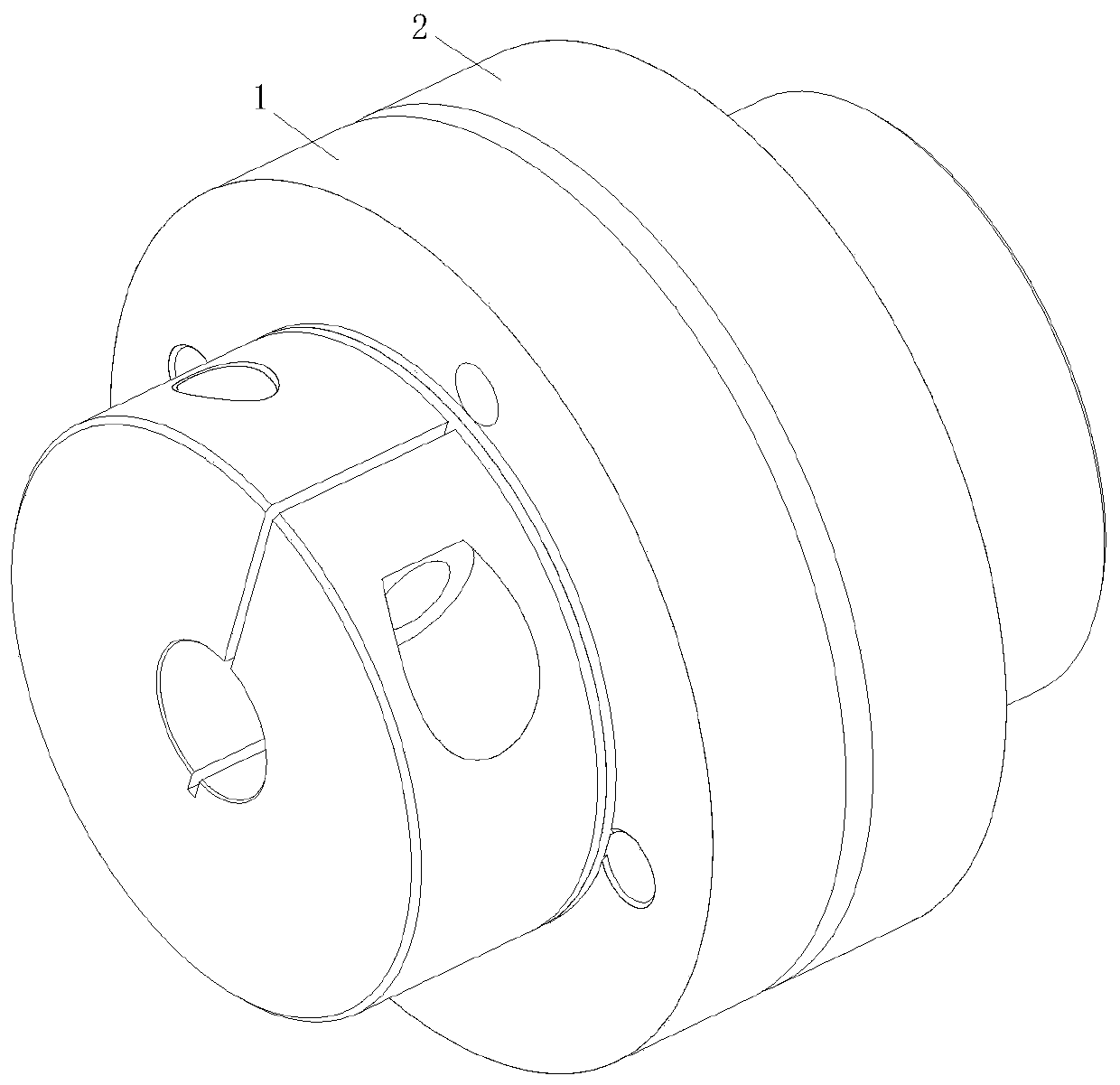

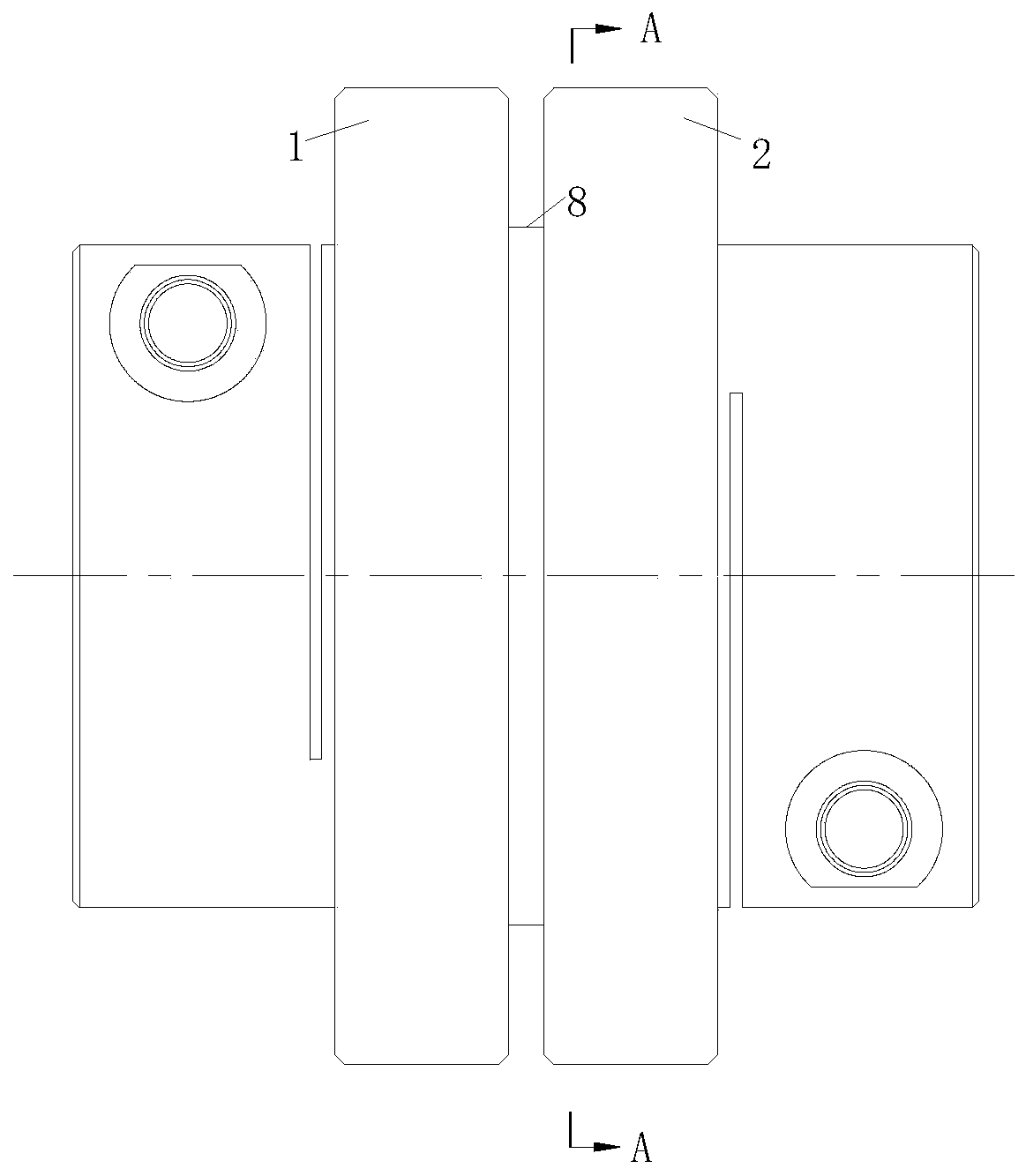

Coupling

A coupling and half-coupling technology, applied in couplings, elastic couplings, clutches, etc., can solve the problems of prime mover damage, short coupling life, high impact force transmission requirements, etc. The effect of reducing the transmission of vibration, improving the lifespan, and protecting the safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

