Novel magnetic Fe / C@ MOF composite absorbent and preparation method thereof

A composite material and adsorbent technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, alkali metal compounds, etc., can solve the problems of weak magnetism and inability to magnetic separation, and achieve short carbonization time, low price, and reaction conditions. mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of a novel magnetic Fe / CMOF composite adsorbent, the specific steps are as follows:

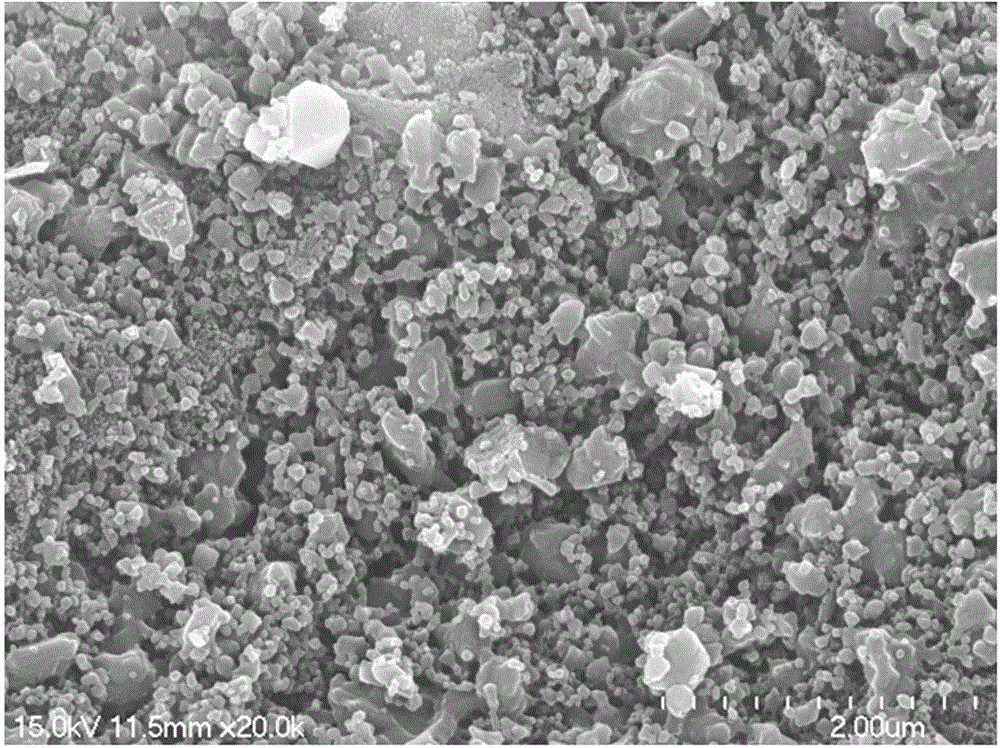

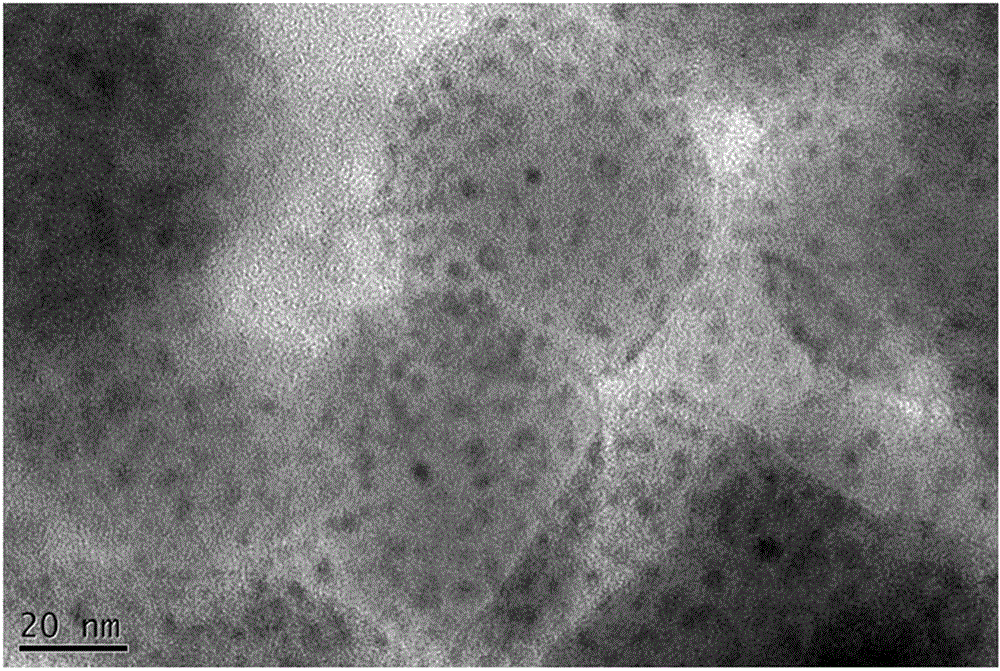

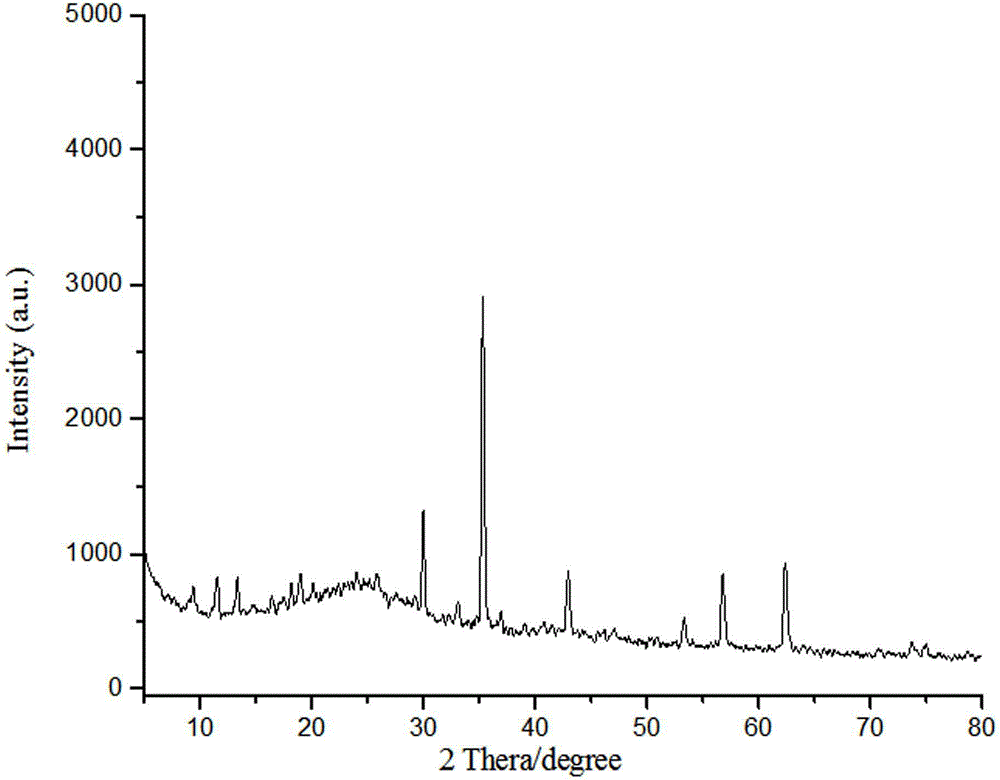

[0027] (1) Synthesis of magnetic Fe / C materials

[0028] Weigh 5.0 g starch and FeCl respectively 3 ·6H 2 Put 4.0 g of O in an Erlenmeyer flask, add 40 mL of water, and place it in a constant temperature magnetic stirrer at 50 ℃ in a constant temperature water bath with magnetic stirring overnight. After completion, it was placed in a household microwave oven and heated at 600 W for 50 s to obtain a bright red gel. The obtained gel was dried in a forced-air drying oven at 80 ℃ for 10 h, and then dried in a vacuum drying oven at 80 ℃ overnight to obtain a light yellow solid. Weigh the obtained light yellow solid and 10.0 g of anhydrous zinc chloride in a ratio of 1:4, quickly grind it evenly in a mortar and transfer to a beaker, place it in a household microwave oven and heat it with 600 W microwave for 3 min. After cooling, obtain a black solid with water Repeated was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com