Multi-wire tightly winding device for enamelled wire

A technology of tensioning device and enameled wire, which is applied in the direction of electrical components, inductance/transformer/magnet manufacturing, circuits, etc., can solve the problems that cannot meet the requirements of equipment, asynchronous tensioning process, slow response speed, etc., and achieve simple structure, Meet the functional requirements and increase the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

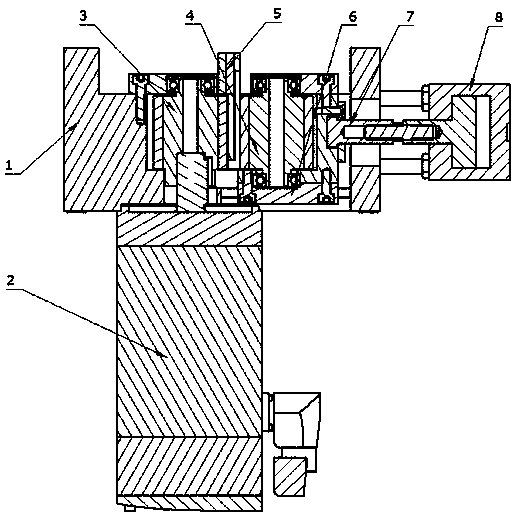

[0008] The specific embodiment: with reference to accompanying drawing. A multi-wire tensioning device for enameled wires. The motor base 1 is equipped with a servo motor 2, and the main shaft of the servo motor 2 is provided with a driving roller 3 with a rubber film to cooperate with a driven roller 4 with a rubber film fixed on the sliding seat 6, and the sliding seat 6 passes through the connecting shaft. 7 is connected with the piston rod of the cylinder 8, and the motor base 1 is provided with a wiring mold 5 located between the driving roller 3 and the driven roller 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com