Preparation method for inorganic-organic composite adhesive-coated soft magnetic composite

An organic binder and inorganic composite technology, applied in the direction of magnetic properties of inorganic materials, can solve the problem of not specifying the composite method, and achieve the effect of improving the coating effect, improving the high-frequency performance and quality factors, and excellent magnetic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

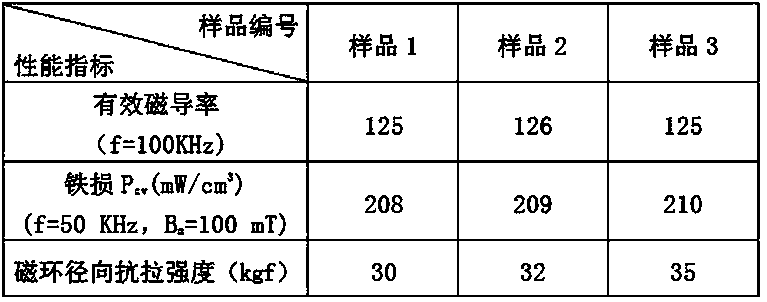

Embodiment 1

[0016] (1) Take an appropriate amount of pure iron powder and mix iron powders of different meshes. The iron powder powder with a particle size of -100 mesh to +200 mesh accounts for 10% of the total mass, and the iron powder of -200 mesh to +400 mesh Powder accounts for 60% of the total mass, and iron powder with a mesh size of 400 or more accounts for 30% of the total mass.

[0017] (2) Passivate the configured iron powder with phosphoric acid, stir and dry in a water bath at 60 °C to obtain passivated iron powder. The mass of phosphoric acid accounts for 1wt% of the total mass of iron powder.

[0018] (3) Dissolve the epoxy resin with acetone, and dissolve the low-melting glass powder with xylene, then mix the two together, and stir for 30 min in a water bath at 50 °C to obtain a uniformly mixed composite binder, and then mix with iron The powder is stirred and mixed, mixed evenly and then dried. The mass of the epoxy resin is 0.5 wt% of the total mass of the magnetic pow...

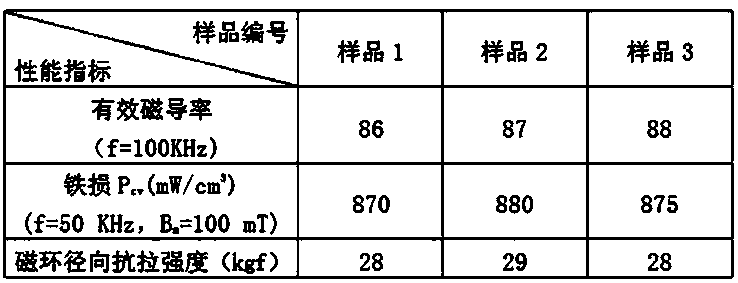

Embodiment 2

[0024] (1) Take an appropriate amount of sendust magnetic powder, mix sendust magnetic powder with different meshes, the particle size of the sendust magnetic powder can reach -100 mesh~+200 mesh, account for 30% of the total mass, and -200 mesh~+ 400 mesh sendust magnetic powder accounts for 40% of the total mass, and sendust magnetic powder above 400 mesh accounts for 30% of the total mass.

[0025] (2) Passivate the configured sendust magnetic powder with phosphoric acid, stir and dry in a water bath at 80°C to obtain passivated sendust powder. The mass of phosphoric acid accounts for 0.4wt% of the total mass of sendust magnetic powder.

[0026] (3) Dissolve the silicone resin in xylene, and the low-melting point glass powder in xylene, then mix the two together, and stir for 30 minutes in a water bath at 50°C to obtain a uniformly mixed composite binder, and then Stir and mix with sendust powder, mix evenly and then dry. The mass percentage of the silicone resin is 2% by...

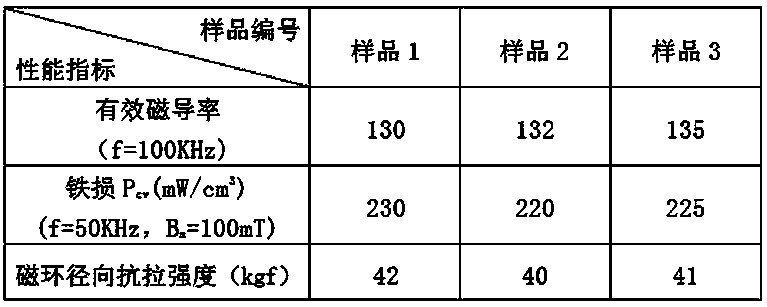

Embodiment 3

[0031](1) Take an appropriate amount of iron-nickel-molybdenum magnetic powder (containing iron 17.0%, Mo2.0%, Cu1.0%, Al+Si<1.0%, the rest is Ni), and mix iron-nickel-molybdenum magnetic powder with different meshes The iron-nickel-molybdenum magnetic powder with a particle size of -100 mesh to +200 mesh accounts for 30% of the total mass, the iron-nickel-molybdenum magnetic powder powder of -200 mesh to +400 mesh accounts for 50% of the total mass, and the iron-nickel-molybdenum magnetic powder with a particle size of more than 400 mesh 20% of the total mass.

[0032] (2) Passivate the configured iron-nickel-molybdenum magnetic powder powder with chromic acid, stir and dry in a water bath at 70°C to obtain passivated iron-nickel-molybdenum magnetic powder. The mass of chromic acid accounts for 0.6wt% of the total mass of the iron-nickel-molybdenum magnetic powder.

[0033] (3) Dissolve the phenolic resin with absolute ethanol, B 3 o 2 Dissolve the powder in xylene, mix th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com