Catalyst for catalytic oxidization of volatile organic compound, as well as preparation method of catalyst

A volatile organic compound, catalytic oxidation technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., to achieve the effect of eliminating steric reaction steric hindrance, large specific surface area, and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

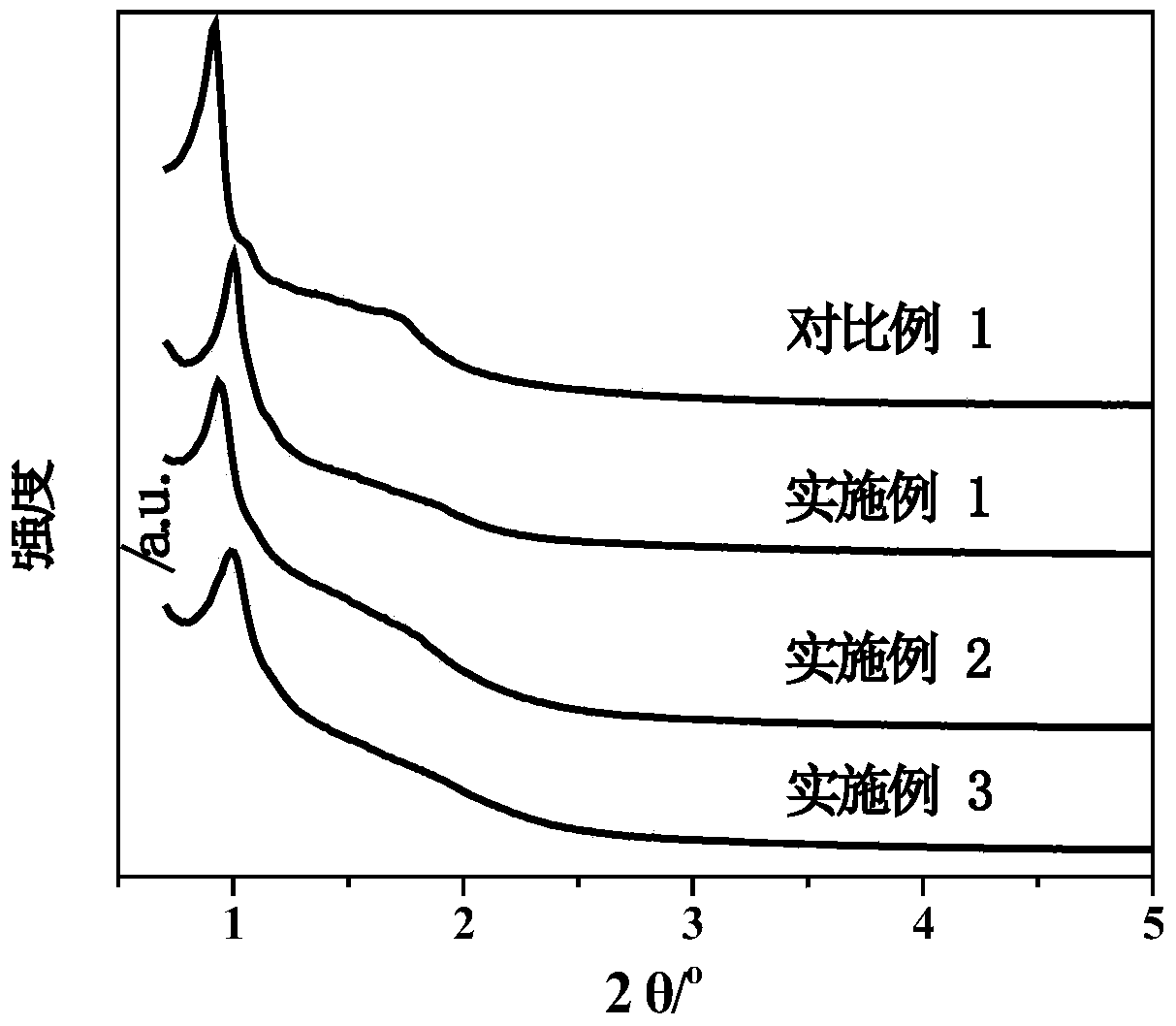

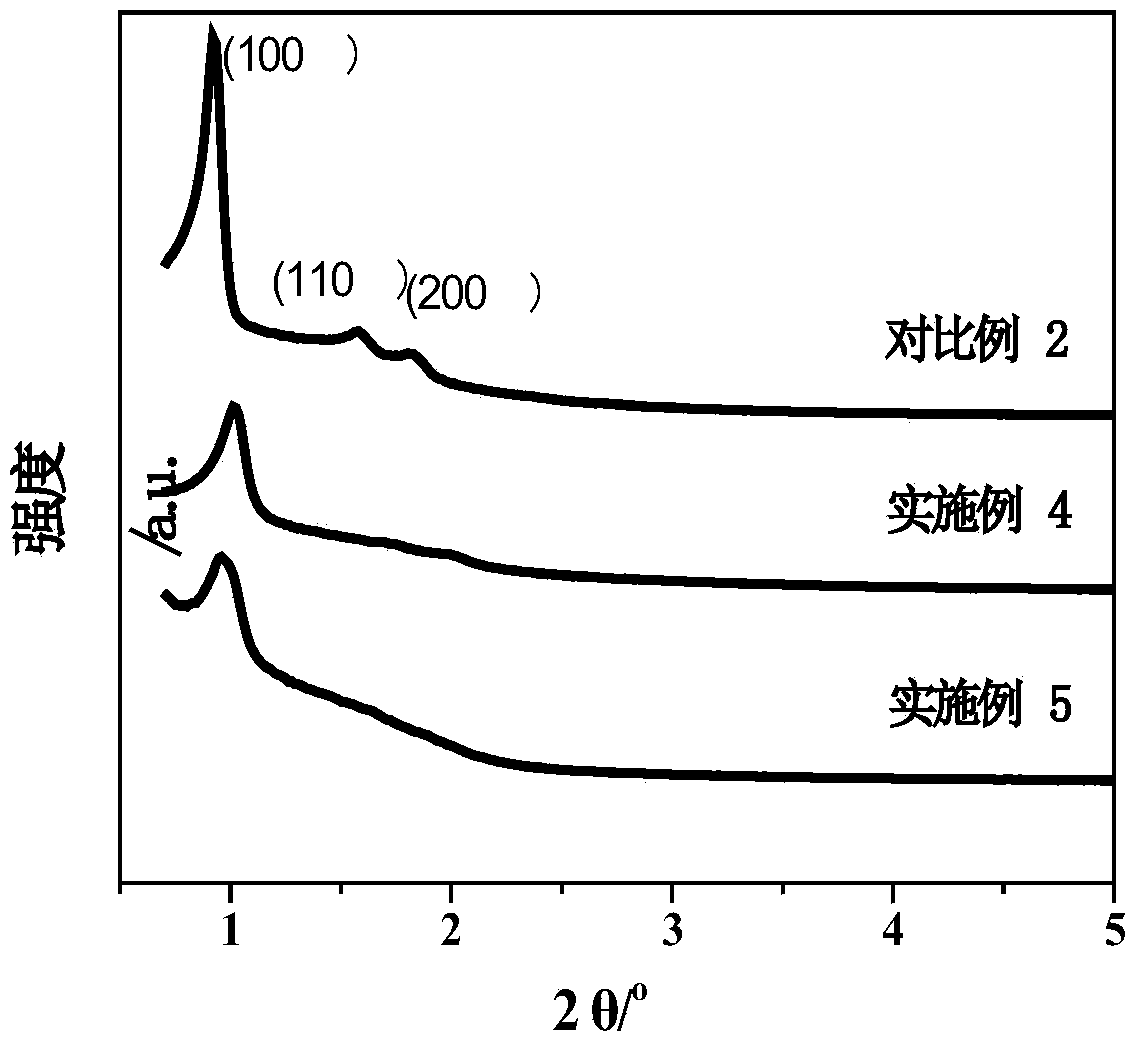

Embodiment 1

[0017] (1) Preparation of hierarchically porous KIT-6 molecular sieve carrier with macroporous-mesoporous structure

[0018] Dissolve 1g P123 and 1g n-butanol in a mixed solution of 36mL deionized water and 1.9g hydrochloric acid (37wt%), stir at 35°C until P123 is completely dissolved; The mass ratio of tetraethyl ester (TEOS) was 0.3:1, and 0.645 g of polystyrene microspheres (PS) was added thereto. After the PS was completely dissolved in the solution, 2.15 g of TEOS was added, kept stirring for 24 h, and then transferred to a reactor for crystallization at 100 ° C for 24 h. They were washed and filtered with deionized water and ethanol respectively, dried in an oven, and finally calcined at 550° C. for 5 hours in an air atmosphere. The hierarchically porous KIT-6 molecular sieve carrier with macropore-mesoporous structure can be obtained, which is marked as MMK-1.

