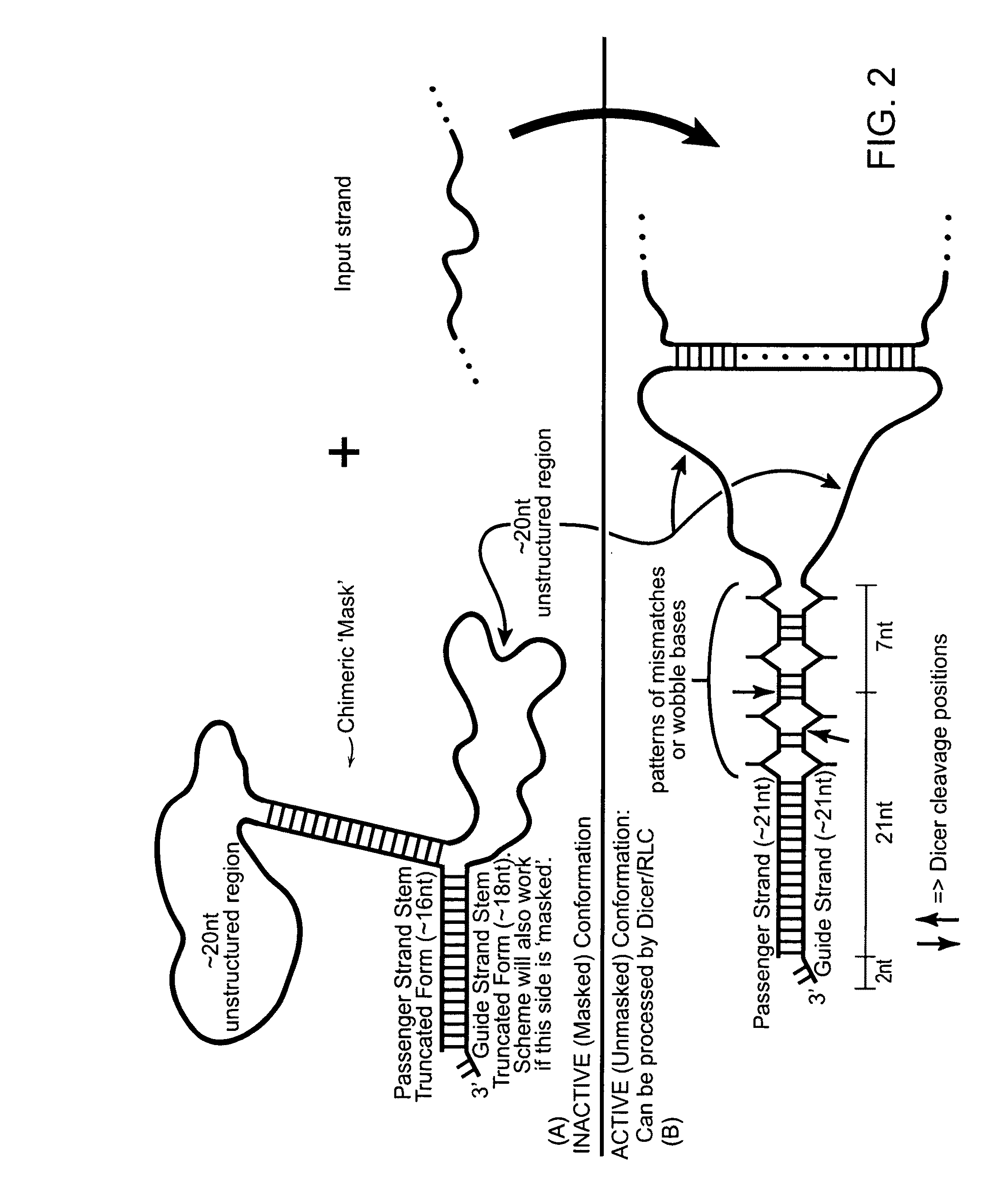

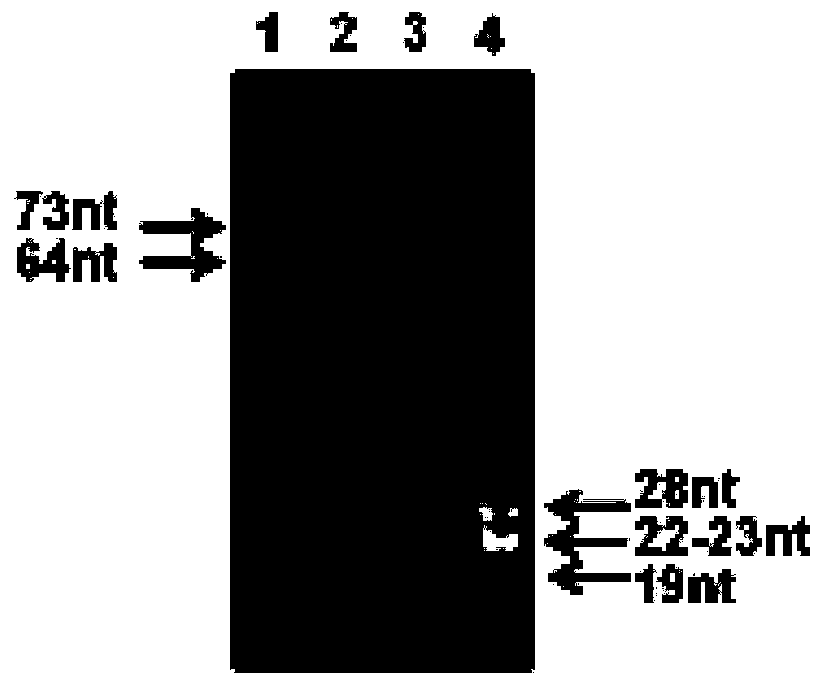

Signal activated RNA interference

ActiveUS20090234109A1Eliminate steric hindranceInhibits the degradation of the blocking sequenceSugar derivativesScreening processHomopolynucleotideDicer

The invention provides compositions and methods for signal activated RNA interference (saRNAi), preferably in vivo. The invention provides polynucleotides that switches between an inactive form and an active form upon covalent or non-covalent interaction with one or more specific chemical signals, such as disease-specific mRNA, miRNA, or other cellular RNA products with sequences that characterize diseased states of the cell. The interaction between the subject polynucleotides and the signals is preferably mediated by hybridization, which exposes, facilitates the formation, and / or allows the formation of a substrate that can be processed by proteins of the RNAi pathway (such as Dicer). The input and output of multiple different polynucleotides of the invention can form an in vivo signaling network. In addition, the multiple input signals can be integrated to modulate the activity of the subject polynucleotides.

Owner:CALIFORNIA INST OF TECH

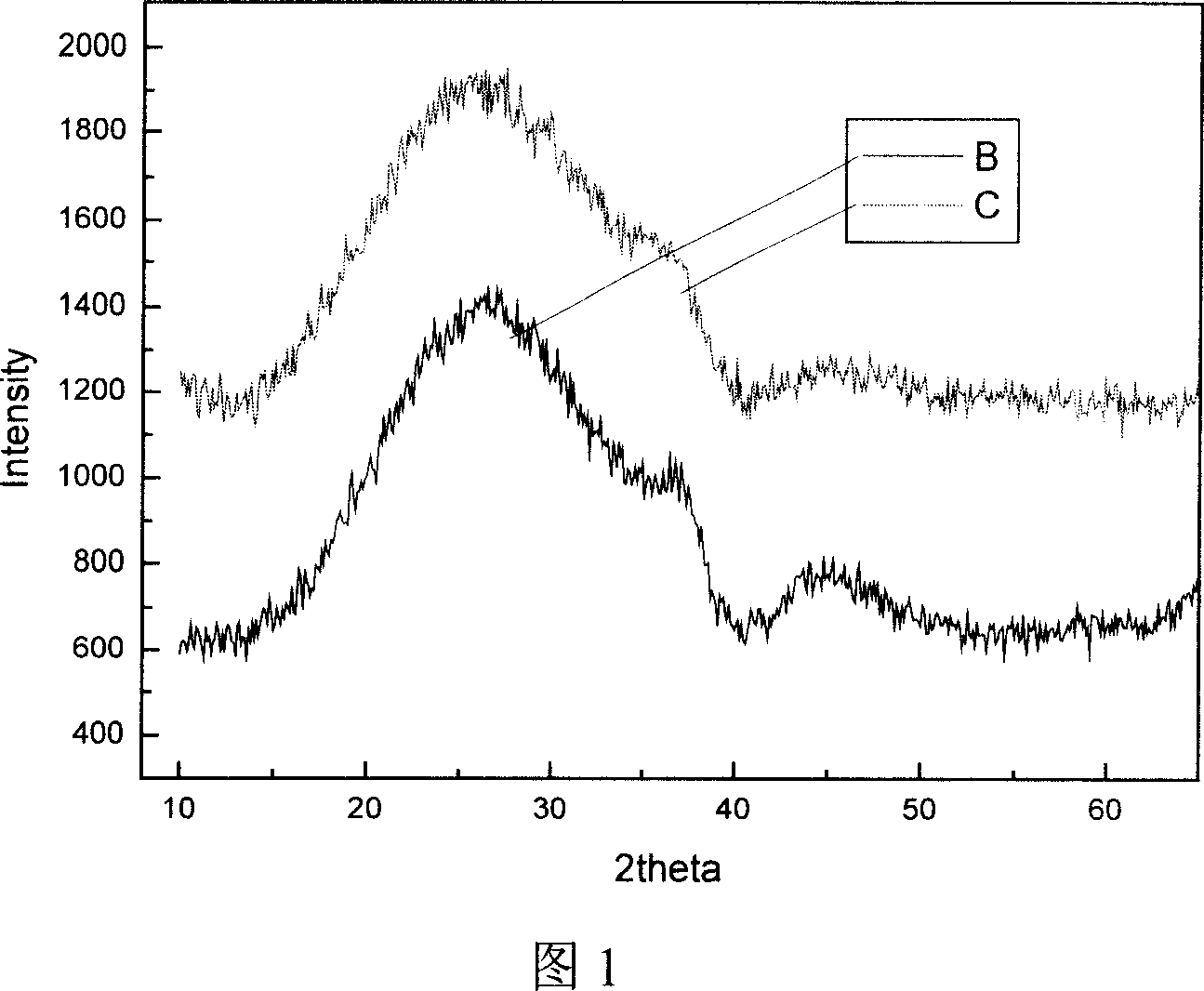

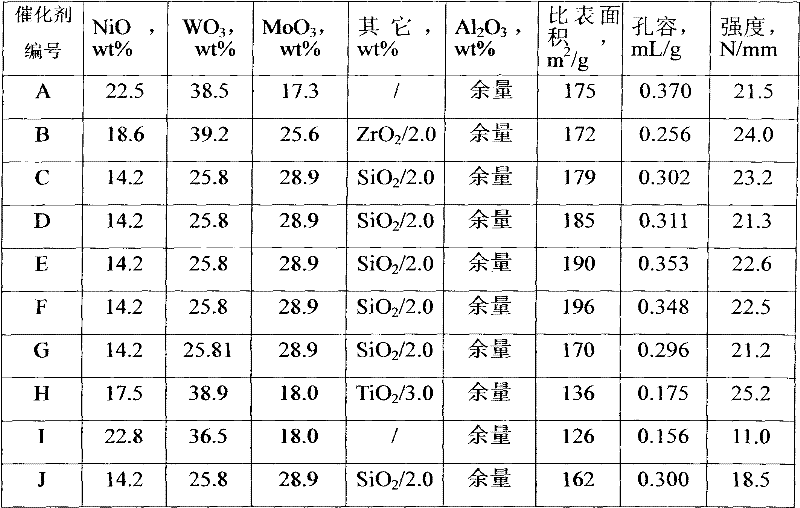

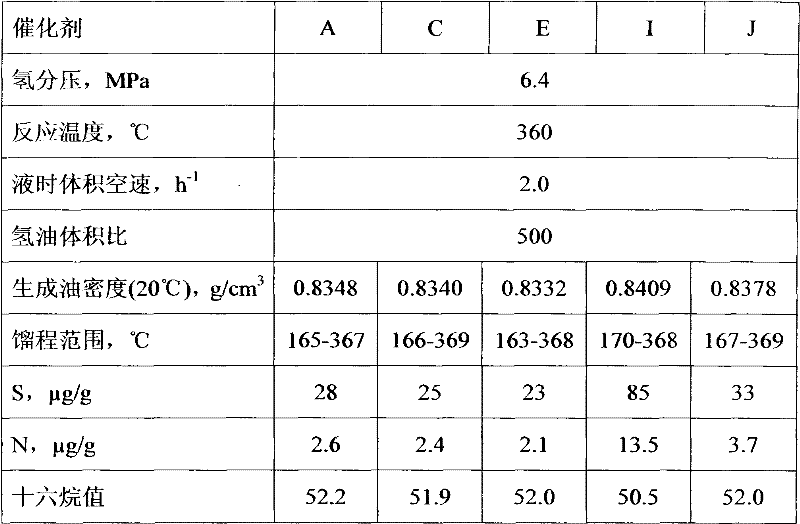

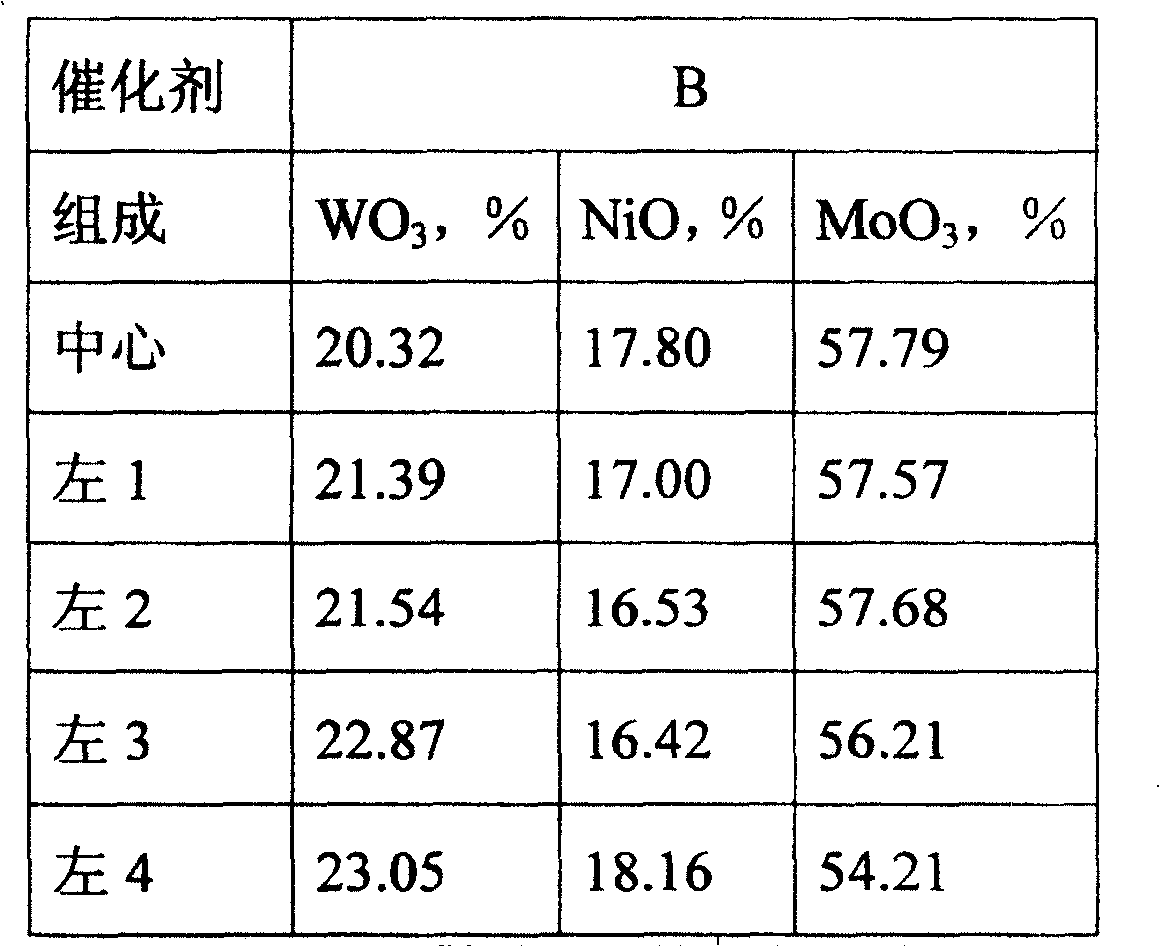

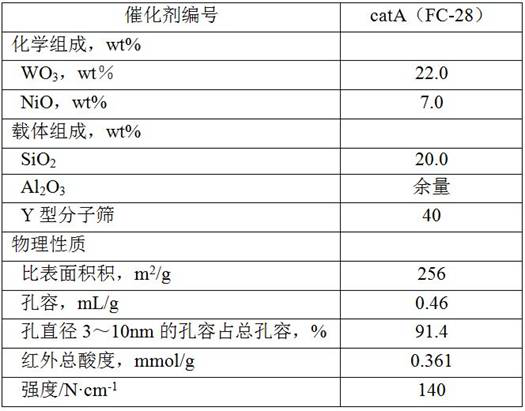

Preparation of hydrogenation catalyst

ActiveCN101172261AHigh activityIncrease contentCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsChemistryComposite oxide

