Sandwich structure magnetic composite micro ball with functional shell layer, its preparing method and use

A technology of magnetic composite microspheres and sandwich structure, which can be applied to the preparation methods of peptides, biochemical equipment and methods, chemical instruments and methods, etc., and can solve problems such as insufficient magnetic characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation process of the magnetic composite microsphere of the present invention is divided into two stages: the first stage is to prepare the magnetic polymer composite microsphere with the core-shell structure of Chinese patent application 200510087784.7; the second stage is to prepare the magnetic composite microsphere with the core-shell structure. The polymer composite microsphere is the initial material, which is covered with one or two types of functionalized shell layers.

[0025] The coating method of the functionalized shell varies according to the category it belongs to. Even in the same category, due to the different specific materials, the specific formulation processes used are different. The coating methods of various functionalized shells can be summarized as follows:

[0026] The first type: Generally, magnetic polymer composite microspheres with a core-shell structure are dispersed in a solution of the polymer to be coated. Relying on interacti...

Embodiment 1

[0063] PS / Fe 3 o 4 / SiO 2 Preparation of Magnetic Composite Microspheres (Method 1)

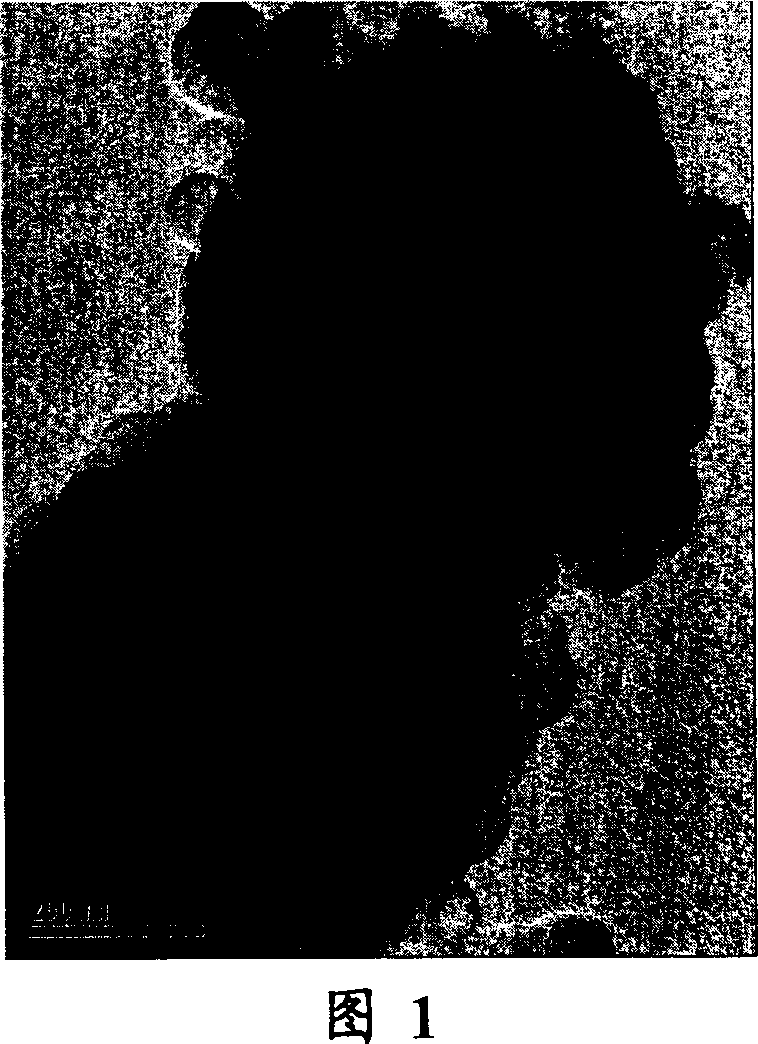

[0064] Ultrasonically disperse 0.01g of magnetic composite microspheres from Reference Example 4 into 100mL of absolute ethanol, adjust the pH value of the system to 9 with ammonia water, and keep the temperature in a constant temperature water bath at 40°C; then add 0.1mL of orthosilicic acid dropwise Ethyl alcohol solution (the volume ratio of ethyl orthosilicate and ethanol is 1:1), kept constant temperature, and reacted for 12 hours under the action of mechanical stirring. After the reaction is completed, the product is separated by using a magnetic field, washed several times with absolute ethanol, and finally dispersed in absolute ethanol for cold storage. The transmission electron micrograph of the composite microsphere is shown in Fig. 1 .

Embodiment 2

[0066] PS / Fe 3 o 4 / SiO 2 Preparation of Magnetic Composite Microspheres (Method 2)

[0067] Ultrasonic dispersion of 0.25g of magnetic composite microspheres from Reference Example 6 into 100mL of isopropanol was added to 7mL of ammonia water (concentration of 25%), and the temperature was kept constant in a constant temperature water bath at 40°C; then a certain amount of ethyl orthosilicate was added ester, make the concentration of ethyl orthosilicate in the system 4.0mmol / L, keep constant temperature, and react for 12 hours under the action of mechanical stirring. After the reaction is completed, the product is separated by using a magnetic field, washed several times with absolute ethanol, and finally dispersed in absolute ethanol for cold storage. The specific saturation magnetization of the product was 15.2 emu / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com