Centrifugal magnetofluid clutch

A magneto-rheological fluid and clutch technology, applied in the direction of fluid clutches, clutches, mechanical equipment, etc., can solve the problems of short service life, slow response, high transmission torque, etc., and achieve long service life, low power consumption and large transmission torque Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

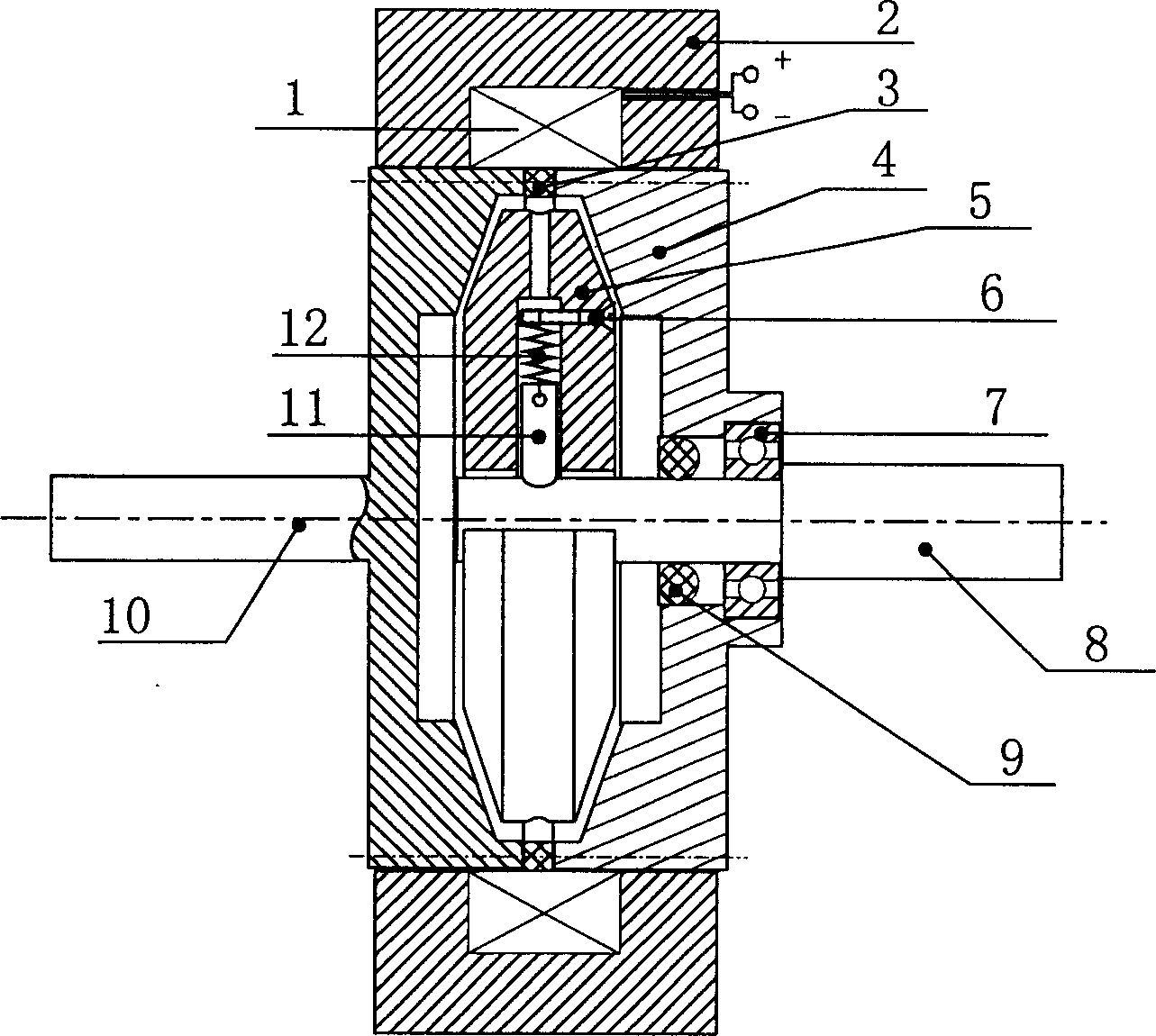

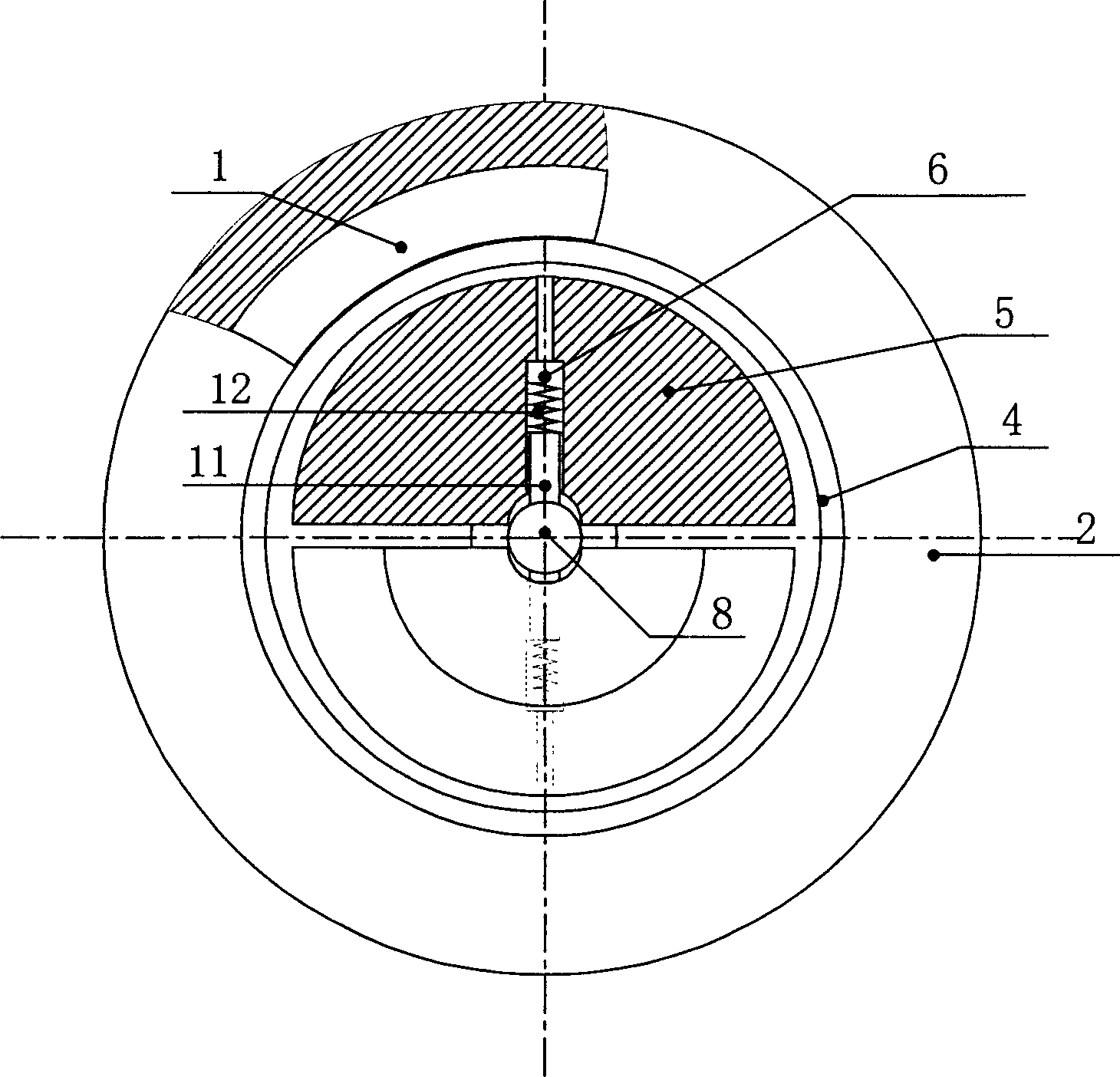

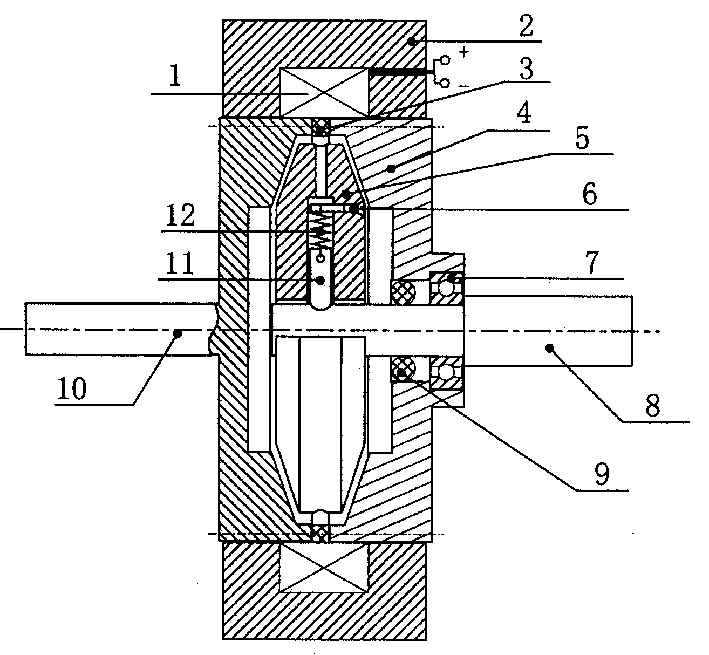

[0014] The embodiment of the present invention is as follows: the outer diameter of the disc-shaped slider is 120 mm, the thickness is 50 mm, the wedge angle is 9.6 degrees, and the mass of each block is about 1.1 kg. Spring preload 50N. The gap between the slider and the slope of the housing is 1.5mm at rest. The shaft diameter is 20mm. The electromagnetic coil is wound with 0.6mm enameled wire, the winding is 800-1000 turns, the inner diameter is 130mm, the resistance is 20Ω, the maximum working current is 2A, and the maximum input power is 80W. The magnetorheological fluid produced by Lord Company of the United States is used. If the traditional method is used, the clutch composed of fixed discs can provide a torque of 50Nm at the same size, 5kW power can be transmitted at a speed of 1000 rpm, and 15kW power can be transmitted at a speed of 3000 rpm. And use the clutch that the dish-shaped slide block that has centrifugal self-pressurizing function of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com