The invention relates to a preparation method of a catalyst composition. The precursor of NixWyOz composite oxide is generated by co-precipitation method, and then mixed with MoO3, filtered, shaped and activated to become the final catalyst. The method for generating the precursor of the NixWyOz composite oxide by the co-precipitation method is: preparing the salt mixed solution A containing active metal Ni, W components and additives according to the ratio of catalyst components. Sodium metaaluminate solution B is prepared according to the proportion of catalyst components. Solution B and solution A flow into a reaction tank equipped with clean water to form a gel, and a gel-like mixture is formed, which is the precursor of the composite oxide NixWyOz. The catalyst metal prepared by the method of the invention is evenly dispersed and has high performance, especially higher activity for the process of deeply removing impurities of hydrocarbons. Moreover, the method of the invention is simple and convenient, and the metal loss rate is low. The method of the invention is mainly used for preparing bulk phase catalysts with higher metal content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing catalyst composition

ActiveCN1951558AHigh activityIncrease contentMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsSlurryDeposition process

The invention relates to a method for preparing catalyst compound. Wherein, it uses deposition method to generate the forward body of NixWyOz compound oxide; then mixing and beating with MoO3, filtering, shaping and activating to obtain the final catalyst. The deposition process comprises that adding the salt mixture with active metals Ni and W into the reaction pot, combining it with alkali deposit agent, to be put into reaction pot to form paste; the pH value of reaction pot is 7.0-9.0; obtaining the gel mixture as the forward body. The invention can improve the catalyst property, with high metal content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparation of hydrogenation catalyst composition

ActiveCN1952054AHigh activityIncrease contentRefining to eliminate hetero atomsLoss rateSal ammoniac

The invention relates to the preparing method of a catalyst compound. The invention adopts coprecipitation to produce compound oxide predecessor, then pulp the predecessor and MoO3. After mixing the pulp, filtering, shaping and activating, the producers can get the catalyst. The producing procedure of NixWyOz includes the following steps: preparing the mixture that contains Ni and W, adding strong aqua to get A solution; preparing the mixture B that contains the added sunstances, mixing mixture B with strong aqua to get the gel and adding A to the gel; heating the material to vaporize the ammonia until the ph value reaches 7.5-9.0. The metal in the catalyst spreads uniformly and the volume of the bore is very large, so the catalyst can process heavy materials. The activity during the deep de-impurity process is even higher. The invention is characterized by simple method and low metal loss rate and it's mainly used to produce catalysts with higher metal content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for catalytic oxidization of volatile organic compound, as well as preparation method of catalyst

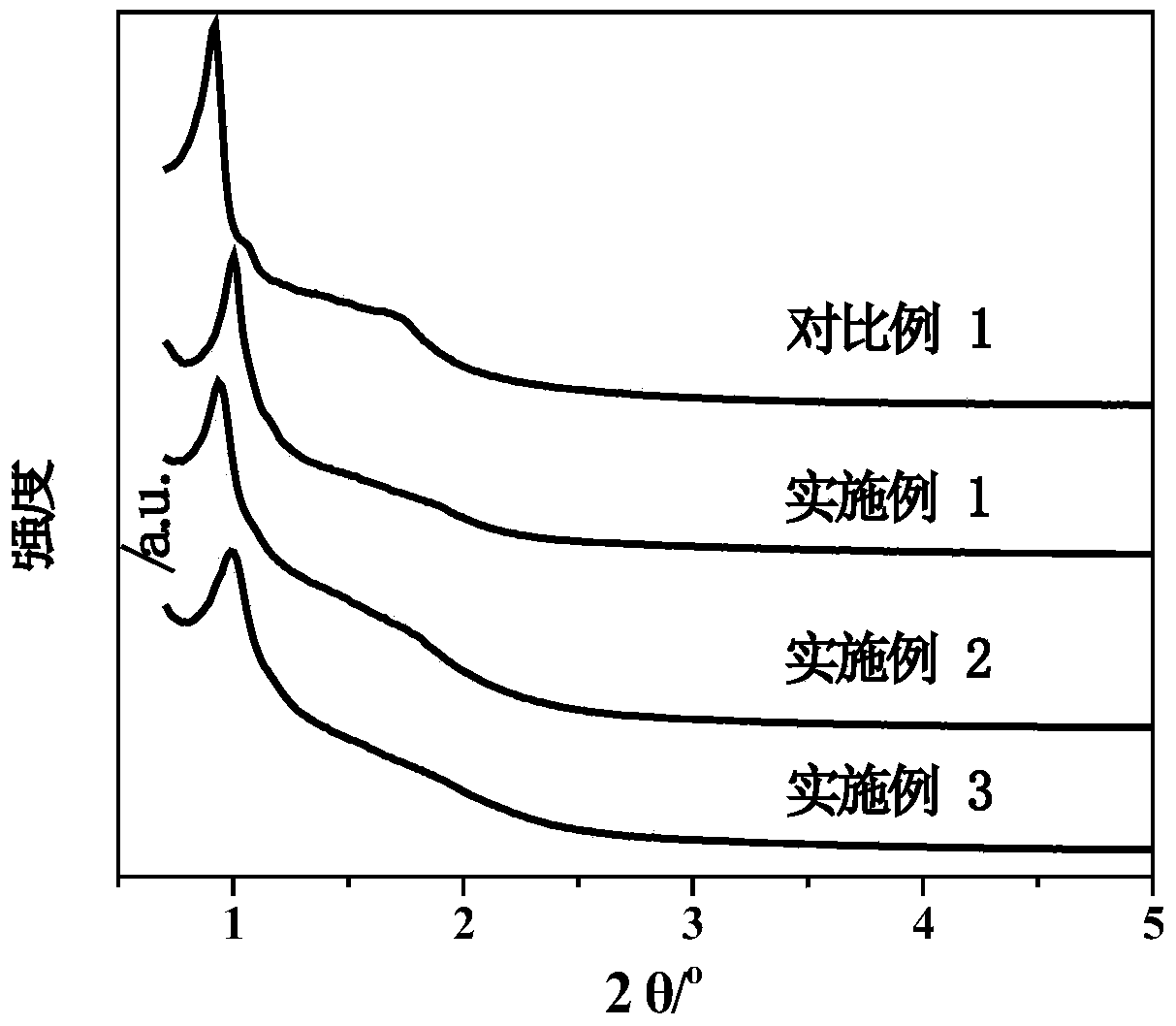

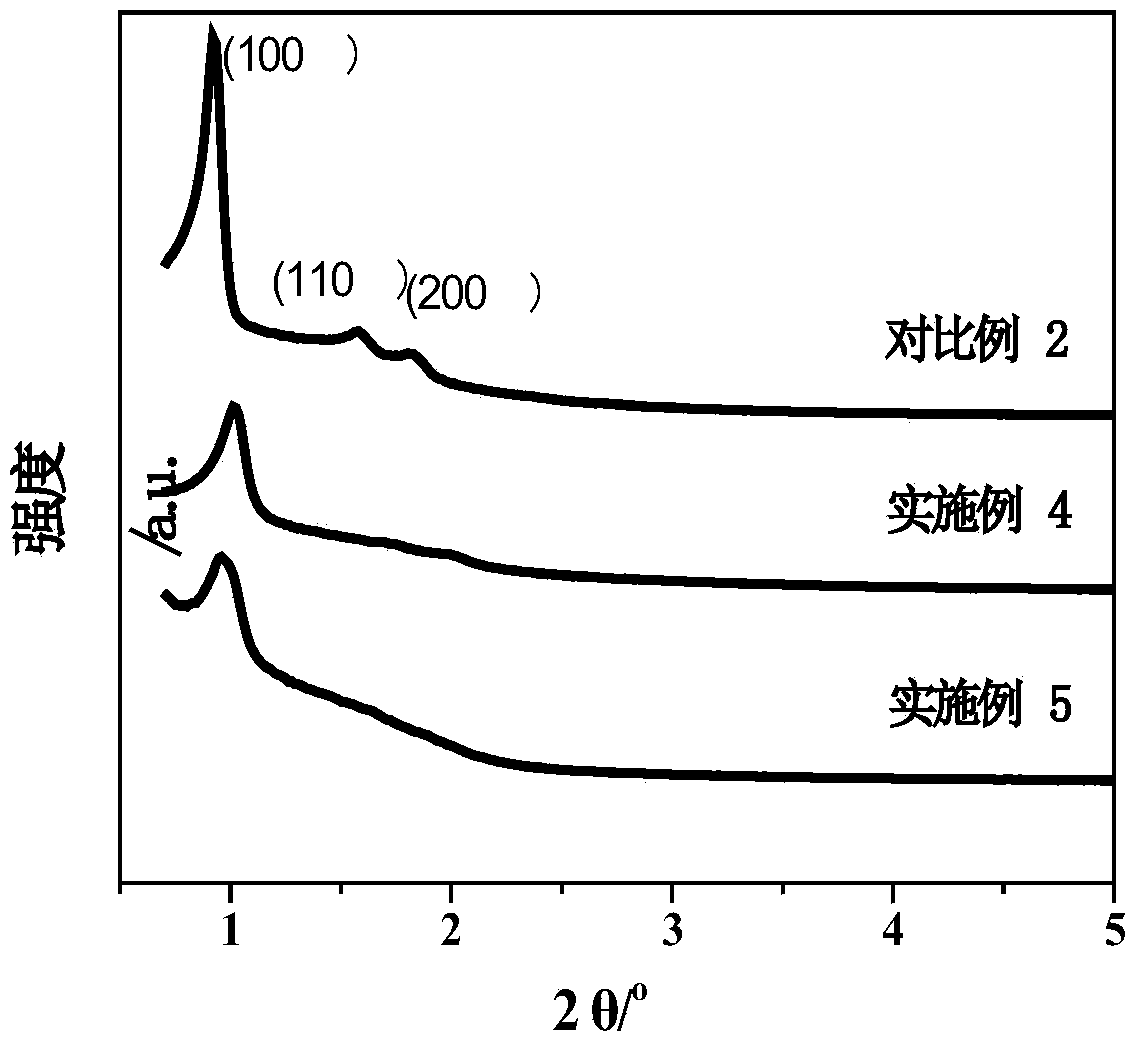

ActiveCN104174425AGood dispersionReduce resistanceMolecular sieve catalystsDispersed particle separationBenzeneMolecular sieve

The invention provides a catalyst for catalytic oxidization of a volatile organic compound, as well as a preparation method of the catalyst. An active component of the catalyst is Pd or Pt, a carrier is a hierarchical porous SBA-15 or KIT-6 and other molecular sieves with a macroporous-mesoporous structure. The carrier is prepared by adopting a soft-hard template method, and the active component is loaded on the carrier by adopting a sol-gel method or a steeping method. The catalyst has a large specific surface area, an orderly hierarchical porous structure, and high catalytic oxidization activity on volatile organic matters such as p-xylene, toluene and benzene at high space velocity.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

