Method for preparing gasoline and diesel by oil washing hydrogenation

A technology for hydrogen preparation and oil washing, which is applied in the production field of high-quality gasoline and diesel products, and achieves the effects of low impurity content, large improvement range and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

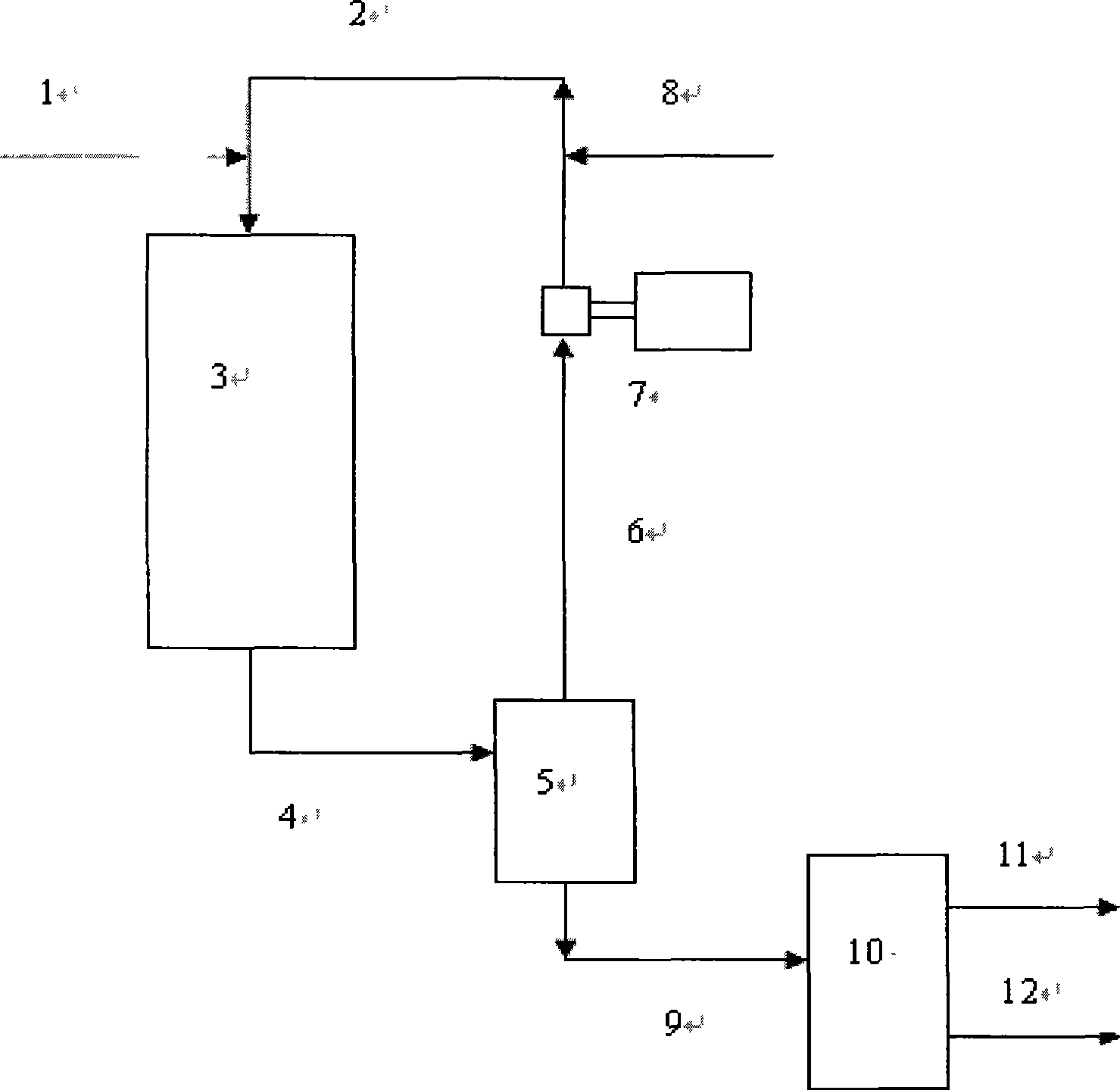

[0017] The solutions and effects of the present invention will be described in more detail below in conjunction with the drawings and embodiments.

[0018] like figure 1 As shown, in the following preferred embodiments of the present invention, the purified washed oil 1 is first mixed with hydrogen 2 and enters the hydrogenation reactor 3 to obtain the hydrogenated oil 4 and enters the high-pressure separator 5 for gas-liquid separation, and the obtained gas 6 is recycled after being pressurized by the circulating hydrogen compressor 7, and the separated liquid 9 enters the stripping tower 10 (or fractionating tower) for fractional distillation according to the amount of gasoline (naphtha) to obtain gas products, gasoline (naphtha) 11, Diesel 12.

[0019] Table 1 lists the properties of the washing oil raw material used in the following examples 1-4.

[0020] Table 1 Properties of washing oil

[0021] Raw oil Wash oil 1 Wash oil 2 Distillation range, ℃ 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com