A compound enzyme composition for degrading corn xylan

A technology of xylanase and compound enzyme, applied in the direction of hydrolase, glycosylase, enzyme, etc., can solve the problems of low degradation efficiency, difficulty in achieving effective and sufficient degradation of xylan, and achieve improved digestibility and degradation The effect is remarkable and the effect of improving the degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

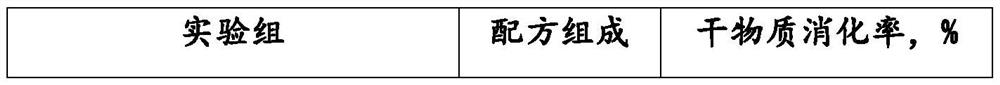

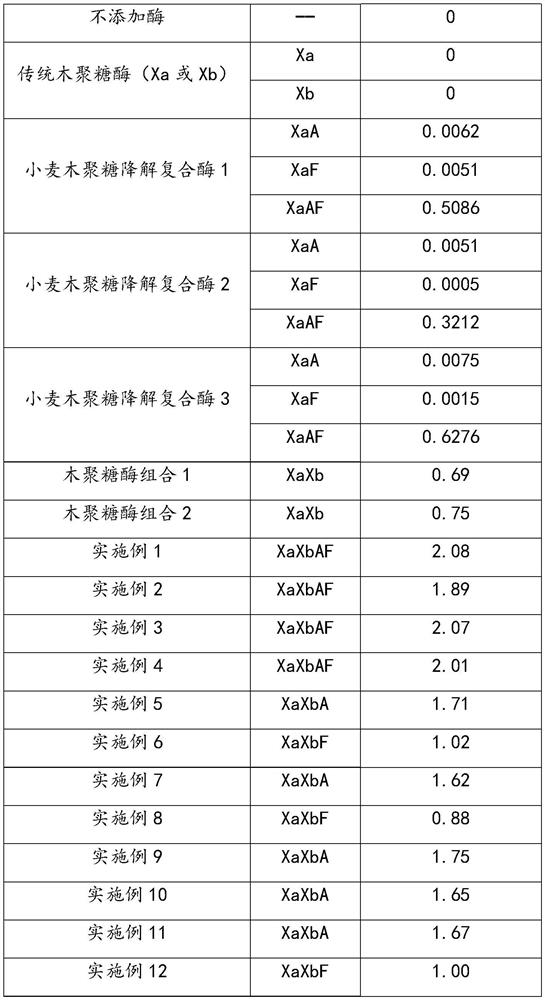

Embodiment 1

[0023] The active components of the composite enzyme composition for degrading corn xylan include xylanase a: β-1,4-endo-xylanase 3580U / g, xylanase b: β-1,4-exo-xylanase Cut xylanase 40100U / g, α-L-arabinofuranosidase 485U / g and ferulic acid esterase 132U / g.

Embodiment 2

[0025] The active components of the composite enzyme composition for degrading corn xylan include xylanase a: β-1,4-endo-xylanase 2000U / g, xylanase b: β-1,4-exo-xylanase Cut xylanase 20000U / g, α-L-arabinofuranosidase 200U / g and ferulic acid esterase 50U / g.

Embodiment 3

[0027] The active components of the composite enzyme composition for degrading corn xylan include xylanase a: β-1,4-endo-xylanase 5000 U / g, xylanase b: β-1,4-exo-xylanase Cut xylanase 50000U / g, α-L-arabinofuranosidase 1500U / g and ferulic acid esterase 200U / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com