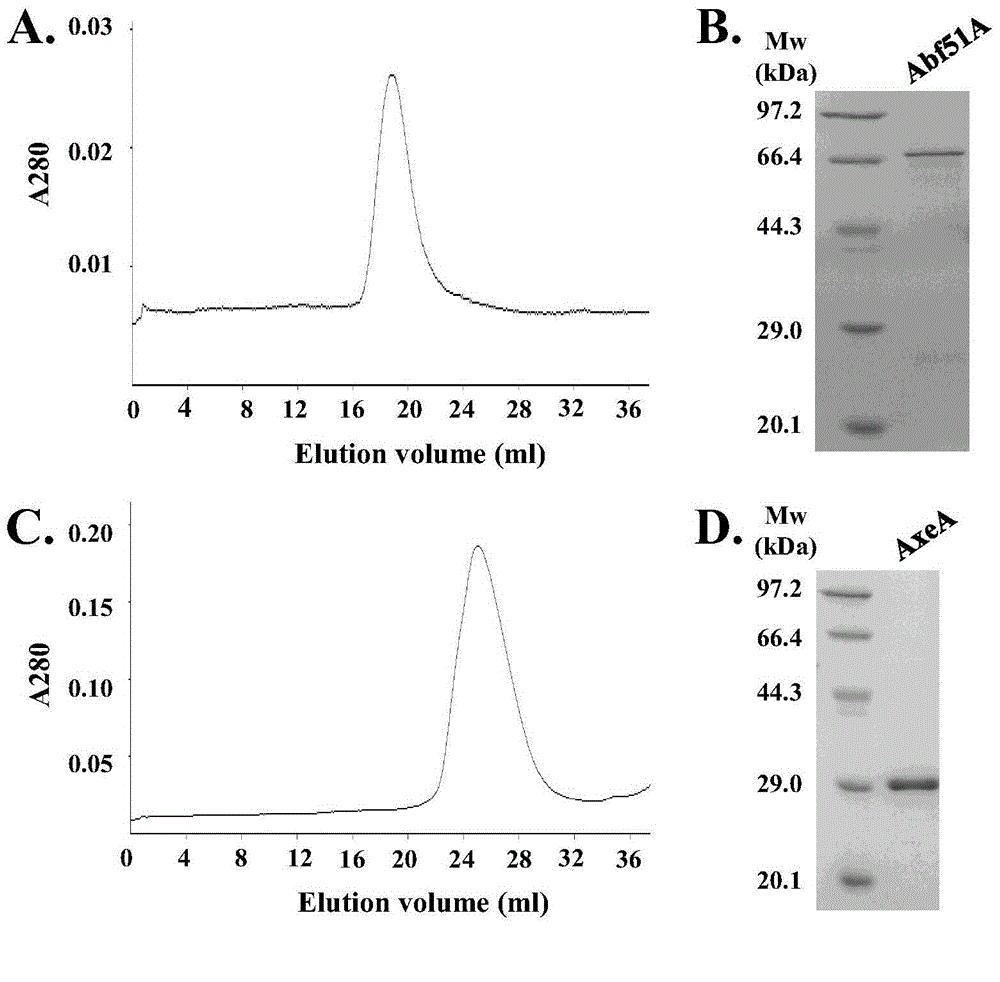

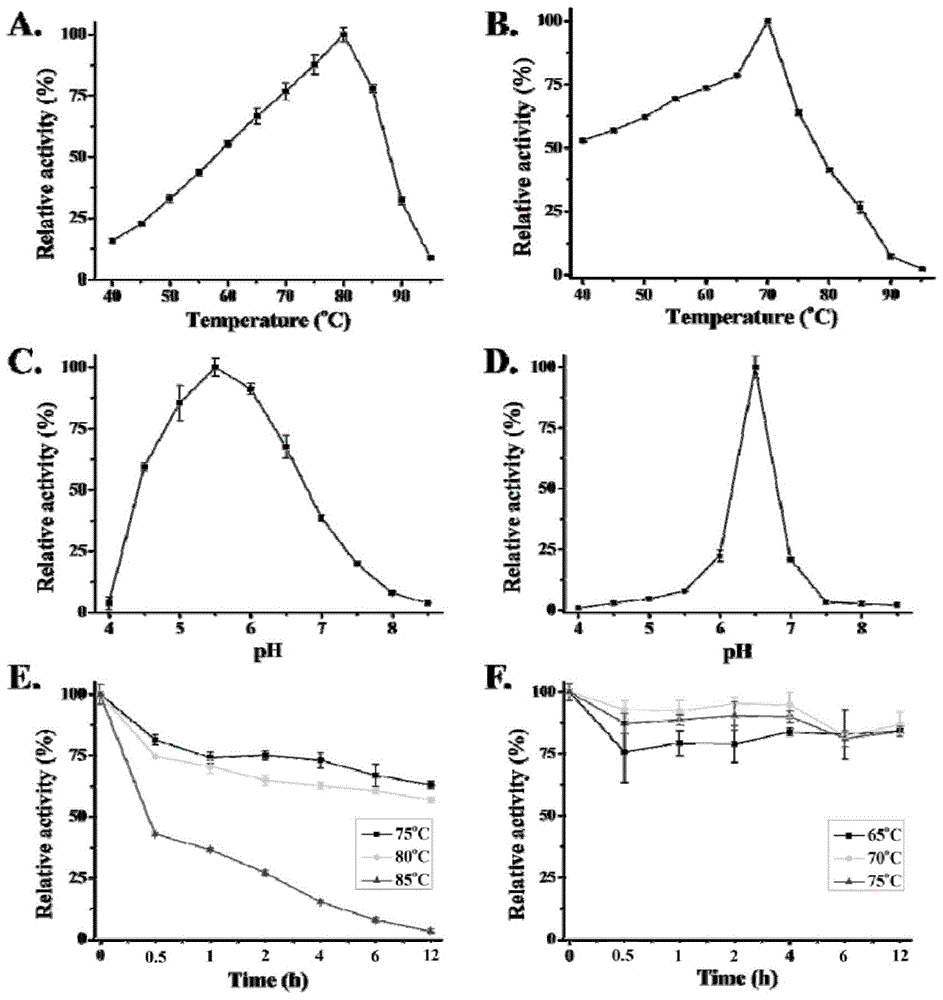

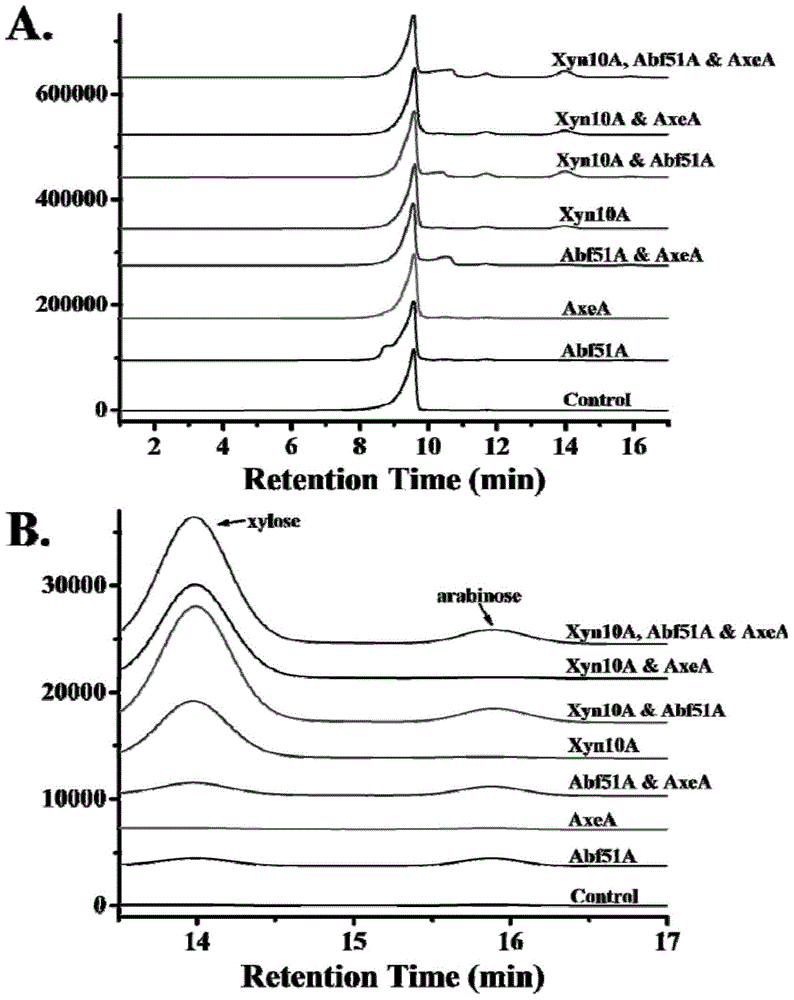

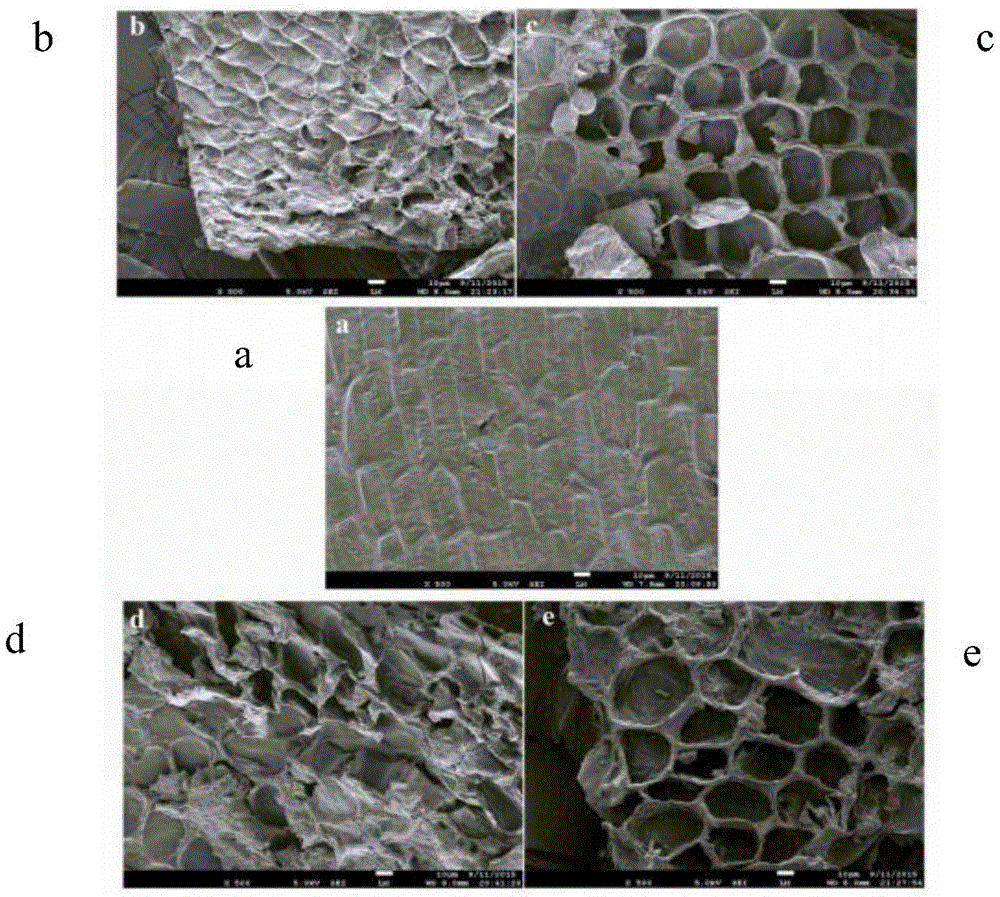

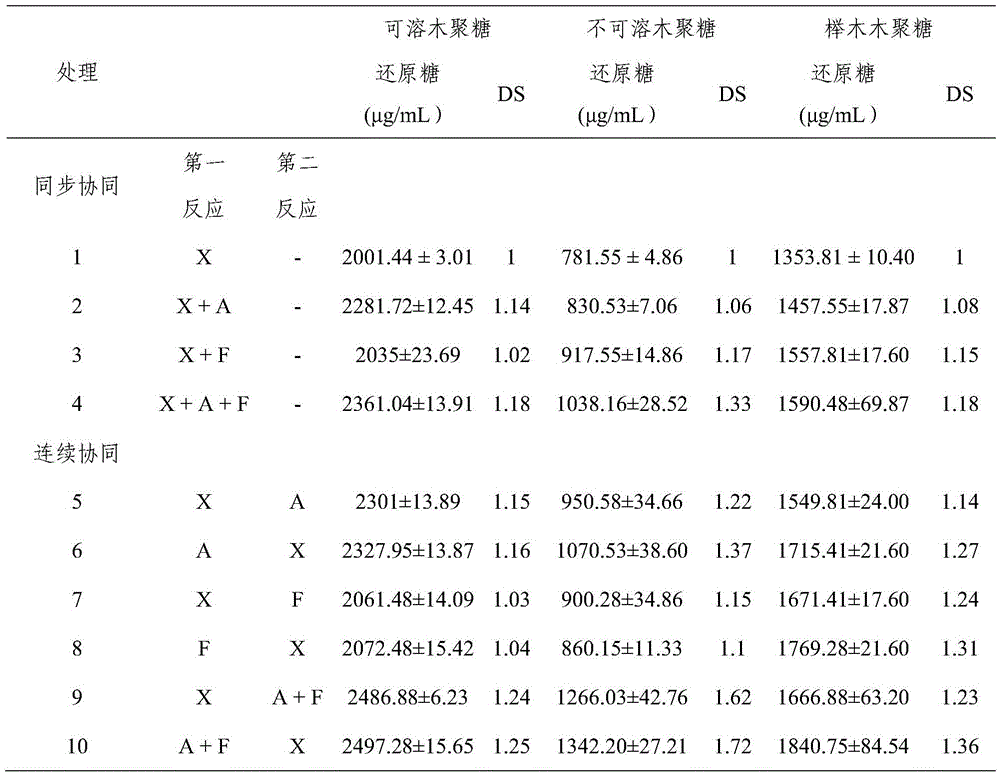

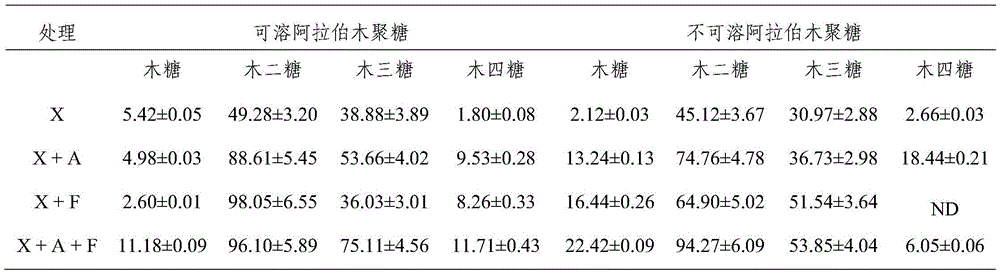

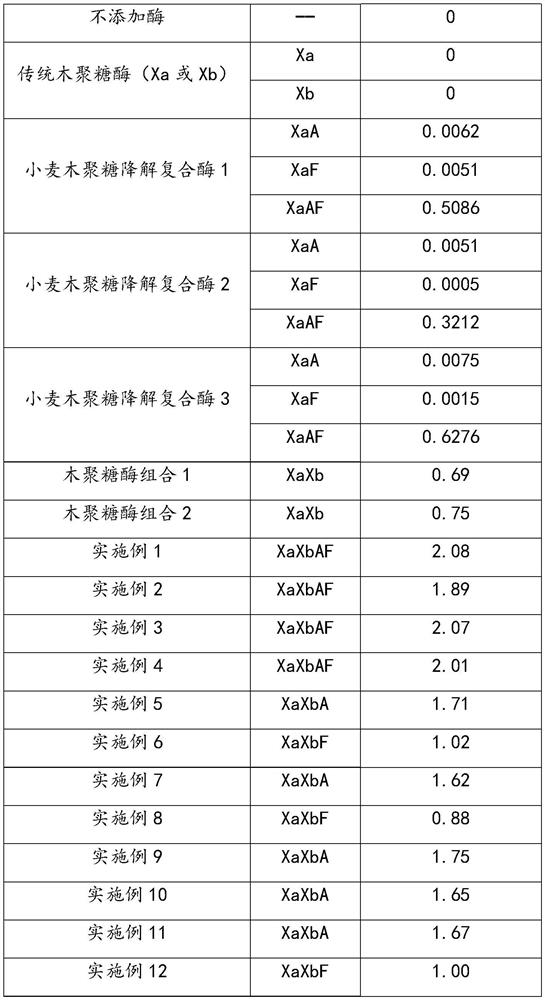

A high-temperature alpha-L-arabinfuranosidease gene, a high-temperature acetylxylan esterase gene, and protein expression and applications of the genes

InactiveCN105734069AImprove thermal stabilityPromote degradationBacteriaHydrolasesCelluloseSide chain

The invention provides a high-temperature alpha-L-arabinfuranosidease gene abf51A and a high-temperature acetylxylan esterase gene axeA which are derived from caldicellulosiruptor lactoaceticus 6A, and protein expression and applications of the genes. High-temperature alpha-L-arabinfuranosidease abf51A and high-temperature acetylxylan esterase axeA are advantaged by high optimum reaction temperatures, good thermal stability, and the like, and can effectively degrade natural xylan side chains at 65-85 DEG C with pH being 4.5-6.5 to produce arabinose, acetic acid and a small amount of xylose. The two enzymes can effectively eliminate steric hindrance of side chains to xylanase, improve biodegradability of the lignocellulose resource, can be widely used as novel enzyme preparations for feed, food, energy, and other fields, and have potential industrial application value.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation process for hydrogenation catalyst composition

ActiveCN1952057AHigh activityIncrease contentRefining to eliminate hetero atomsCoprecipitationAlkane

The invention relates to the preparing method of a catalyst compound. The invention adopts coprecipitation to produce compound oxide predecessor, then pulp the predecessor and MoO3. After mixing the pulp, filtering, shaping and activating, the producers can get the catalyst. The producing procedure of NixWyOz includes the following steps: preparing the mixture that contains Ni and W, adding strong aqua to get A solution; preparing the mixture B that contains the added sunstances, mix mixture B with strong aqua to get the gel and add A to the gel; heating the material to vaporize the ammonia until the pH value reaches 7.0-9.0. The metal in the catalyst spreads uniformly. It has high using efficiency, especially in the process of deep de-impurity process of alkanes. The invention is characterized by simple method and low metal loss rate and it's mainly used to produce catalysts with higher metal content.

