Auxiliary transmission mechanism for fabric roll of fabric spreading machine

A technology of auxiliary transmission and spreading machine, applied in the field of machinery, can solve problems such as insufficient motor power, insufficient roller friction, and installation space is not allowed, so as to achieve improved versatility, good clamping effect, and easy tension-free release Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

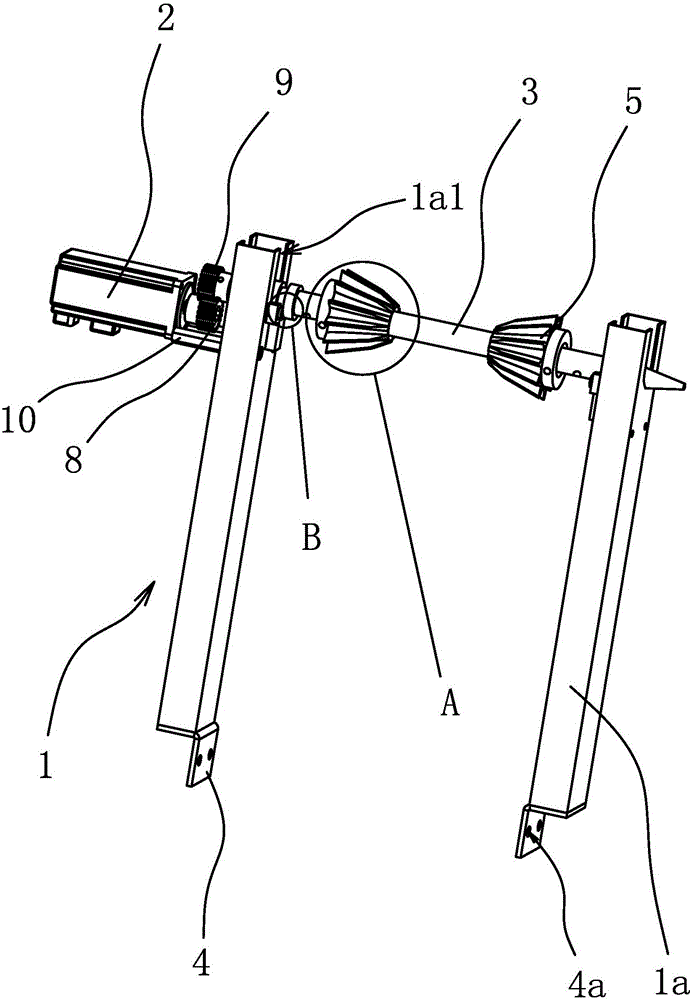

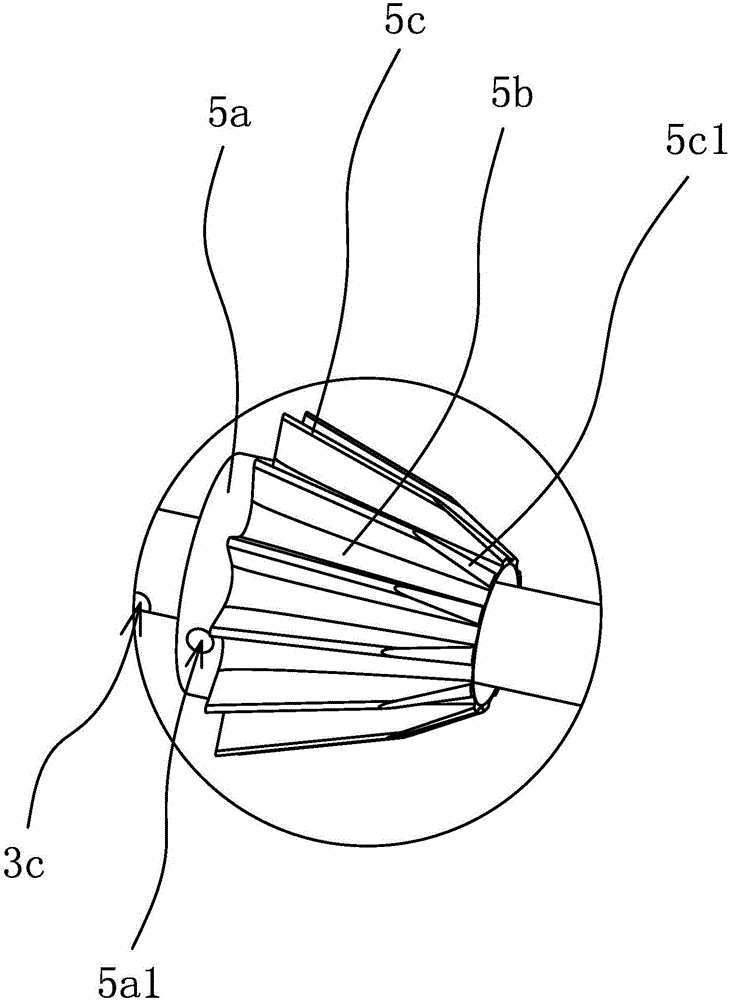

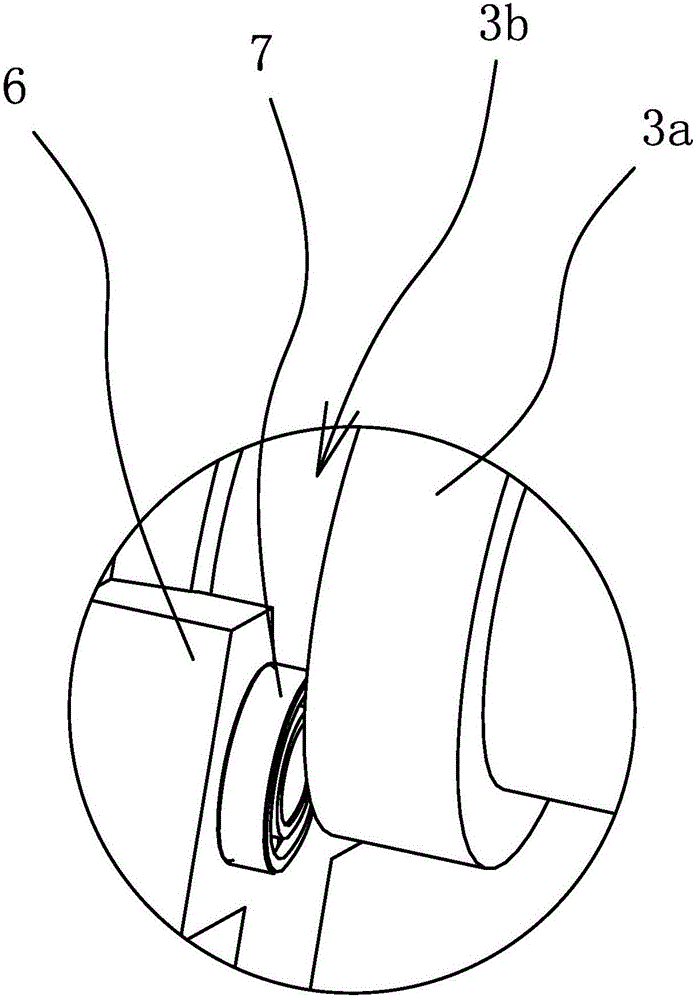

[0023] The cloth spreading machine includes a main frame and a cloth unwinding mechanism arranged on the main frame, and the cloth unwinding mechanism has a cloth unwinding motor. Such as Figure 1-3 As shown, the cloth roll auxiliary transmission mechanism of the spreading machine includes a support frame 1, a driving motor 2 and a transmission shaft 3, and the bottom of the support frame 1 has a mounting seat.

[0024] Such as figure 1As shown, the support frame 1 includes two support columns 1a, the mounting seat is an installation angle iron 4, each support column 1a is correspondingly provided with an installation angle iron 4 and the two installation angle irons 4 are arranged oppositely, the bottom surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com