Soft magnetic composite organically/inorganically compound insulation coating powdered iron and preparation method thereof

A technology of soft magnetic composite materials and inorganic insulation, applied in the fields of magnetism of inorganic materials, manufacturing of inductors/transformers/magnets, electrical components, etc., can solve problems such as brittleness of the insulating film, complicated preparation process, uneven coating, etc., to achieve Excellent coating effect and mechanical properties, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

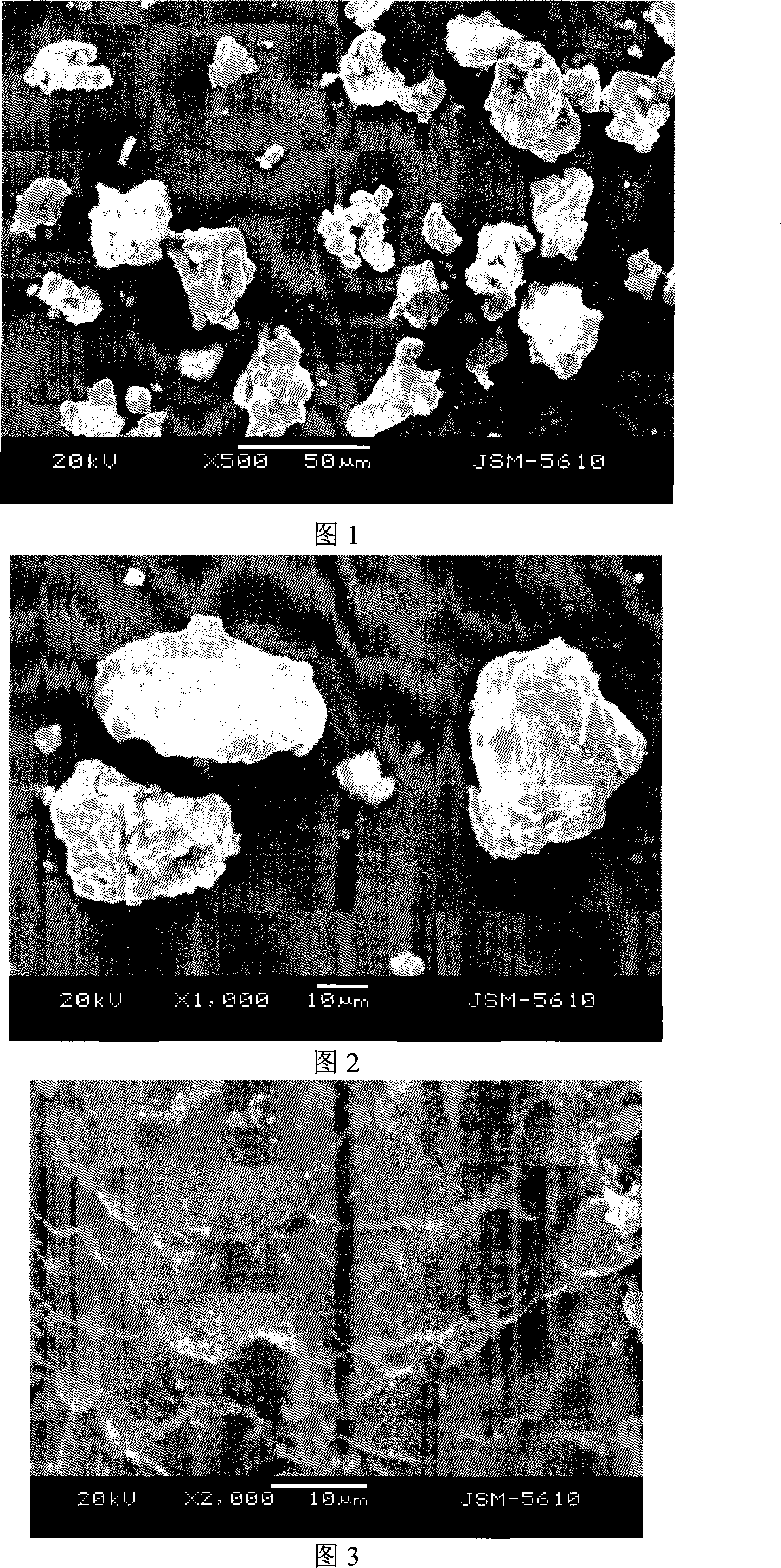

[0030] Mix and stir 13ml of water, 40ml of tetraethyl orthosilicate, and 21ml of ethanol for 30 minutes. During the stirring process, add a few drops of hydrochloric acid (catalyst) to obtain a transparent liquid silica sol, and add epoxy resin (5g of epoxy resin dissolved in 50ml of ethanol) resin solution), continue stirring to form a compatible transparent insulating sol, add 5000g iron powder to the insulating sol, then age at room temperature, after the sol gels, organic / inorganic insulating coated iron powder is obtained soft magnetic composite materials. The scanning electron micrographs of the coated iron powder at different magnifications are shown in Figure 1-3. From Figures 1-3, it can be seen that the surface of iron powder coated with silica and epoxy resin composite prepared by sol-gel process is smooth and uniform without cracks.

Embodiment 2

[0032]Mix 10ml of water, 10ml of tetraethyl orthosilicate, 20ml of methyltrimethylsilane, and 20ml of ethanol and mix and stir for 30 minutes. During the stirring process, add a few drops of hydrochloric acid (catalyst) to obtain a transparent liquid silica sol, add phenolic resin (5g phenolic resin solution dissolved in 50ml ethanol), continue to stir to form a compatible transparent insulating sol, add 5000g iron powder to the insulating sol, and then put it in an oven set at 60°C for aging, the sol After gelation, a soft magnetic composite material of organic / inorganic insulating coated iron powder is obtained.

Embodiment 3

[0034] Mix 15ml of water, 35ml of tetraethyl orthosilicate, and 25ml of ethanol and stir for 30 minutes. During the stirring process, add a few drops of ammonia water (catalyst) to obtain a transparent liquid silica sol. Add 3g of methyl methacrylate and drop a few drops of even Nitrogen initiator, continue to stir to form a compatible transparent insulating sol, add 5000g iron powder to the insulating sol, and then age at room temperature, after the sol gels, an organic / inorganic insulating coated iron powder is obtained soft magnetic composite materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com