Owner:CHINA PETROLEUM & CHEM CORP +1

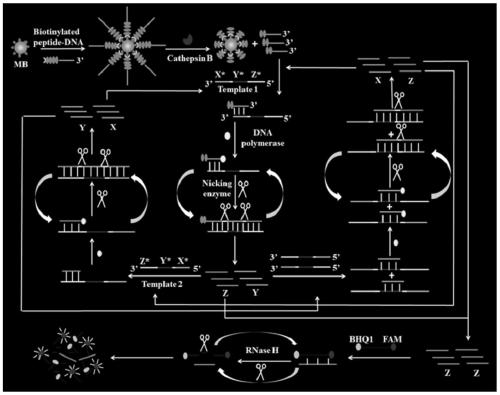

Biosensor for detecting cathepsin B as well as detection method and application thereof

ActiveCN111172235AEnables ultra-sensitive detectionHigh amplification efficiencyMicrobiological testing/measurementBiological material analysisCathepsin BA-DNA

The invention provides a biosensor for detecting cathepsin B as well as a detection method and application thereof, and belongs to the technical field of detection analysis. The biosensor at least comprises a polypeptide-DNA conjugate, a DNA template 1 and a DNA template 2. First primer DNA containing an amino acid residue is converted into new primer DNA containing no amino acid residue, the steric hinerance effect in a nucleic acid amplification process can be completely eliminated, and the amplification reaction efficiency can be improved. Meanwhile, proceeding of multiple chain replacementreactions and the circulating digestion function of ribonuclease H can further amplify a fluorescence signal, so that ultra-sensitive detection of the activity of cathepsin B can be realized, and thebiosensor has good practical application values.

Owner:SHANDONG NORMAL UNIV

Wheat based diet specific xylan degradation compound enzyme preparation and preparation method and application thereof

InactiveCN105462948AGenerate morePromote value-addedAnimal feeding stuffGlycosylasesLactobacillusXylan degradation

The invention relates to a wheat based diet specific xylan degradation compound enzyme preparation. The active component of the wheat based diet specific xylan degradation compound enzyme preparation comprises xylanase and arabinfuranosidease and / or ferulic acid esterase. The invention aims at preparing the wheat based diet specific araboxylan degradation compound enzyme preparation according to the structural features of the wheat araboxylan, and the utilization effect of poultry to wheat is targetedly improved. By means of the specific xylan degradation compound enzyme preparation, the utilization effect of the wheat is improved, proliferation of beneficial bacteria such as intestinal lactic acid bacteria and the like is further facilitated, intestinal health is achieved, and the production performance of the poultry is greatly improved.

Owner:CHINA AGRI UNIV

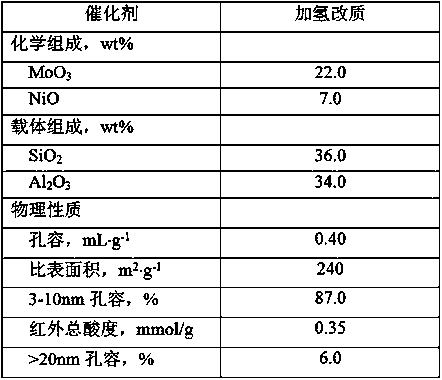

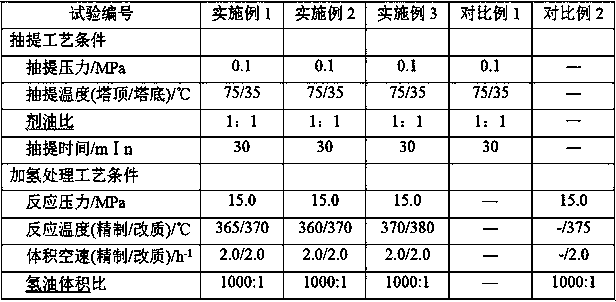

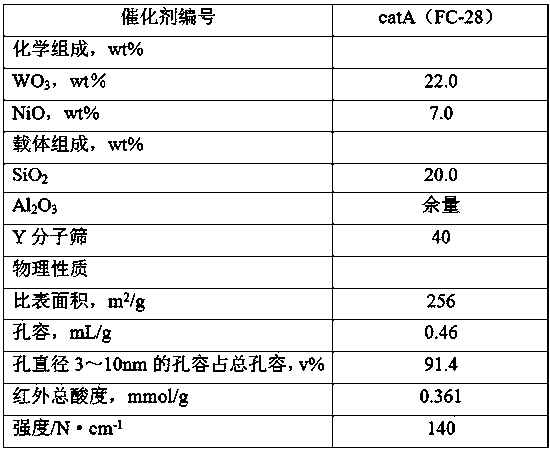

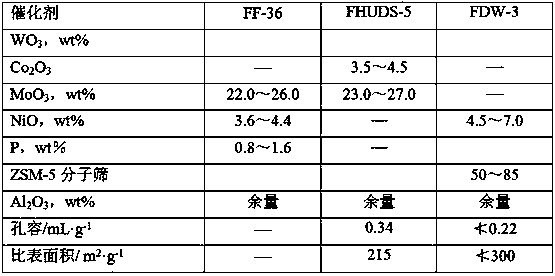

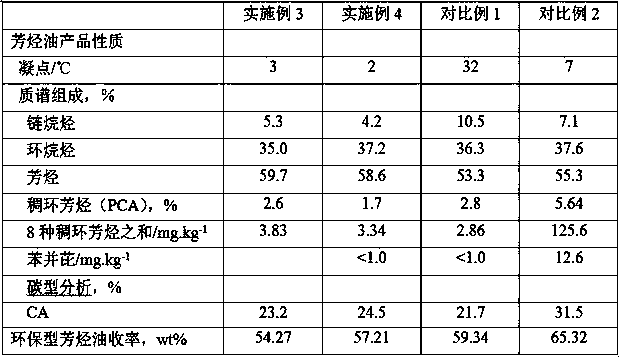

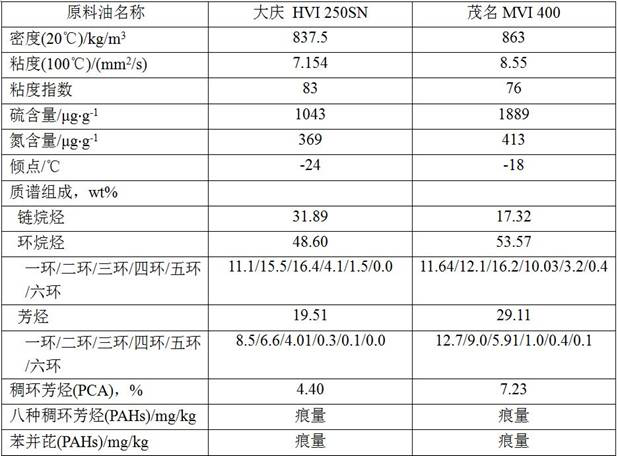

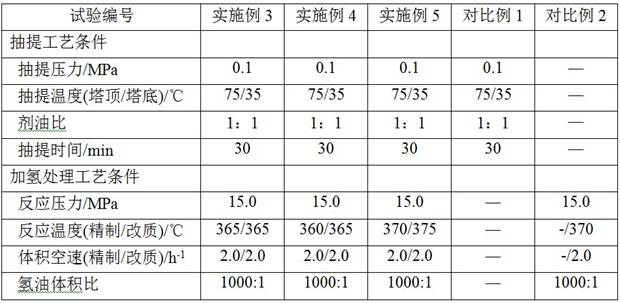

Combined method for producing high-quality lubricant base oil and environment-friendly aromatic hydrocarbon oil

ActiveCN111378499AEliminate steric hindranceImprove denitrification effectTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonEnvironmental engineering

The invention discloses a combined method for producing lubricant base oil and environment-friendly aromatic hydrocarbon oil. API I lubricant base oil with very low polycyclic aromatic hydrocarbon content produced by three old processes is subjected to solvent extraction, and the extraction depth is controlled, so that aromatic hydrocarbon in raffinate oil is further reduced; then through hydrofining and hydro-upgrading, the color and stability are improved, the viscosity index is increased, and the indexes of API III type lubricant base oil are reached; meanwhile, the aromatic hydrocarbon isenriched into the extract oil, so that the content of polycyclic aromatic hydrocarbon (3.0%, aromatic hydrocarbon content) in the extract oil is 20%, and the excellent rubber filling oil for the tireindustry is obtained. According to the method disclosed by the invention, two products with high additional values can be obtained at the same time by modifying the base oil I; and the method has theadvantages of high target product yield, low operation cost and no waste treatment in the processing process.

