Flexible piezomagnetic composite material and preparation method thereof

A composite material and flexible technology, applied in the direction of magnetic materials, inorganic material magnetism, magnetic objects, etc., can solve the problems of small interaction force between magnetic powder and rubber, unable to meet the performance requirements, and poor elasticity and mechanical properties of liquid silicone rubber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Preparation and surface modification of ultrafine soft magnetic powder materials.

[0051] Cut a variety of thin strips of soft magnetic materials with good piezoelectric properties into short strips of hundreds of millimeters, place them in a high-temperature furnace under the protection of an inert gas atmosphere such as argon, nitrogen, and heat-treat at 150°C to 600°C for 0.1h ~5h, crushed to obtain millimeter-sized sheets, and then placed in a coordination type containing low-boiling alkanes such as n-hexane, aromatic hydrocarbons such as toluene, and any organic solvent such as acetone and ethanol, which are 0.2% to 1% of the mass of magnetic powder In the ceramic grinding tank of phosphite coupling agent KR-41B (produced by Kenrich Petrochemical Company in the United States), grind with equipment such as planetary mill or stirring mill for 0.5h~48h to make soft magnetic powder slurry with a particle size of 50nm~200μm The slurry is classified by sedimentation and...

Embodiment 2

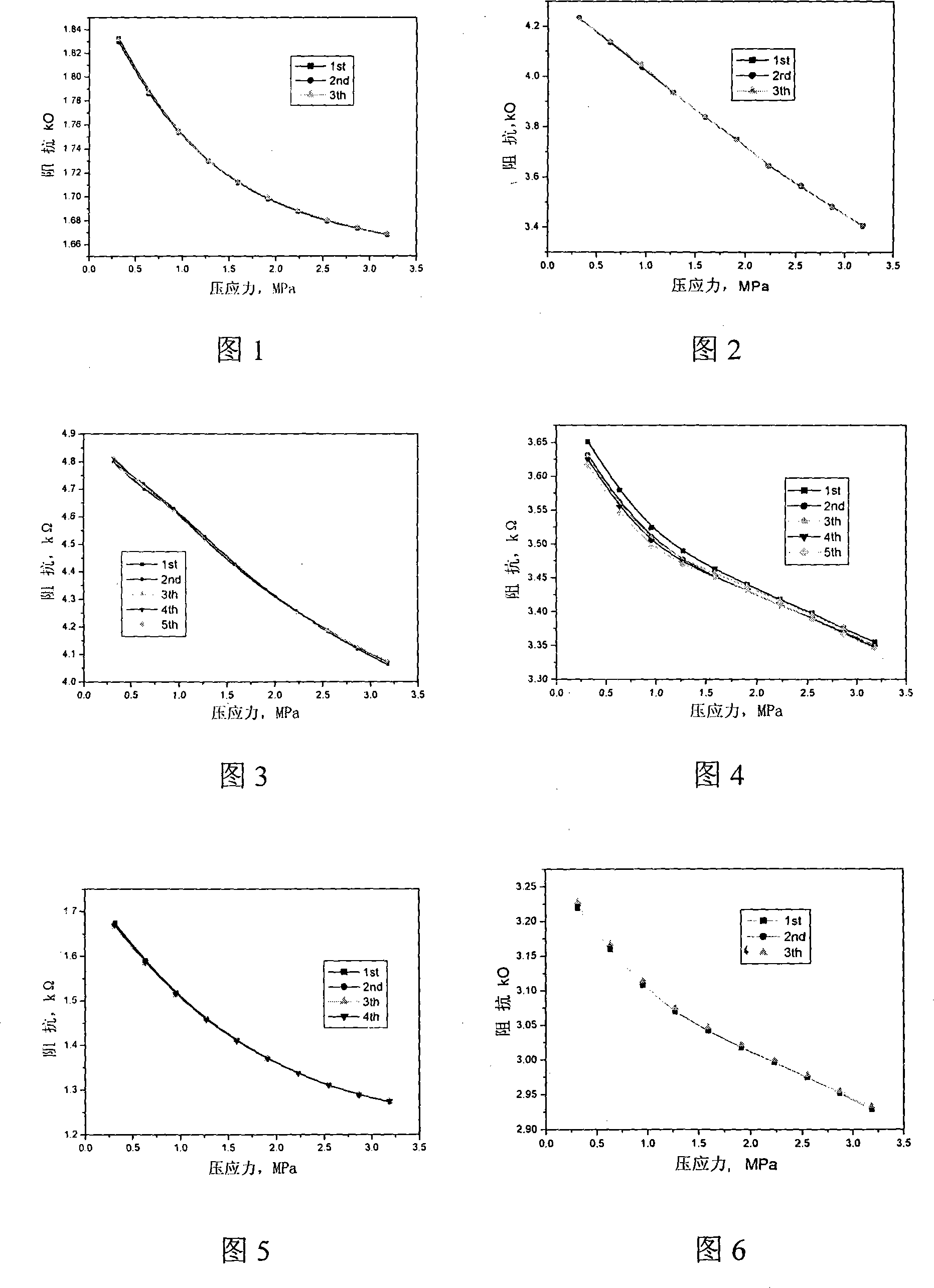

[0053] Preparation of Fe 73.5 Cu 1 Nb 3 Si 13.5 B 9 Amorphous powder / silicone rubber piezomagnetic composite.

[0054] Weigh the ternary regular copolymerized silicone rubber according to the formula in Table 1, and dissolve it in 10 times the mass of n-hexane solvent at room temperature or under the condition of adding ultrasonic waves, and dissolve it for 2d to 7d to obtain silicone rubber-n-hexane Alkane Sol B 1 . Weigh the amount of Fe in the recipe 73.5 Cu 1 Nb 3 Si 13.5 B 9 Amorphous powder added to Sol B 1 In the process, after ultrasonic dispersion for 1h and magnetic stirring for 2h, the amorphous powder was uniformly dispersed in the silicone rubber-n-hexane sol B 1 , to get sol B 2 middle. Sol B was made using a rotary evaporator 2 Fast gel to get Fe 73.5 Cu 1 Nb 3 Si 13.5 B 9 Amorphous powder / silicone rubber gel B 3 , gel B 3 After being placed in the fume hood for 24h ~ 7d, use an open rubber mixing machine to press into thin slices with a th...

Embodiment 3

[0060] Preparation of Fe 73.5 Cu 1 Nb 3 Si 13.5 B 9 Nanocrystalline powder / NR-NdBR composite piezomagnetic material.

[0061] Put natural rubber (NR) and rare earth neodymium butadiene rubber (NdBR) in an internal mixer for 3 minutes according to the formula in Table 2, and first add 1 / 2 of Fe with a particle size of 5 μm 73.5 Cu 1 Nb 3 Si 13.5 B 9 Nanocrystalline powder, after banburying for 3 minutes, add 1 / 4 nanocrystalline powder, add all additives except vulcanization accelerator and sulfur, and banbury for 3 minutes, then add the remaining 1 / 4 nanocrystalline powder and banbury for 5 minutes to produce glue. Thin pass 6 times on the double-roller rubber mixing machine and then unload. After the mixed rubber of the next piece is sealed and stored in a plastic bag for 2 days to 7 days, it is re-milled on the open mill for 5 minutes every two days, and it is thinned and passed 3 times. Add a vulcanization accelerator during the fifth re-milling, knead for 5 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com