Method for preparing immobilized nitrilase

A technology of nitrilase and immobilized nitrile, which is applied in the direction of fixing on/in the organic carrier, can solve the problems of large material transfer resistance, unfavorable sustainable development, low enzyme reaction speed, etc., and achieve low production cost, Conducive to sustainable development and high resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

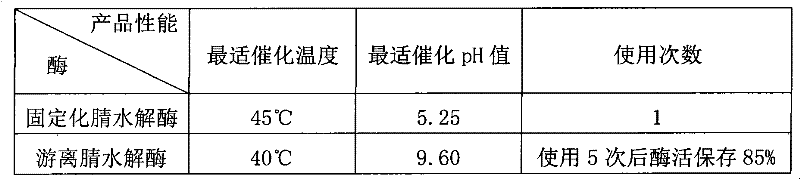

Image

Examples

Embodiment 1

[0022] A method for preparing immobilized nitrilase, the specific method steps are as follows:

[0023] (1) Pretreatment of nitrilase

[0024] Using commercially available nitrilase as raw material, according to the mass (g) of commercially available nitrilase: the volume (mL) ratio of buffer solution is 1:10, add commercially available nitrilase into the buffer solution, stir to dissolve After 40 minutes, it is pumped into the suction filter for suction filtration, and the suction filtrate and the suction filter residue are collected respectively. The collected suction filtrate is used to prepare immobilized nitrilase for treatment; the collected suction filter residue is dried and used to add animal feed. Wherein, the buffer solution is a borax-calcium chloride buffer solution with a pH value of 8.0.

[0025] (2) Preparation of immobilized nitrilase crude product

[0026] After the (1) step was completed, according to the quality (g) of the commercially available lysine-m...

Embodiment 2

[0032] A method for preparing immobilized nitrilase, with embodiment 1, wherein:

[0033] In the 1st step, the mass of commercially available nitrilase: the volume ratio of buffer solution is 1g: 9mL, stirring and dissolving for 35 minutes, wherein, described buffer solution is the borax-potassium chloride buffer solution with a pH value of 9.0 .

[0034] In (2) step, the quality of commercially available lysine-macroporous ion exchange resin carrier: the volume of the suction filtrate collected in (1) step: glutaraldehyde mass concentration is the volume ratio of 25% glutaraldehyde solution 1g: 2.5mL: 0.7mL, soak in buffer solution for 2.5 hours, heat up to 35°C, and react at constant temperature for 6.5 hours, wherein the buffer solution is a borax-potassium chloride buffer solution with a pH value of 9.0.

[0035] In step (3), the quality of the suction filter residue collected in step (2): the volume ratio of distilled water is 1g: 4.5mL, and the collected washing residue...

Embodiment 3

[0038] A method for preparing immobilized nitrilase, with embodiment 1, wherein:

[0039]In the 1st step, the quality of commercially available nitrilase: the volume ratio of buffer solution is 1g: 8mL, stirring and dissolving 30 minutes, wherein, described buffer solution is the borax-calcium carbonate buffer solution that pH value is 10.8.

[0040] In (2) step, the quality of commercially available lysine-macroporous ion exchange resin carrier: the volume of the suction filtrate collected in (1) step: glutaraldehyde mass concentration is the volume ratio of 25% glutaraldehyde solution 1g: 3mL: 0.8mL, soak in the buffer solution for 3 hours, heat up to 45°C, and react at constant temperature for 7 hours, wherein the buffer solution is a borax-calcium carbonate buffer solution with a pH value of 10.8.

[0041] In step (3), the quality of the suction filter residue collected in step (2): the volume ratio of distilled water is 1g: 5mL, and the collected washing residue is stored...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com