Owner:CHINA PETROLEUM & CHEM CORP +1

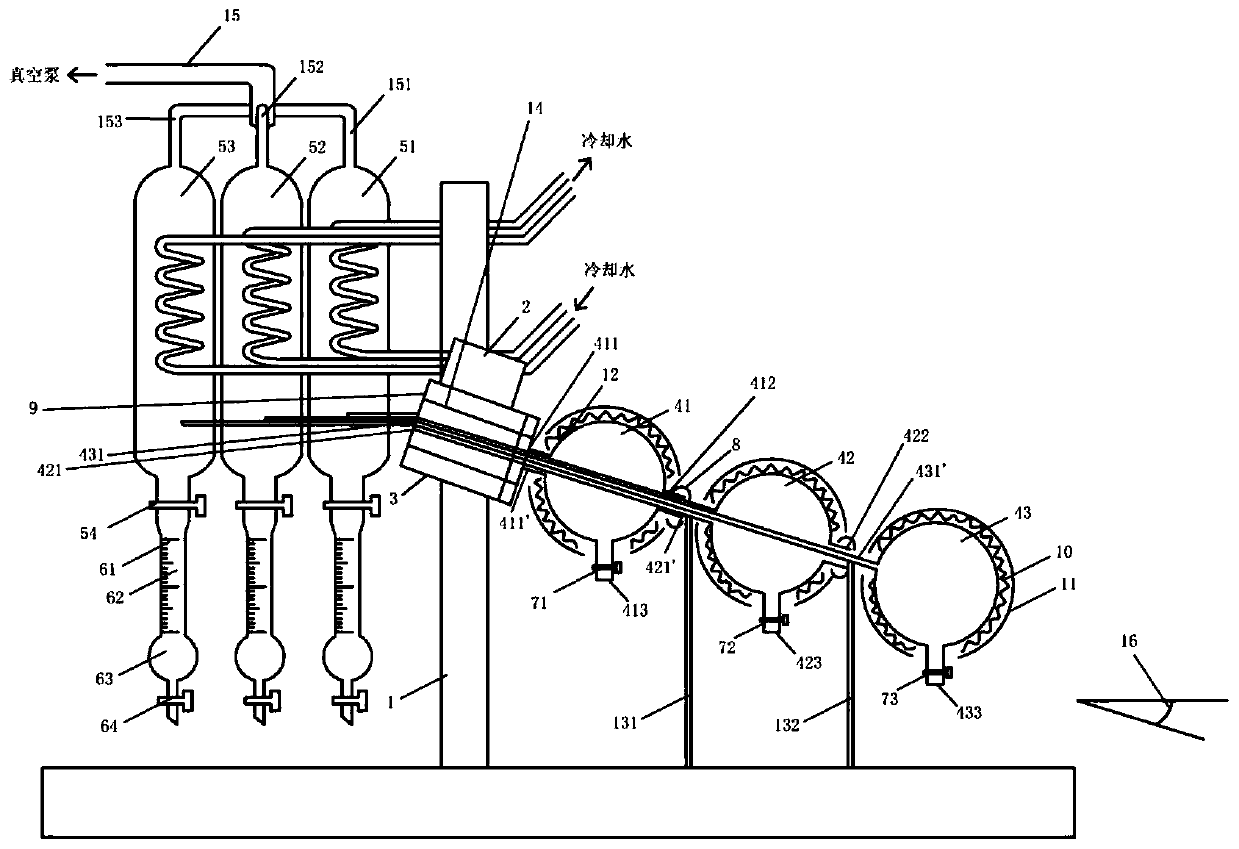

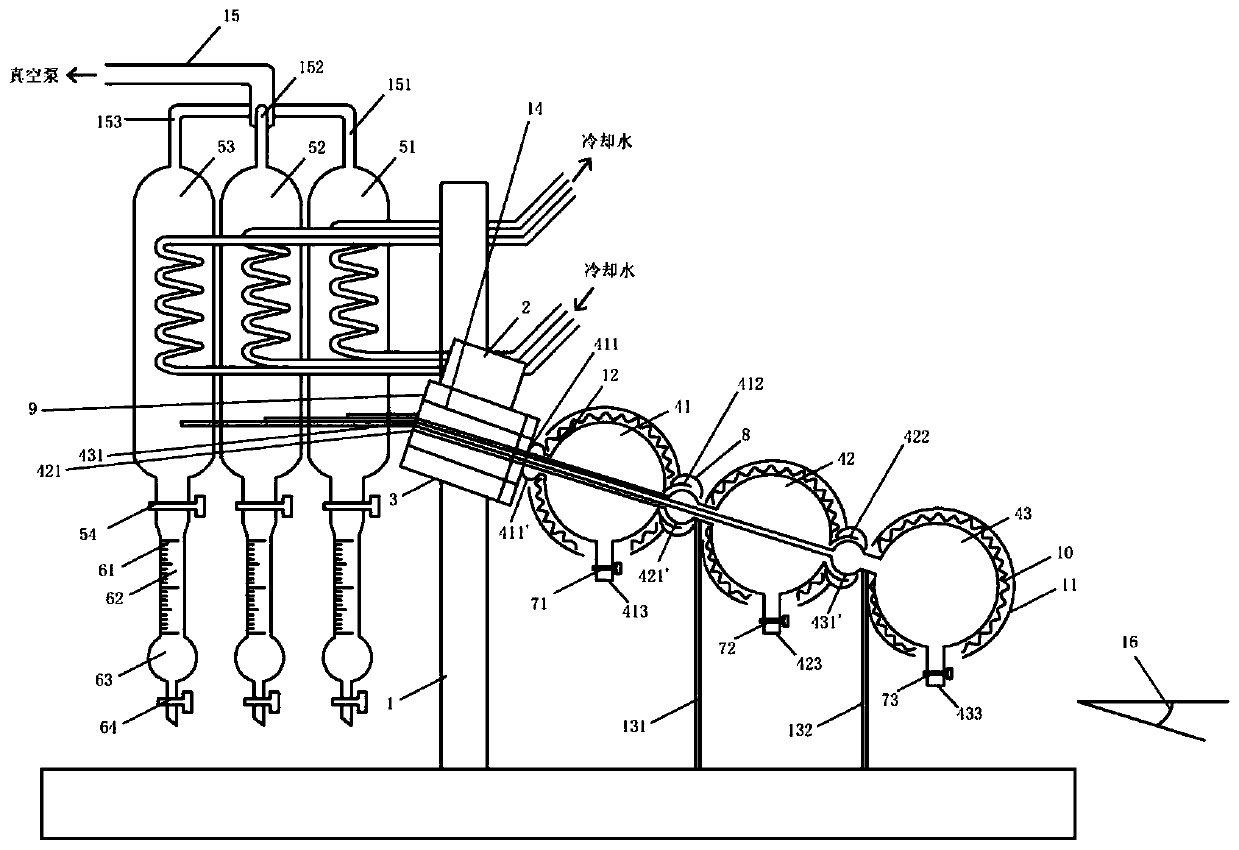

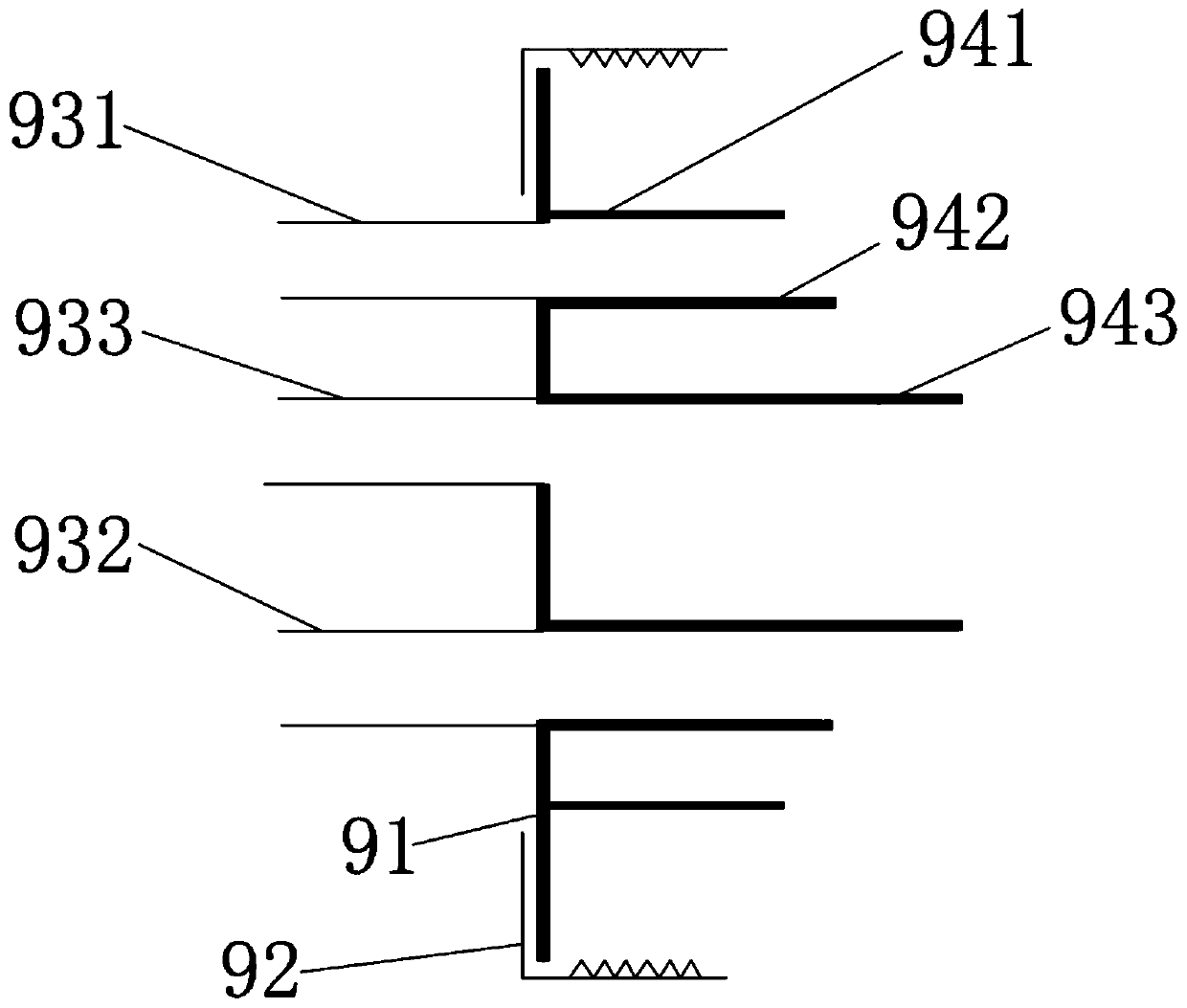

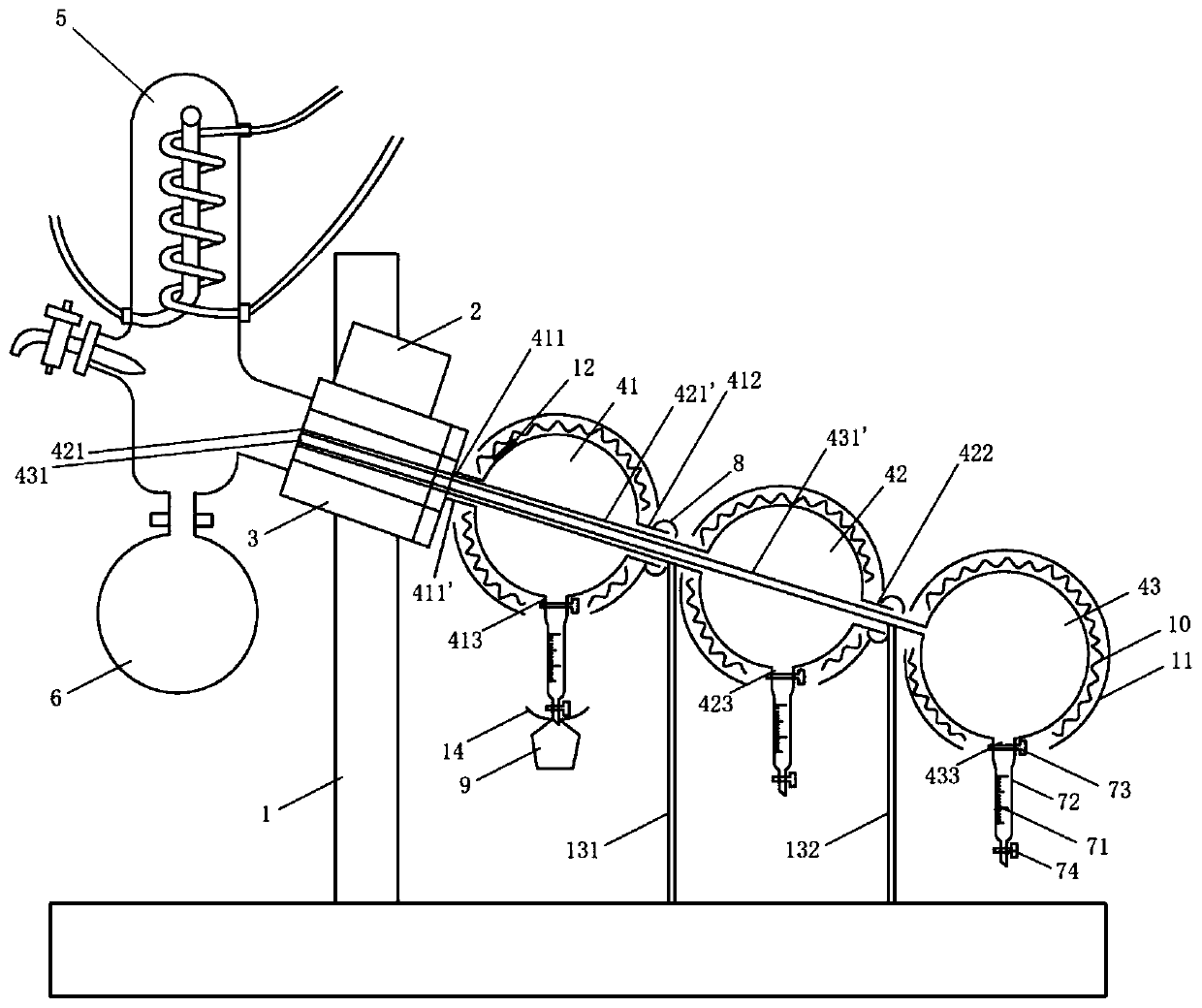

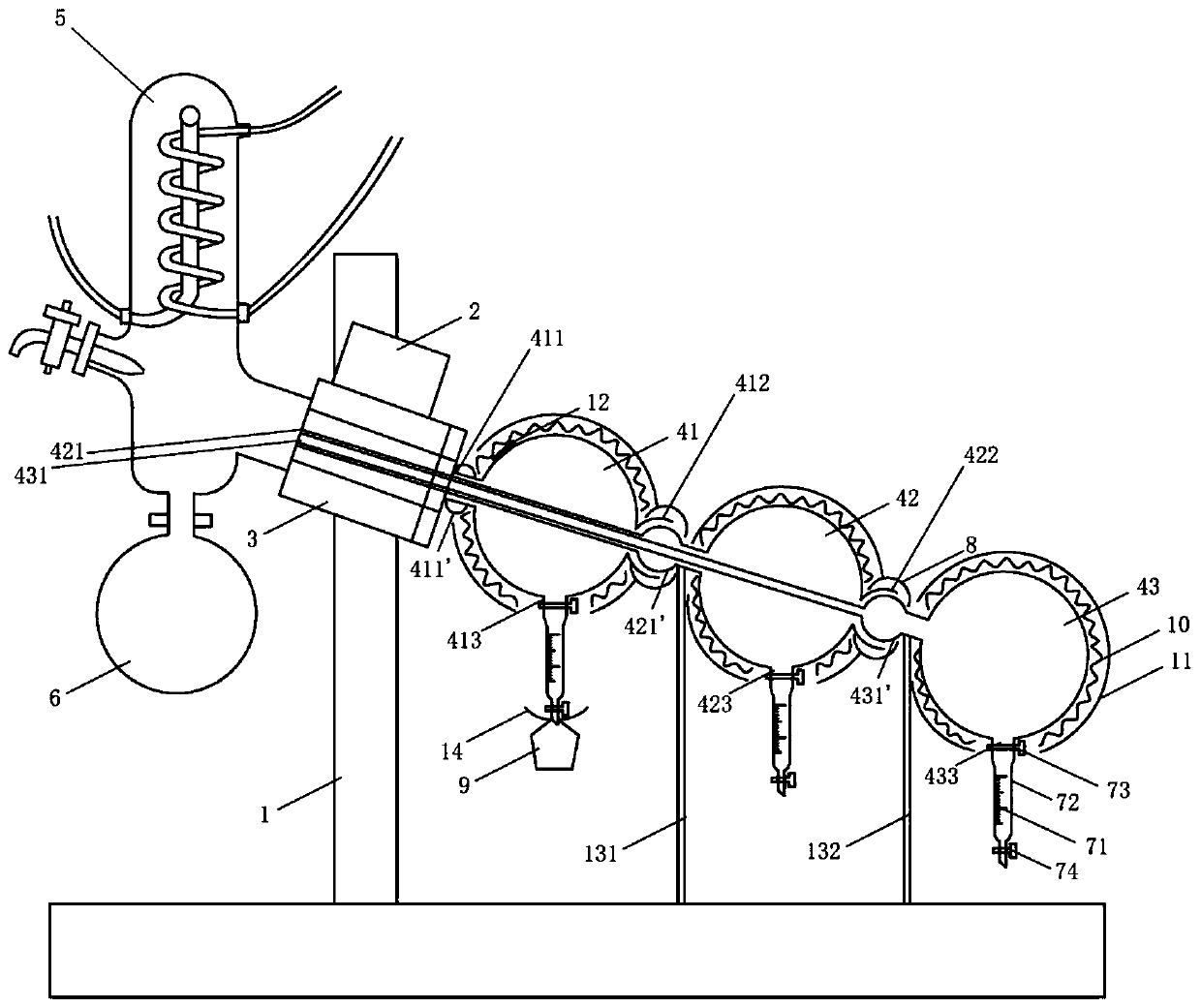

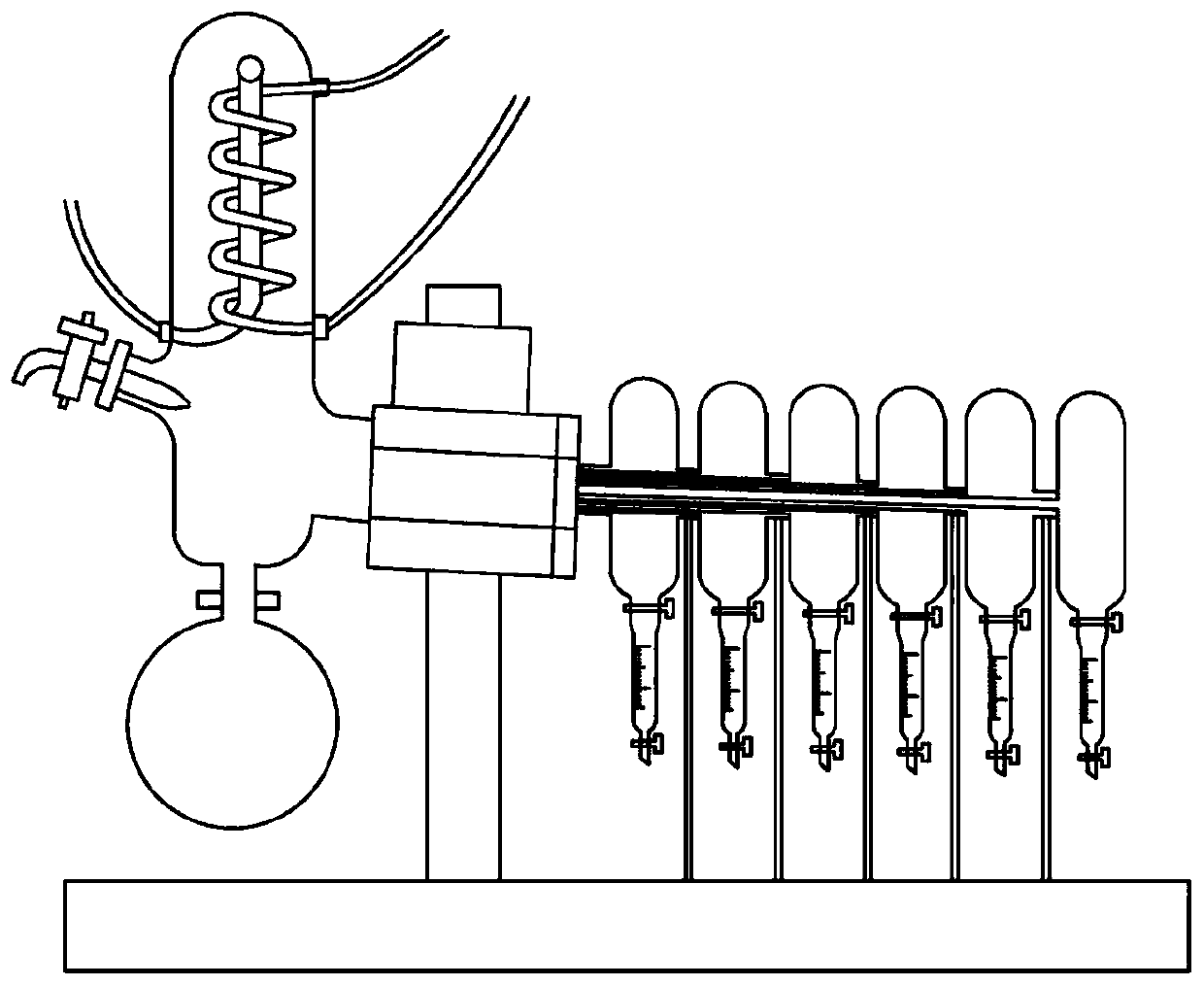

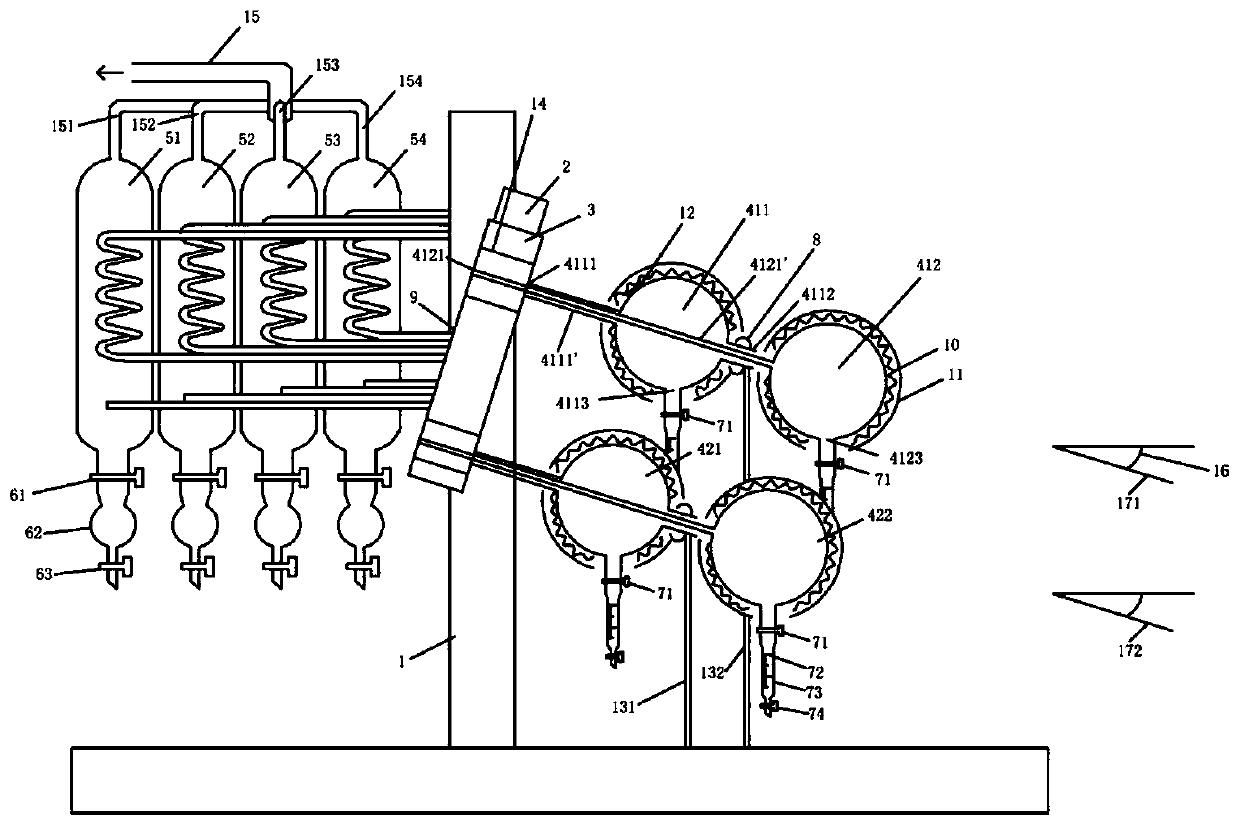

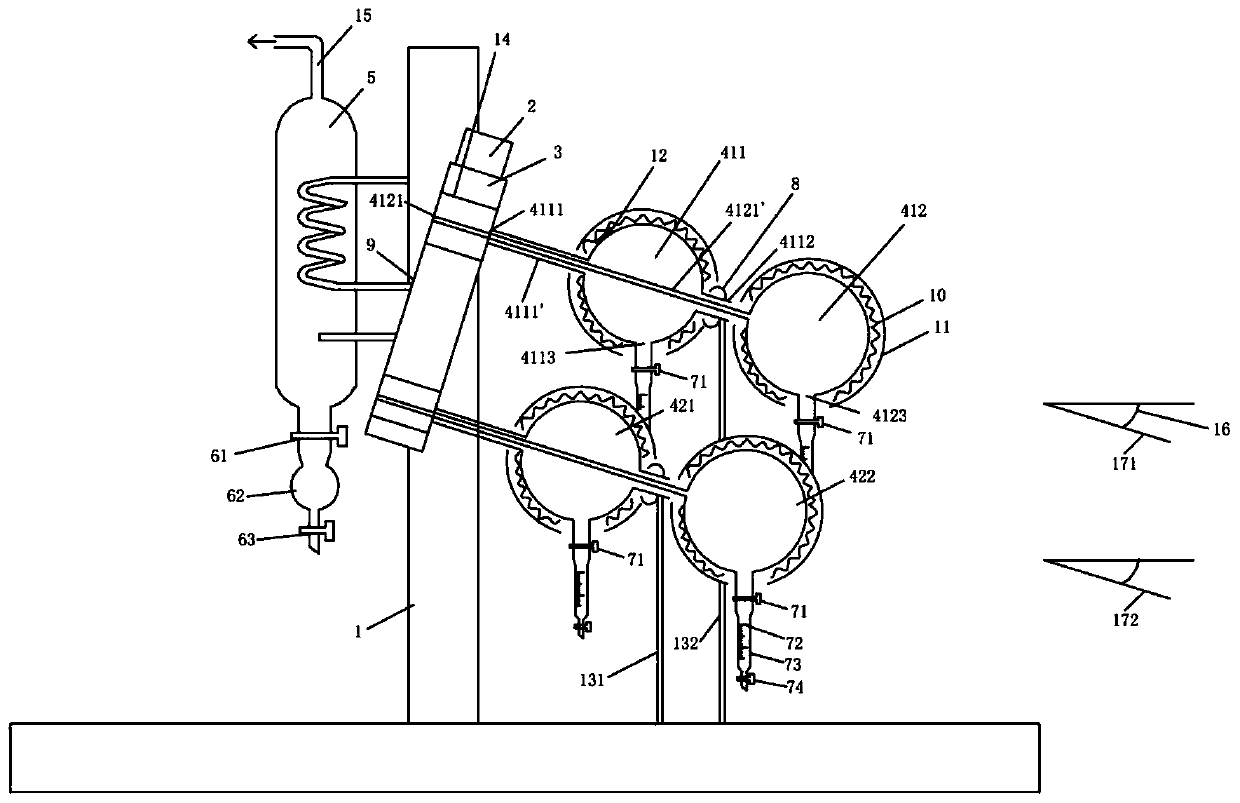

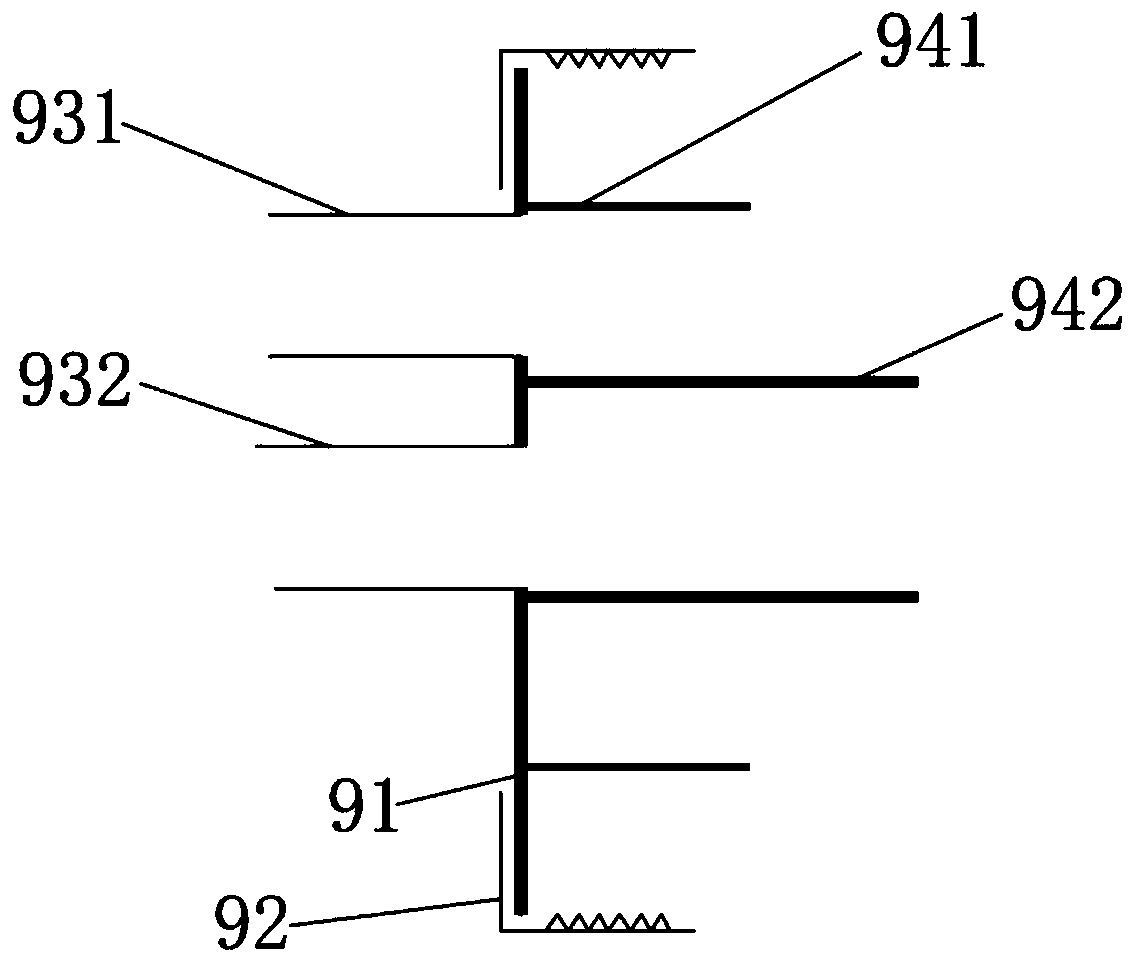

Rotary evaporator capable of accurately and quantitatively recovering several solvents at a time

PendingCN110404282AEliminate steric hindranceEasy to installDistillation regulation/controlVacuum distillation separationElectric heatingRotary evaporator

The invention relates to the technical field of chemical experiment devices, in particular to a rotary evaporator capable of accurately and quantitatively recovering several solvents at a time. According to the rotary evaporator, one distilling bottle, one condenser and one collecting bottle of an existing rotary evaporator are replaced with at least two distilling bottles, at least two condensersand at least two collecting bottles respectively, an existing water (oil) bath pot is replaced with an electric heating belt, and the condensers and the distilling bottles are communicated through connectors with porous pipe structures. All the distilling bottles are sequentially connected in series and rotate around the same axis. A down-tilting included angle of 2-44 degrees is formed between the rotating axis of the distilling bottles and the horizontal plane. A bracket support is arranged below the space between every two adjacent distilling bottles. All the condensers are vertically placed side by side. The upper side and the lower side of each collector are each provided with a valve, and a quantitative thin pipe is arranged between each valve and the corresponding side of the corresponding collector. No solvent evaporating, condensing and collecting pipelines are communicated. All the solvents can be accurately and quantitatively recovered on the premise of not detaching the collectors and not greatly influencing the negative pressure of the system.

Owner:BEIJING NORMAL UNIVERSITY

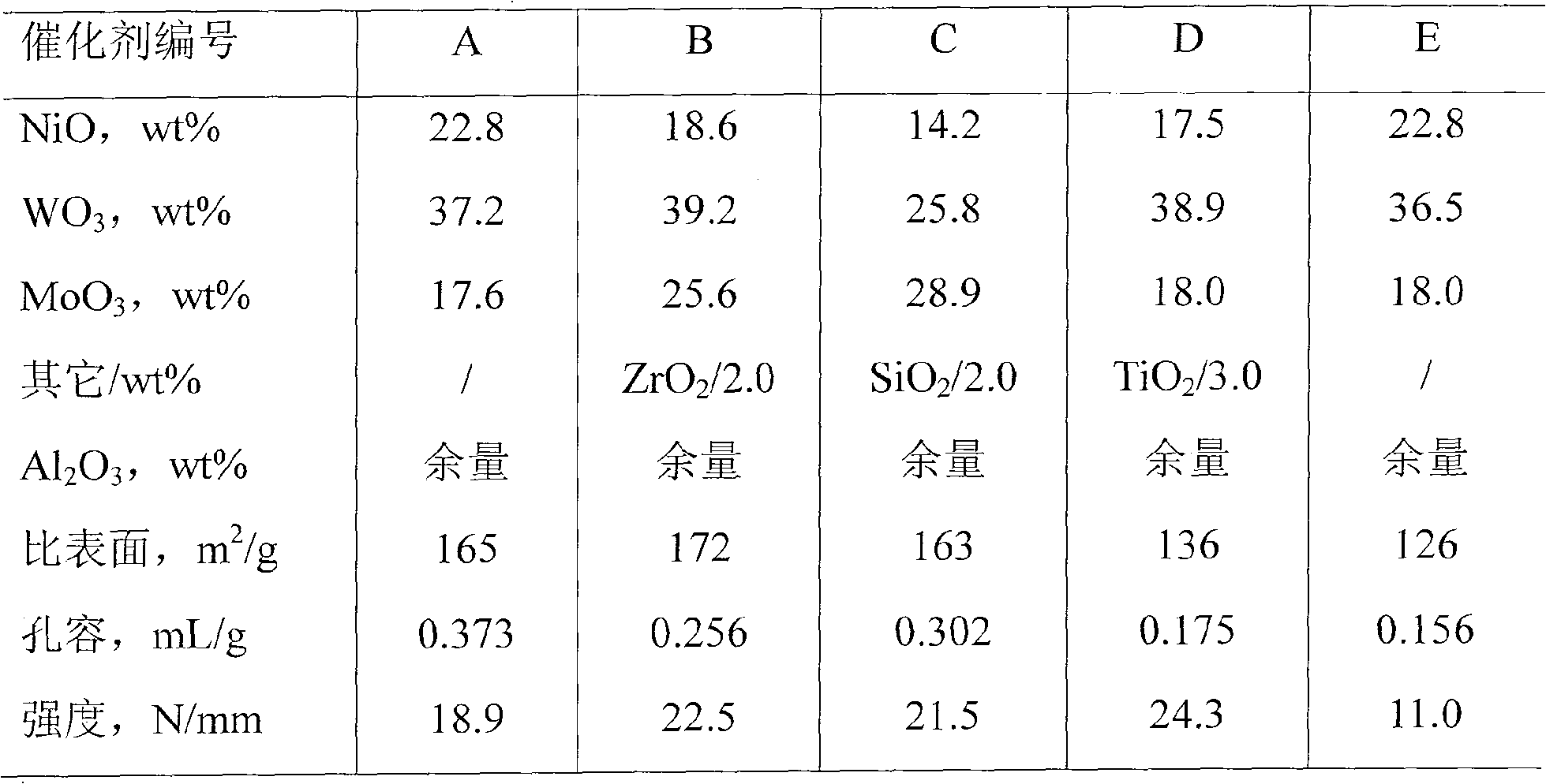

Preparation method for hydrogenation catalyst

ActiveCN102451708AOutstanding impurity removal activityImpurity removal activity improvedMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHigh activityExcessive growth

The present invention discloses a preparation method for a hydrogenation catalyst. According to the method, a coprecipitation method is adopted to generate a mixture comprising a NixWyOz composite oxide and a precursor of aluminum oxide; the mixture and MoO3 are subjected to beating, mixing, filtering, shaping, drying and baking to obtain the catalyst, wherein the method for generating the NixWyOz composite oxide and the precursor of the aluminum oxide by the coprecipitation method comprises: preparing an acid mixing solution A containing Ni, W, and an aluminum salt; preparing an aluminum-containing alkaline solution B; and carrying out co-current flow of the solution A and the solution B to carry out gelling to obtain the catalyst. According to the method of the present invention, the aluminum source comprises two parts, one is the acid mixing solution A, and the other is the aluminum-containing alkaline solution B, such that the excessive growth of the grain during the precipitation forming process can be effectively controlled, the reduction of the specific surface area of the catalyst can be inhibited, and the adhesion deteriorating of the catalyst can be inhibited so as to improve the pore structure and the mechanical strength of the catalyst. The method of the present invention is mainly applicable for the preparation of the bulk phase catalysts with the high metal content, wherein the bulk phase catalysts provide high activities for the deep impurity removal process of the hydrocarbon, and can be adopted to process the heavy raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production method of environment-friendly aromatic hydrocarbon oil for tires

