In-wheel motor drive unit

A driving device and motor technology, applied in the direction of gear transmission, power device, transmission, etc., can solve the problems of increase in weight and size of the reducer, inappropriateness, and difficulty in compacting, and achieve the effect of large transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

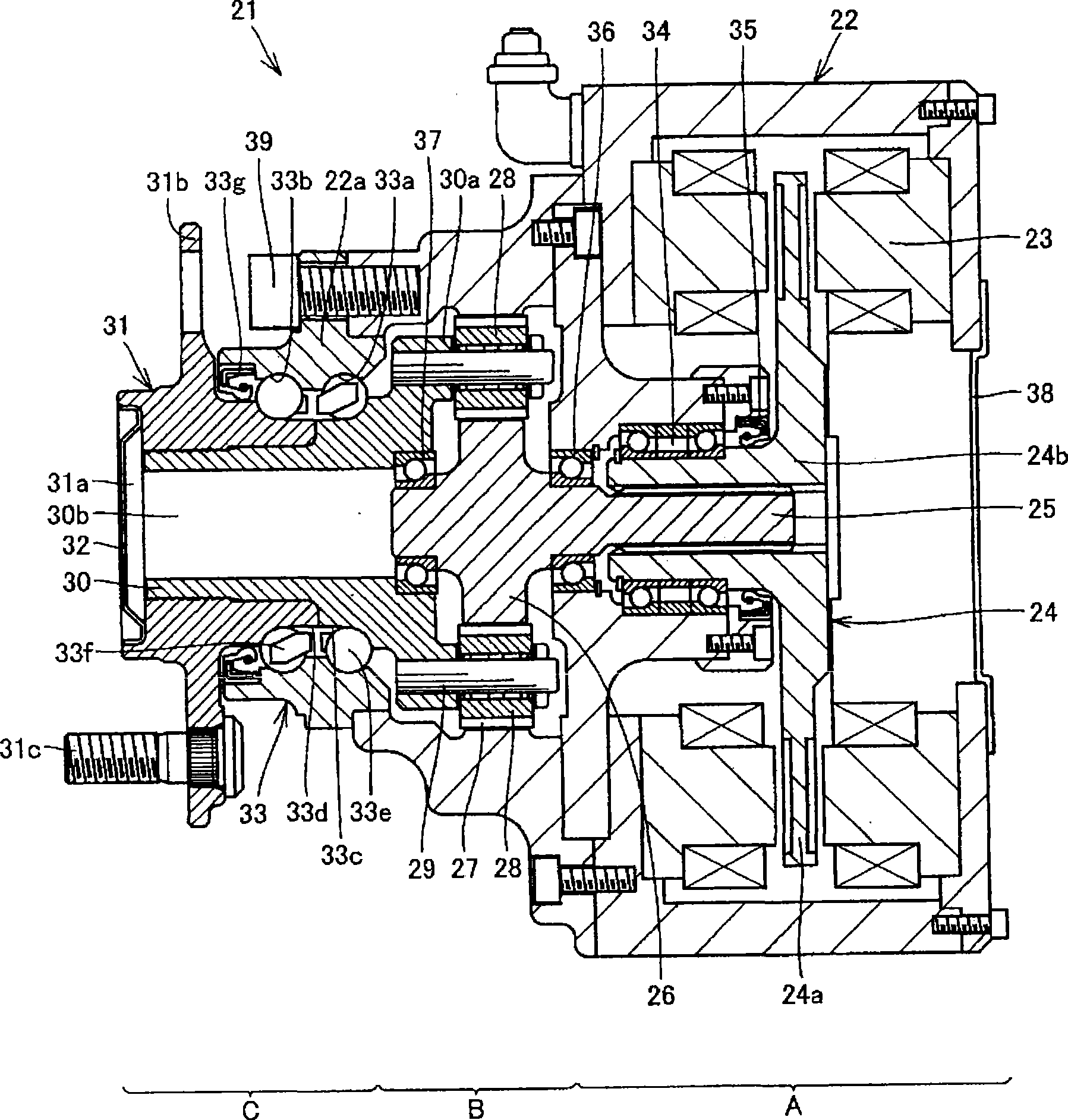

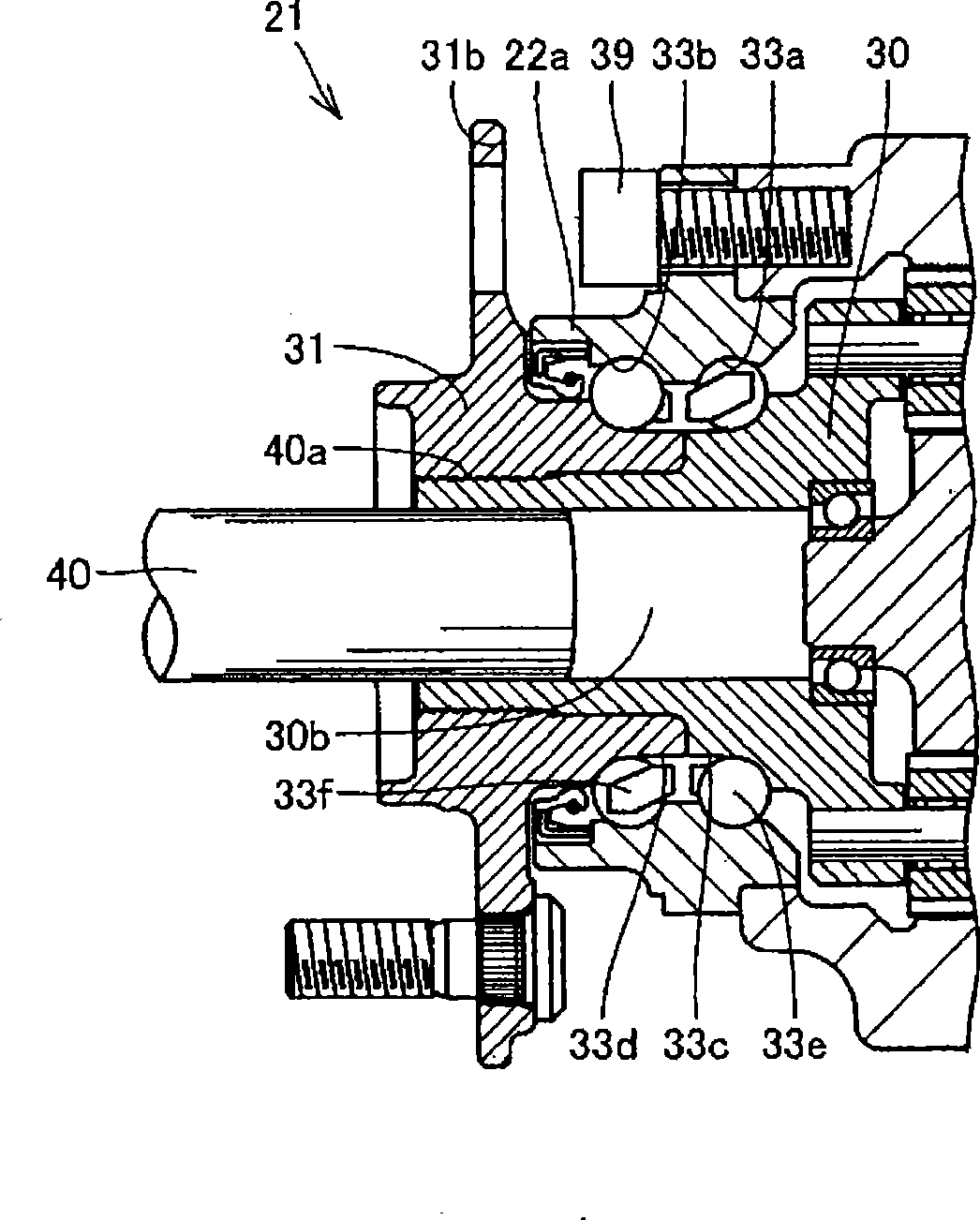

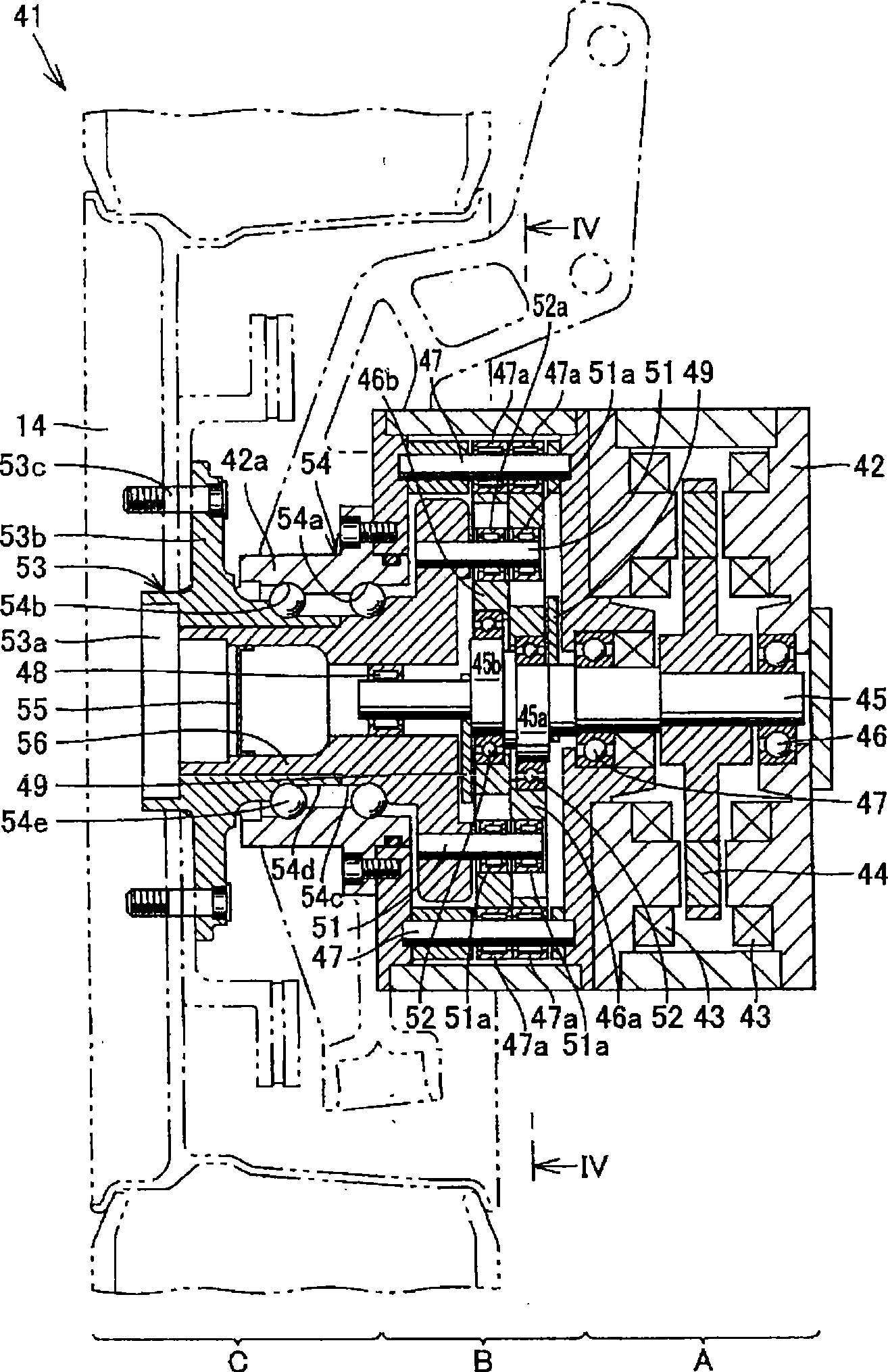

[0042] Referring to Figure 11 and Figure 12 An electric vehicle 11 including an in-wheel motor drive unit (in-wheel motor drive unit) according to an embodiment of the present invention will be described. In addition, FIG. 11 is a top view of an electric vehicle 11, Figure 12 It is the figure which looked at the electric vehicle 11 from the rear.

[0043] Referring to Figure 11 and Figure 12 An electric vehicle 11 has a chassis 12, front wheels 13 as guide wheels, rear wheels 14 as drive wheels, and in-wheel motor drive devices 15 that transmit driving force to the left and right rear wheels 14, respectively. rear wheel 14 as Figure 12 As shown, it is accommodated inside the wheel housing 12a of the chassis 12, and is fixed to the lower part of the chassis 12 via a suspension device (suspension) 12b.

[0044] The suspension device 12b supports the rear wheels 14 by suspension arms extending left and right, and absorbs vibrations received by the rear wheels 14 from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com