[0019] (2) Preparation of Pt-supported Hierarchical Porous KIT-6 Catalyst

[0020] Using the impregnation...

Embodiment 2

[0024] Prepare 0.7wt.% Pt loaded hierarchical porous KIT-6 catalyst according to the method for example 1, difference is, the mass ratio that changes polystyrene microsphere (PS) and tetraethyl orthosilicate (TEOS) is 1: 1. The obtained catalyst is marked as 0.7wt.%Pt / MMK-2.

[0025] Catalyst carries out active measurement on the device described in above-mentioned embodiment 1, and the result shows that the catalyst that embodiment 2 makes is the gas (all the other gas components 21% O 2 and 79%N 2 ), at a reaction space velocity of 80,000h -1 The temperature for complete catalytic oxidation is 265°C.

Embodiment 3

[0027] Prepare 0.3wt.% Pt loaded hierarchical porous KIT-6 catalyst according to the method of Example 1, the difference is that the mass ratio of polystyrene microspheres (PS) to tetraethyl orthosilicate (TEOS) is 2:1 , the obtained catalyst is labeled as 0.3wt.%Pt / MMK-3.

[0028] Catalyst carries out active measurement on the device described in above-mentioned embodiment 1, and the result shows that the gas (all the other gas components 21% O 2 and 79%N 2 ), at a reaction space velocity of 80,000h -1 The temperature for complete catalytic oxidation is 263°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com