ActiveCN111378498AAdaptableReduce lossesTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonProcess engineering

The invention discloses a production method of environment-friendly aromatic hydrocarbon oil for tires. The environment-friendly tire aromatic hydrocarbon oil meeting the European Union standard can be produced by taking positive-sequence furfural extract oil with a relatively high condensation point as a raw material and adopting a hydrotreatment-hydrodewaxing-solvent extraction combined process.The method comprises the following steps: performing hydrotreatment on raw materials under mild conditions to saturate polycyclic aromatic hydrocarbon, performing hydrodewaxing to reduce the condensation point to 0-10 DEG C, and finally performing shallow extraction to obtain the environment-friendly aromatic hydrocarbon oil for tires. The method expands sources of raw materials for producing theenvironment-friendly aromatic hydrocarbon oil, and has the characteristics of strong raw material adaptability and mild process conditions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing catalyst composition

ActiveCN1951559AHigh activityIncrease contentMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsDeposition processAmmonia

The invention relates to a method for preparing catalyst compound. Wherein, it uses deposition method to generate the forward body of NixWyOz compound oxide; then mixing and beating with MoO3, filtering, shaping and activating to obtain the final catalyst. The deposition process comprises that adding the salt mixture with active metals Ni and W into the reaction pot, adding dense ammonia to adjust the pH value to 10.0-13.0; heating to vaporize the ammonia, until the pH value is 7.5-9.0, and generating deposit, as the forward body. The invention can improve the catalyst property, with high metal content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Rotary evaporator capable of accurately and quantitatively condensing several samples at a time

PendingCN110404283ALess componentsReduce volumeDistillation regulation/controlVacuum distillation separationRotary evaporatorEngineering

The invention relates to the technical field of chemical experiment devices, in particular to a rotary evaporator capable of accurately and quantitatively condensing several samples at a time. According to the rotary evaporator, one distilling bottle of an existing rotary evaporator is replaced with a distilling bottle group with at least two distilling bottles, an existing water (oil) bath pot isreplaced with an electric heating belt, and all the distilling bottles in the distilling bottle group are sequentially connected in series and rotate around the same axis. A down-tilting included angle of 2-44 degrees is formed between the rotating axis and the horizontal plane. A bracket support is arranged below the space between every two adjacent distilling bottles. The lowest liquid surfaceof the working position of each distilling bottle is provided with a drain outlet which is connected with a scale metering thin pipe, the upper side and the lower side of each scale metering thin pipeare each provided with a valve, when the amount of a concentrated solution reaches the designed accurate amount, rotation is instantly stopped, the two valves are switched on and switched off accordingly, and the concentrated solutions in the distilling bottles can be accurately and quantitatively discharged on the premise of not detaching the collectors and not greatly influencing the negative pressure in the system.