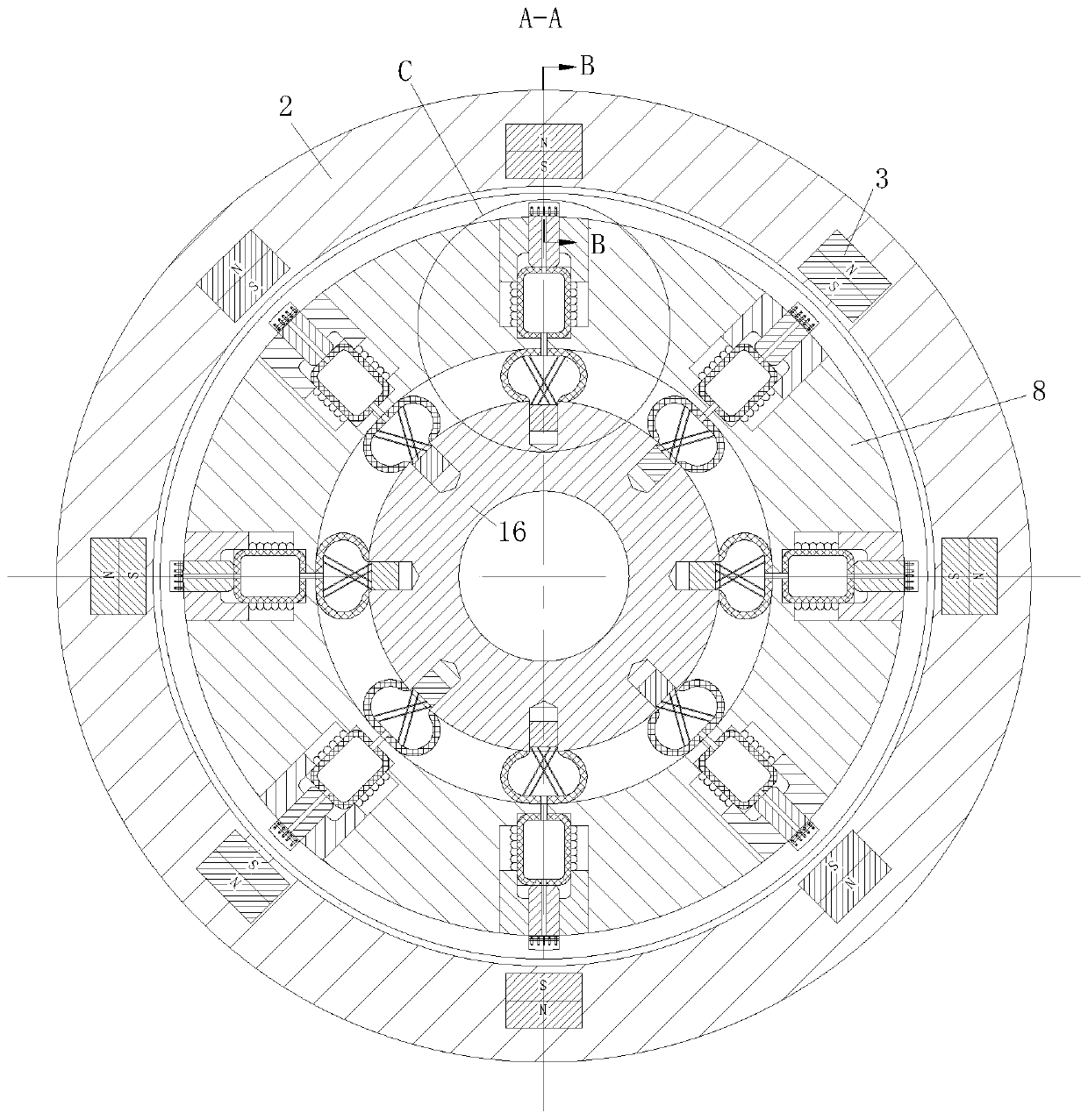

[0023] As an embodiment of the present invention, the slider 6 is provided with a V-shaped groove 11 at one end close to the groove 7; the annular side wall of the groove 7 is provided with an annular wedge 12 matching with the V-shaped groove 11; Through the cooperation of the V-shaped groove 11 and the annular wedge 12, the friction area is increased, and the transmission torque is further increased. At the same time, the annular wedge 12 can remove wear residues; through the cooperation of the V-shaped groove 11 and the annular wedge 12, the frictional contact can be increased area, to further increase the transmission torque of the coupling, and the larger frictional contact area can also reduce the wear of the slider 6 and increase the life of the slider 6; Quickly discharge the residue generated by the friction between the V-shaped groove 11 and the annular wedge 12, reducing the impact of the residue on the normal operation of the coupling.

[0024] As an embodiment of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com