Uniwafer three-disk magnetic rheological clutch

A magnetorheological and clutch technology, applied in fluid clutches, clutches, mechanical equipment, etc., can solve the problems of large clutch volume, inconvenient processing-installation-disassembly, complex structure design, etc., and achieve the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the drawings.

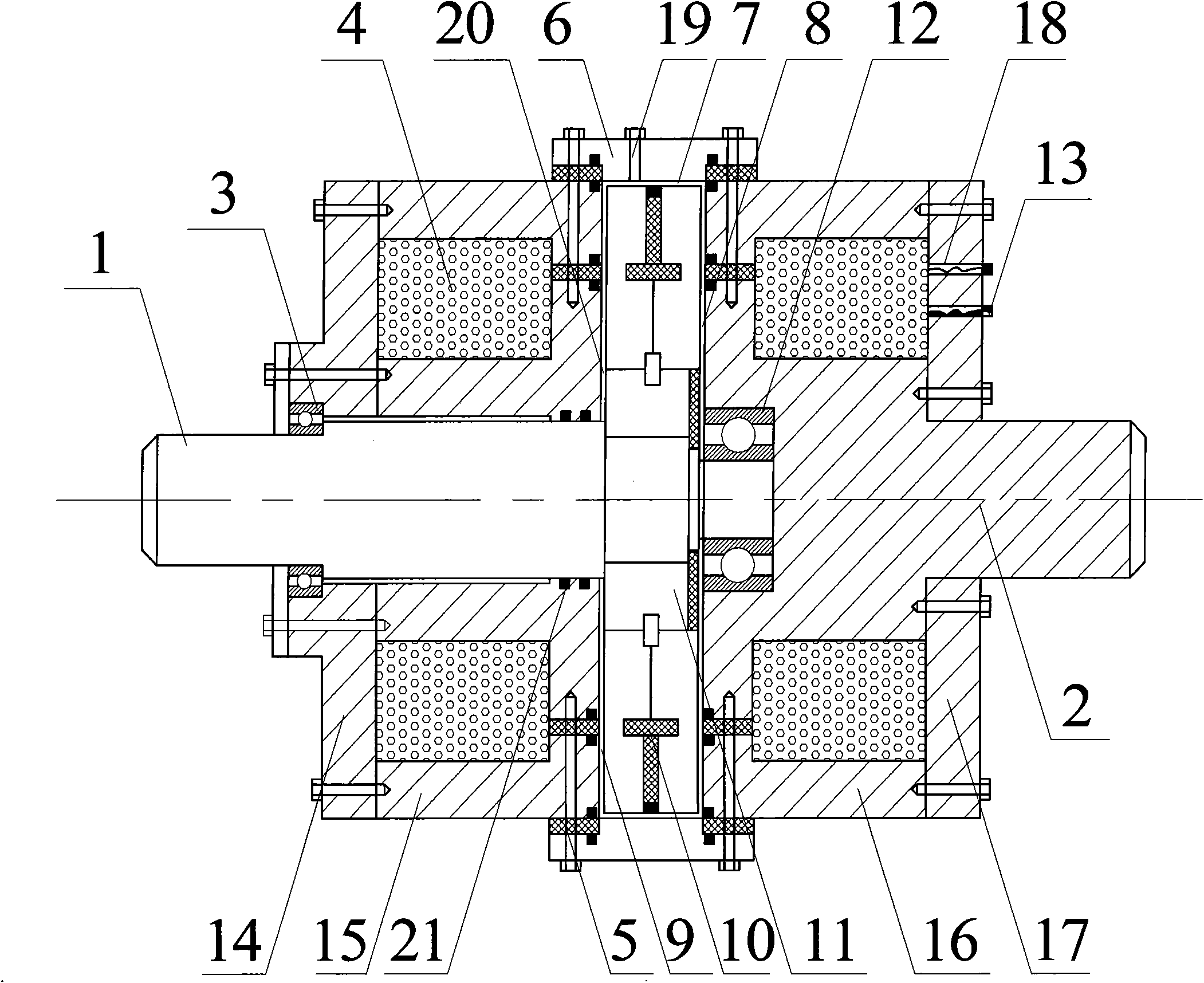

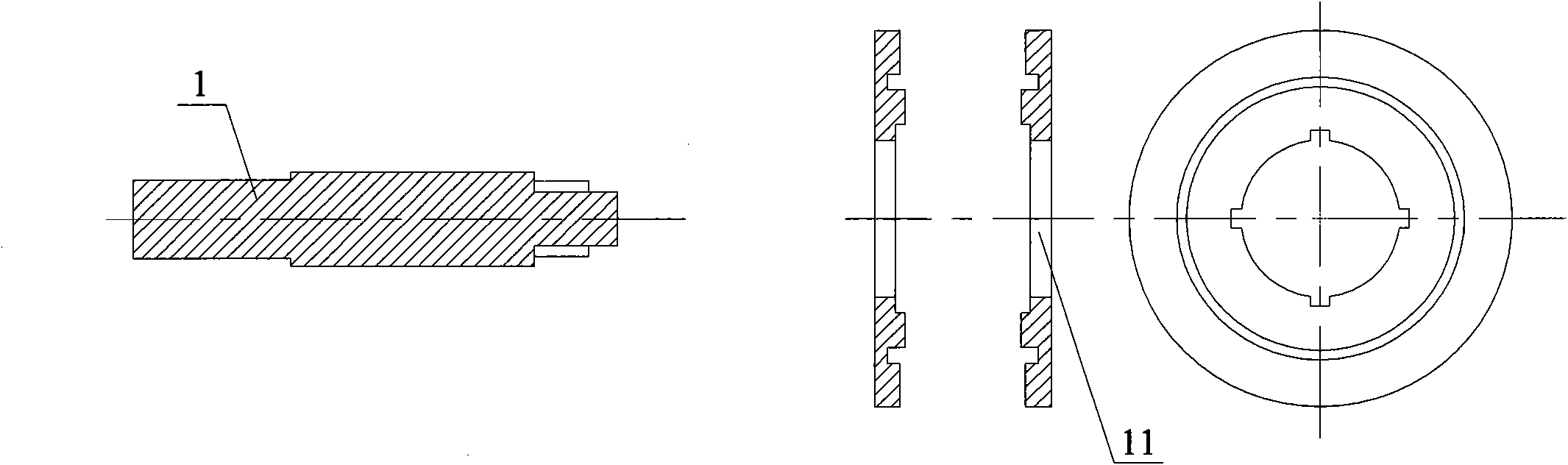

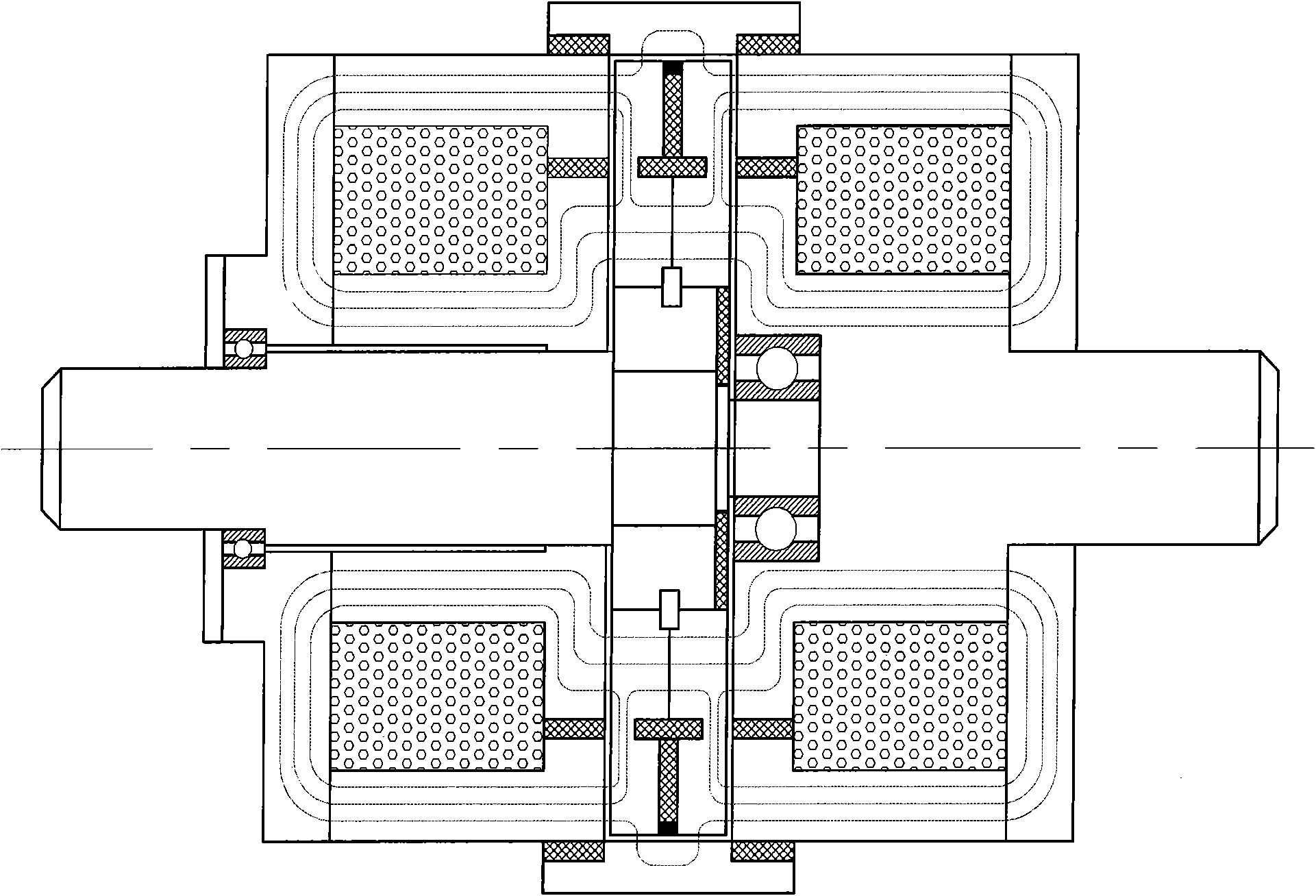

[0028] Such as figure 1 A single-plate three-disc magnetorheological clutch is shown, which includes a driving shaft (1), a driven shaft (2), a driving disc (11), an excitation coil (4), and a magnetorheological left disc channel (9) ), magnetorheological right disc channel (8), magnetorheological ring channel (7), left casing (14), left follower (15), right casing (17), right follower ( 16) Active disc magnetic isolation copper ring (10), follower magnetic isolation copper ring (5), angular contact ball bearing (3), thrust ball bearing (12), magnetorheological fluid (20) and sealing device, It is characterized in that: the driving shaft (1), the driving disk (11), and the driving disk magnetic isolation copper ring (10) are combined into the driving body. The structure of the driving shaft (1) and the driving disk (11) is as follows figure 2 As shown; the driving shaft (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com