Owner:BEIJING NORMAL UNIVERSITY

Method for processing printed circuit board by applying calixarene

ActiveCN106714464AImprove conductivityImprove adhesionConductive pattern formationCooking & bakingSilver paste

The invention discloses a method for processing a printed circuit board by applying calixarene. The method comprises the following steps that a) calixarene and an organic solvent are added to a container equipped with a stirring device under the normal temperature and the normal pressure and continuously stirred so as to obtain a calixarene solution; b) liquid silver paste and the calixarene soluation are added to a container equipped with a dispersing device under the normal temperature and the normal pressure and continuously dispersed and then discharged so as to obtain primary printing liquid; c) drilling and cleaning and other processing are performed on a substrate according to the line requirements and the substrate is arranged on a screen printing machine; d) printing liquid is added to the screen printing machine, and the primary printing liquid is coated on the substrate; and e) the substrate is arranged in a baking oven to be baked and then naturally cooled to the normal temperature and then the printed circuit board manufactured by applying calixarene can be obtained. The method for processing the printed circuit board by applying calixarene is high in environmental protection performance and can enhance the adhesive force of silver particles on the substrate so as to effectively reduce the processing cost of the printed circuit board.

Owner:GUANGDONG CHENGDE ELECTRONICS TECH CO LTD +1

Pretreatment liquid applied before analysis of pathogenic bacterium sample and pretreatment method

ActiveCN105699643AImprove the detection rateEliminate steric hindranceMaterial analysisAntigenPretreatment method

The invention relates to a pretreatment liquid applied before analysis of a pathogenic bacterium sample and a pretreatment method. The pretreatment liquid applied before analysis of the pathogenic bacterium sample is prepared from tris(hydroxymethyl) aminomethane, calcium salt, phospholipase, lysozyme and double distilled water; in terms of every 100 ml of the pretreatment liquid applied before analysis of the pathogenic bacterium sample, the content of tris(hydroxymethyl) aminomethane is 0.0121-0.121 g, the content of the calcium salt is 0.05-0.5 g in terms of the calcium element, the content of the phospholipase is 0.003-0.03 g, and the content of the lysozyme is 0.025-0.1 g; the pH of the pretreatment liquid applied before analysis of the pathogenic bacterium sample is 7.0-8.5. The pretreatment liquid applied before analysis of the pathogenic bacterium sample and the pretreatment method are provided, so that the sensitivity of direct pathogen detection methods such as colloidal gold, ELISA (enzyme linked immunosorbent assay) and the like on the basis of an antigen-antibody capture reaction is improved.

Owner:HUBEI UNIV OF TECH +1

Multi-rotating-shaft evaporator capable of accurately and quantitatively concentrating plurality of samples in one time

PendingCN110478928AEliminate steric hindranceEasy to installDistillation in rotating vesselsElectric heatingRotary evaporator

The invention relates to the technical field of chemical experiment equipment, in particular to a rotary evaporator, and particularly relates to a multi-rotating-shaft evaporator capable of accuratelyand quantitatively concentrating a plurality of samples in one time. The invention discloses a multi-rotating-shaft evaporator capable of accurately and quantitatively concentrating a plurality of samples at a time. One rotating shaft of an original rotary evaporator is increased to at least two rotating shafts. A declination included angle (a certain degree between 2 and 44 degrees) is formed between each rotating shaft and the horizontal plane; each rotating shaft is provided with one or more distillation flasks which are sequentially connected in series; a raw water (oil) bath pan is changed into an electric heating belt; an opening is formed in the lowest liquid level of the working position of each distillation flask and is connected with a concentrated solution gate bin with a concentrated solution quantifying and discharging function; the upper portion and the lower portion of the bin are each provided with a valve, the middle of the bin is provided with a scale metering pipe,distillation is stopped immediately when the amount of the concentrated solution reaches the designed accurate amount, the two valves are matched to be opened and closed, and accurate and quantitativedischarging of all the concentrated solutions can be achieved on the premise that a distillation flask does not need to be detached and negative pressure in a system is not greatly affected.

Owner:BEIJING NORMAL UNIVERSITY

Process for preparation of hydrogenation catalyst composition

ActiveCN1952054BHigh activityOutstanding impurity removal activityRefining to eliminate hetero atomsLoss rateSal ammoniac

The invention relates to the preparing method of a catalyst compound. The invention adopts coprecipitation to produce compound oxide predecessor, then pulp the predecessor and MoO3. After mixing the pulp, filtering, shaping and activating, the producers can get the catalyst. The producing procedure of NixWyOz includes the following steps: preparing the mixture that contains Ni and W, adding strong aqua to get A solution; preparing the mixture B that contains the added sunstances, mixing mixture B with strong aqua to get the gel and adding A to the gel; heating the material to vaporize the ammonia until the ph value reaches 7.5-9.0. The metal in the catalyst spreads uniformly and the volume of the bore is very large, so the catalyst can process heavy materials. The activity during the deepde-impurity process is even higher. The invention is characterized by simple method and low metal loss rate and it's mainly used to produce catalysts with higher metal content.

Owner:CHINA PETROLEUM & CHEM CORP +1

A catalyst composition and preparation method thereof

ActiveCN100448532CHigh activityIncrease contentMetal/metal-oxides/metal-hydroxide catalystsHydrogenMass ratio

The invention relates to a catalyst compound and relative preparation. Wherein, said compound comprises NixWyO2 compound oxide and MoO3, whose mass ratio is 1:10-10:1, and they are 40-100% of total mass. The inventive preparation comprises that using share deposition method to prepare the forward body of NixWyO2 compound oxide, to be mixed and beaten with MoO3; filtering, shaping and activating. The invention can adjust the cooperation between different metals, to obtain high property, with simple method and low metal loss. And the inventive catalyst is used in deep hydrogen process of hydrocarbons material.

Owner:CHINA PETROLEUM & CHEM CORP +1

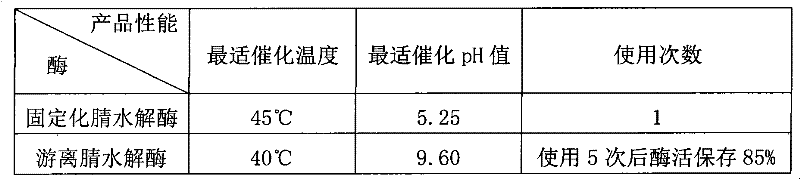

Method for preparing immobilized nitrilase

InactiveCN102517274AEliminate steric hindranceExpand the scope of spaceOn/in organic carrierMaterial resourcesEngineering industry

The invention which relates to a method for preparing an immobilized nitrilase belongs to the technical field of immobilized enzymes. According to the invention, the immobilized nitrilase is prepared by treating a nitrilase sold in the market as a raw material and a lysine-macroporous ion exchange resin sold in the market as a carrier, and carrying out simple processes of immobilization, suction filtration and lavation. The method of the invention has the advantages of simplicity and easy implementation, mild reaction condition, simple and easily available equipment, no discharge of "three wastes", full substance resource utilization, low production cost, and convenient popularization and application; and the immobilized nitrilase has the advantages of small steric hindrance effect, high heat stability, wide use range, and long service life. The method can be widely used for preparing the immobilized enzymes, and products prepared through adopting the method of the invention can be widely applied to the biodegradation industry, the bioremediation industry, the pharmaceutical industry, the chemical engineering industry, the agricultural industry and the like.

Owner:CHONGQING UNIV

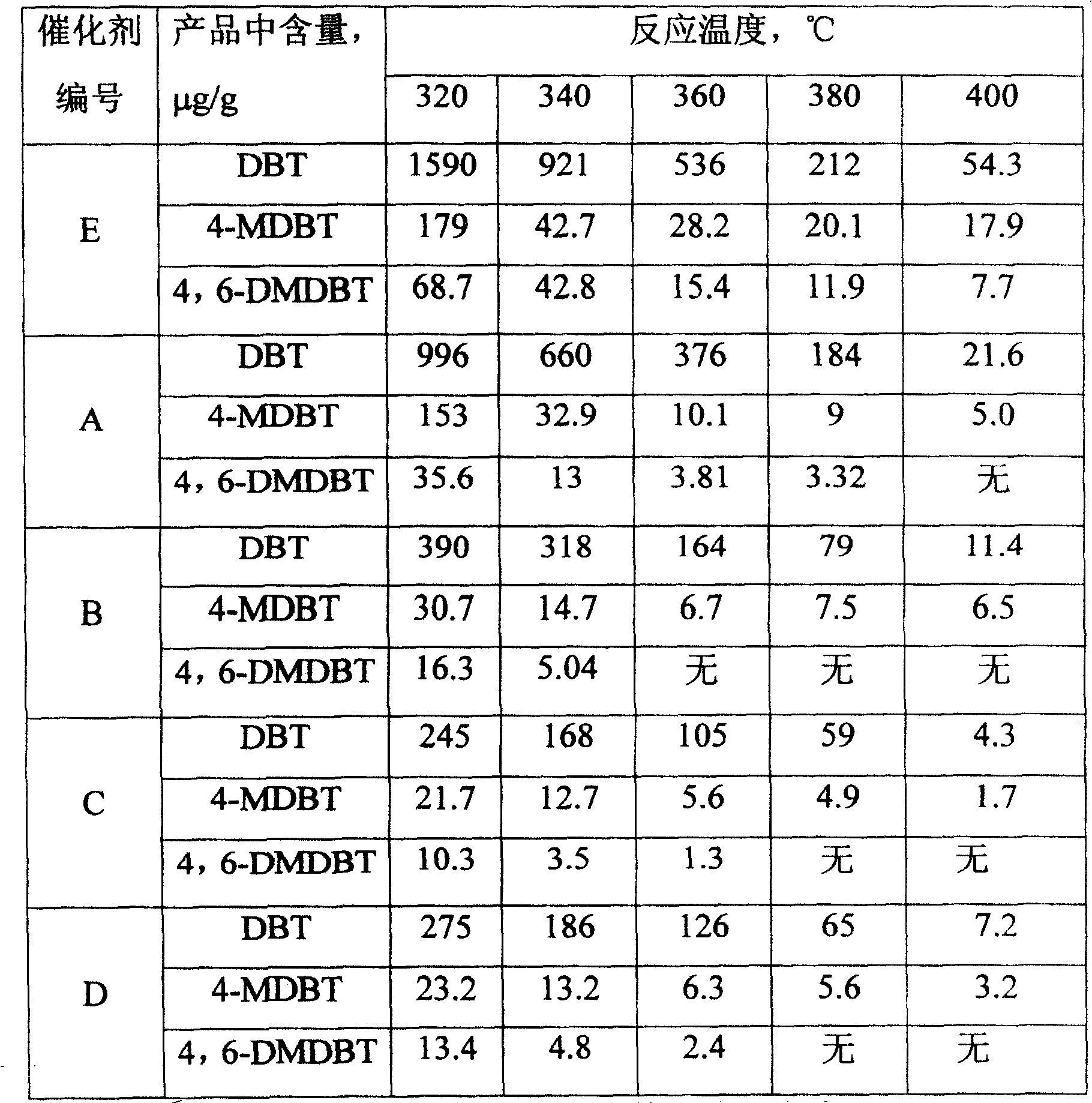

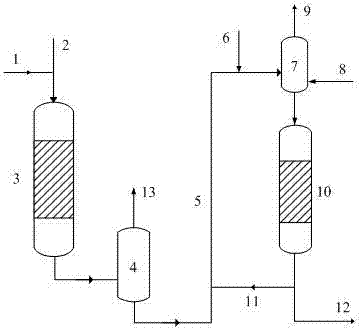

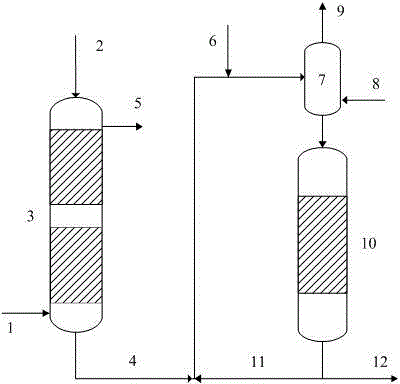

A kind of gas phase and liquid phase combined hydrogenation process method

ActiveCN103773471BImprove propertiesReduce hydrogen consumptionTreatment with hydrotreatment processesLiquid productGas phase

The invention discloses a gas phase-liquid phase circulating combined hydrogenation method. The gas phase-liquid phase circulating combined hydrogenation method comprises following steps: inferior diesel oil is subjected to gas phase hydrogenation reaction; a reaction effluent is delivered into a hot high pressure separator for separation, a liquid product is mixed with straight-run diesel oil, and an obtained mixture is delivered into a hydrogen mixing tank for saturated hydrogen dissolving, and then is delivered into a liquid phase circulating hydrogenation reactor for reaction; and then a low-sulfur diesel oil product is obtained. According to the gas phase-liquid phase circulating combined hydrogenation method, after gas phase hydrogenation reaction, aromatic hydrocarbons of the inferior diesel oil are saturated, hydrogen consumption of further reactions is relatively low, and saturated dissolved hydrogen content is increased; and at the same time, a large amount of hydrogen, which is not reacted, is dissolved in the obtained liquid phase effluent, enough dissolved hydrogen is provided for deep desulphurization reaction in the liquid phase circulating hydrogenation reactor, two-reverse charging properties are optimized, and it is beneficial for performing of deep hydrodesulfurization reaction. The invention provides the novel method used for producing ultra-low sulphur diesel oil by taking inferior diesel oil and straight-run diesel oil as raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

