Automatic clutch type direct-current brushless motor stator

A brushless DC motor, automatic clutch technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of small adaptability, poor climbing ability and overload ability, large output torque, etc., to achieve simple and compact structure, The effect of improving gradeability and large transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

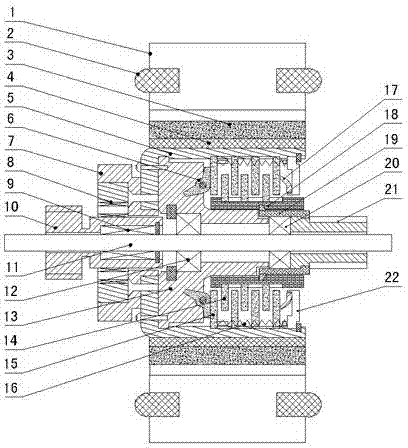

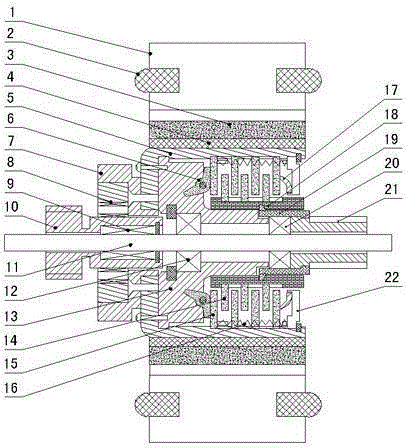

[0012] figure 1 As shown, the invention creates a specific embodiment of the automatic clutch type brushless DC motor rotor, which includes a main shaft 11, an automatic clutch, a rotor magnetic steel 3, and a magnetic isolation sleeve 4. The automatic clutch is rotatably installed on the main shaft 11 Above, the magnetic isolation sleeve 4 is fixed on the outer casing 5 of the automatic clutch, and the rotor magnets 3 are evenly distributed on the magnetic isolation sleeve 4; A one-way device 8 is fixed on the seat 7 , and the low-speed central gear 10 is rotatably arranged on the main shaft 11 through the first bearing 9 , and the inner ring of the one-way device 8 cooperates with the low-speed central gear 10 .

[0013] The automatic clutch includes an outer casing 5, a counterweight fixing seat 13, a centrifugal block 6, an outer friction plate 15, an inner friction plate 14, a bowl-shaped elastic washer 17, an outer ring sleeve 18, an inner ring sleeve 19 and a cover plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com