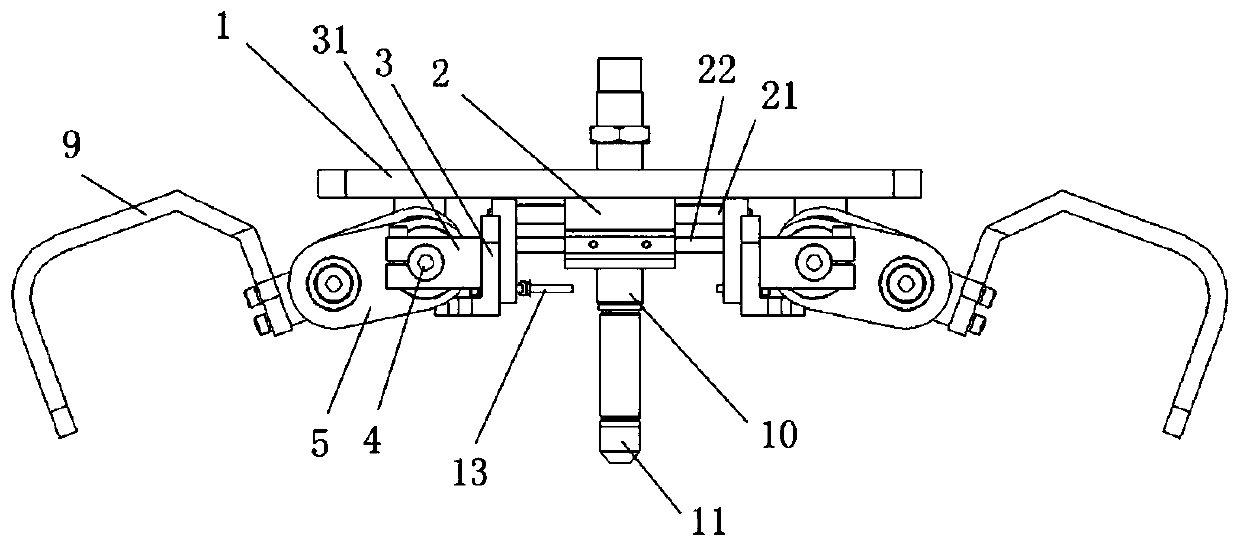

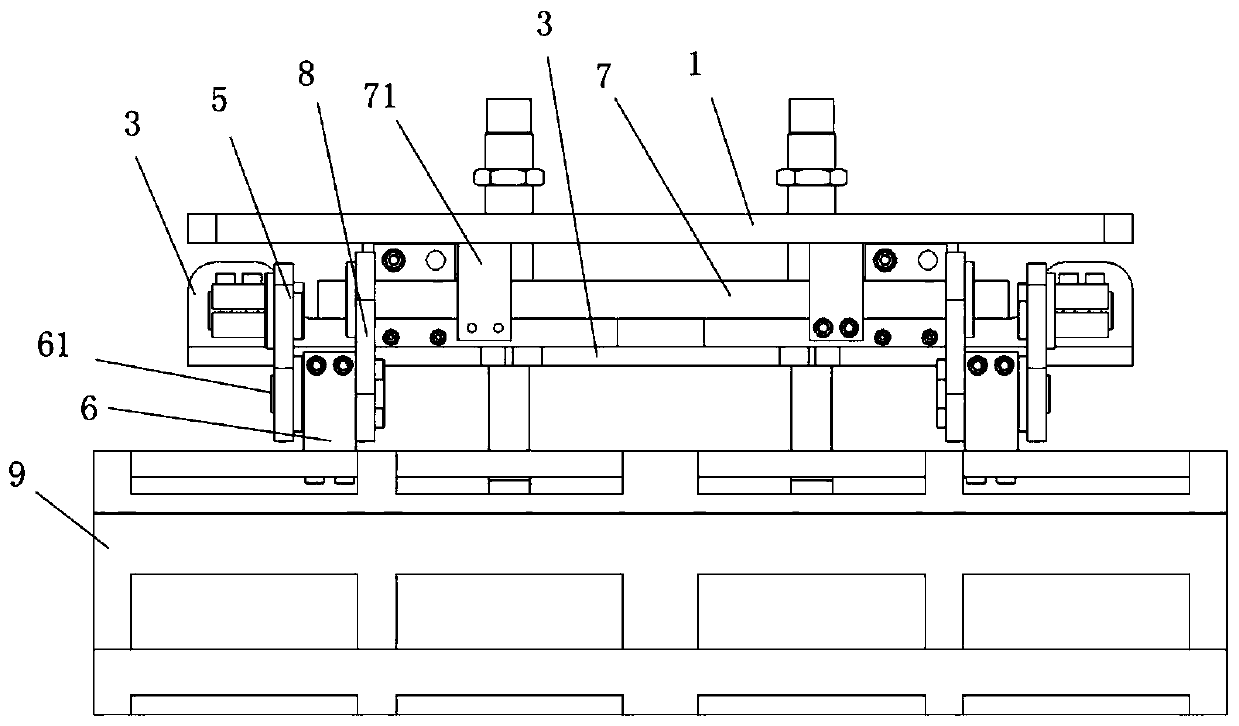

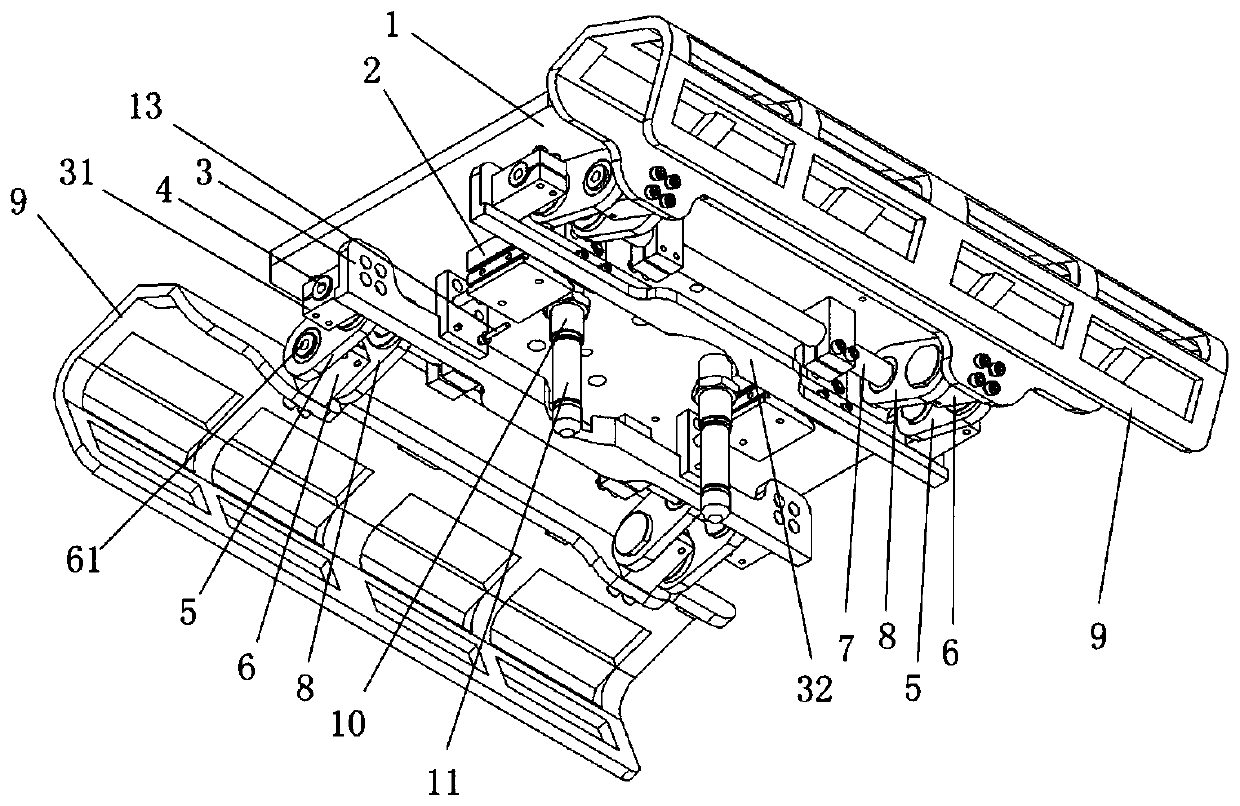

Arm unfolding gripper mechanism of industrial robot

PendingCN111360863AGuaranteed accuracyWork smoothly and stablyGripping headsControl engineeringControl theory

The invention provides an arm unfolding gripper mechanism of an industrial robot. The arm unfolding gripper mechanism comprises a gripper frame, a driving device, a pushing fixing piece, a movable rotating arm, a fixed rotating arm, a fixed shaft and push rods on the two sides of the gripper driving device, wherein the push rods drive the pushing fixing piece to horizontally move towards the two sides, the pushing fixing piece pushes the movable rotating arm and the fixed rotating arm to move, so that the movable rotating arm and the fixed rotating arm do composite motion; the inclination angle of the fixed rotating arm is changed while the fixed rotating arm moves outwards, the fixed rotating arm is gradually inclined from the vertical direction to the outside, and the fixed rotating armdrives a gripper to move, so that the gripper is opened towards the two sides; and when the driving device tightens the pushing fixing piece, the angle of the fixed rotating arm is gradually changed to the vertical direction, the fixed rotating arm drives the gripper to move, so that the gripper is tightened towards the inner side. According to the arm unfolding gripper mechanism, large-stroke movement of the gripper is realized through a small-stroke movement mechanism, and the capacity of the gripper is improved. The arm unfolding gripper mechanism is ingenious in structure, elegant in appearance, capable of rapidly and effectively driving the gripper to move, capable of guaranteeing that automatic feeding and discharging equipment is smooth and stable during working, high in applicability and beneficial to assembly, disassembly and maintenance.

Owner:项淮智能科技(长兴)有限公司

A combined method for producing high-quality lubricating oil base oil and environment-friendly aromatic hydrocarbon oil

ActiveCN111378500BImprove denitrification effectHigh saturationTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonProcess engineering

Owner:CHINA PETROLEUM & CHEM CORP +1

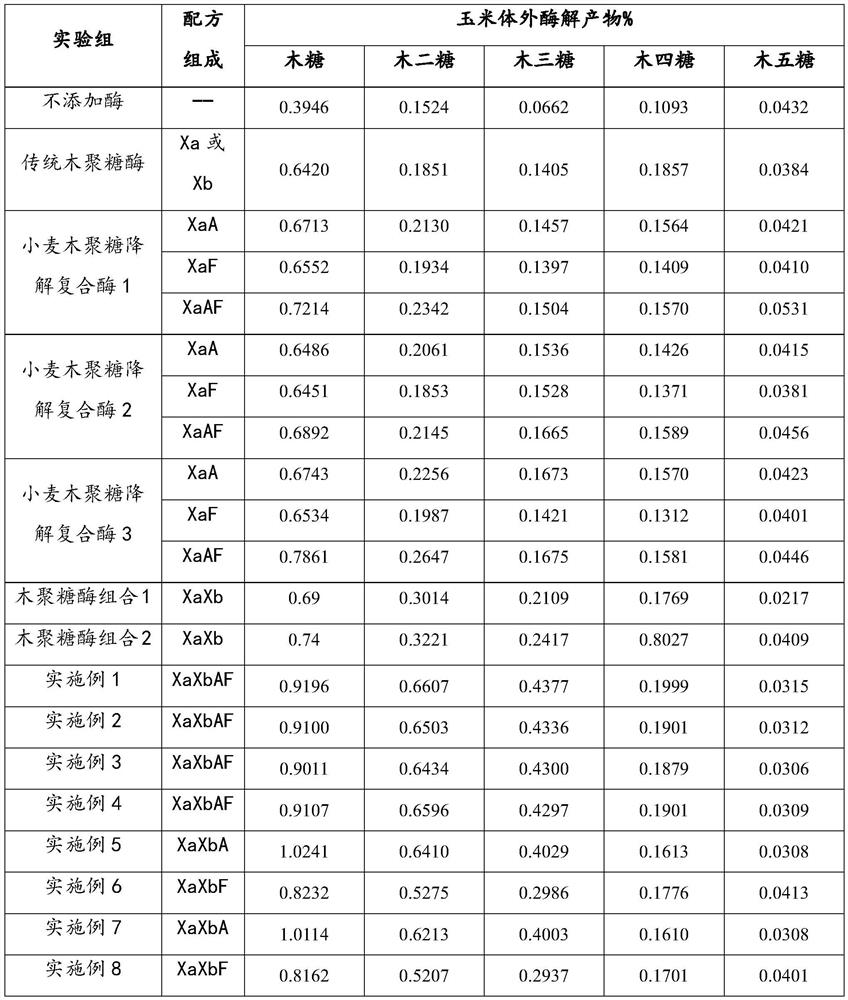

A compound enzyme composition for degrading corn xylan

ActiveCN109679934BImprove degradation efficiencyImprove digestibilityAnimal feeding stuffAccessory food factorsXylanFerulic acid esterase

Owner:JINANBESTZYME BIO ENG CO LTD

A gas phase and liquid phase mixed hydrogenation process method

ActiveCN103773458BLow impurity contentImprove propertiesTreatment with hydrotreatment processesHydrodesulfurizationGas phase

Owner:CHINA PETROLEUM & CHEM CORP +1

A method of applying calixarene to process printed circuit boards

ActiveCN106714464BImprove conductivityImprove adhesionConductive pattern formationScreen printingCooking & baking

The invention discloses a method for processing a printed circuit board by applying calixarene. The method comprises the following steps that a) calixarene and an organic solvent are added to a container equipped with a stirring device under the normal temperature and the normal pressure and continuously stirred so as to obtain a calixarene solution; b) liquid silver paste and the calixarene soluation are added to a container equipped with a dispersing device under the normal temperature and the normal pressure and continuously dispersed and then discharged so as to obtain primary printing liquid; c) drilling and cleaning and other processing are performed on a substrate according to the line requirements and the substrate is arranged on a screen printing machine; d) printing liquid is added to the screen printing machine, and the primary printing liquid is coated on the substrate; and e) the substrate is arranged in a baking oven to be baked and then naturally cooled to the normal temperature and then the printed circuit board manufactured by applying calixarene can be obtained. The method for processing the printed circuit board by applying calixarene is high in environmental protection performance and can enhance the adhesive force of silver particles on the substrate so as to effectively reduce the processing cost of the printed circuit board.

Owner:GUANGDONG CHENGDE ELECTRONICS TECH CO LTD +1

A kind of method utilizing calixarene to process printed circuit board

ActiveCN106686900BImprove conductivityImprove adhesionLithography/patterningConductive pattern formationLiquid layerCooking & baking

The invention discloses a method for processing a printed circuit board by using calixarene. The method comprises the following steps of (a) adding the calixarene and an organic solvent to a container with a stirring device at a room temperature and atmospheric pressure and lastingly stirring to obtain a printing liquid; (b) carrying out treatment of drilling, cleaning and the like on a substrate and putting the substrate on one screen printing machine; (c) adding the printing liquid to the screen printing machine and rubbing the substrate with the printing liquid; (d) putting the substrate in the environments of the room temperature and the atmospheric pressure, naturally airing for later use and forming a printing liquid layer by the printing liquid on the substrate; (e) putting the substrate on a screen printing table of another screen printing machine, adding liquid silver paste to the screen printing machine and rubbing the printing liquid layer with the silver paste; and (f) putting the substrate obtained in the step (e) into an oven for baking, and naturally cooling to obtain the printed circuit board. The method for processing the printed circuit board by using the calixarene is high in environmental protection property, the adhesive force of silver particles on the substrate can be improved and the impedance of a conducting circuit can be reduced.

Owner:GUANGDONG CHENGDE ELECTRONICS TECH CO LTD +1

Preparation of hydrogenation catalyst

ActiveCN100589878CHigh activityIncrease contentCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsLoss rateCoprecipitation

The invention relates to a preparation method of catalyst composition. The precursor of NixWyOz composite oxide is generated by adopting the coprecipitation method, and then is mixed and pulped with MoO3, filtered, molded and activated into final catalyst. The method of generating the precursor of the NixWyOz composite oxide by adopting the coprecipitation method comprises the following steps: salt mixed solution A including reactive metal Ni, W component and promoter is prepared according the content compounding ratio of the catalyst components. Sodium metalluminate solution B is prepared according to the content proportion of the catalyst component. The solution A and the solution B are added into a reaction pot filled with purified water for gelling, so as to prepare gelatinous mixturewhich is the precursor of the NixWyOz composite oxide. The catalyst prepared by the method of the invention has uniform distribution of the metal and high service performance, and higher activity, particular to the deep impurity casting process of hydrocarbon. In addition, the method of the invention is simple, and the loss rate of the metal is low. The invention is mainly used for preparing bulkphase catalyst with high metal content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com