Three-roller coal miner applicable to coal seam with thickness of 7-10m and mining method

A shearer and three-drum technology, applied in cutting machinery, ground mining, earth-moving drilling, etc., can solve the problems of incompatibility, complex mining process, and inability to exert large mining height and fully mechanized mining, and achieve enhanced interchangeability. , to ensure the effect of safe and efficient mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

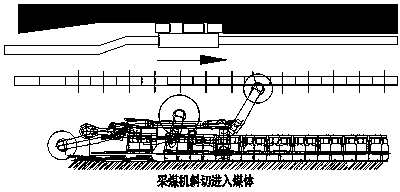

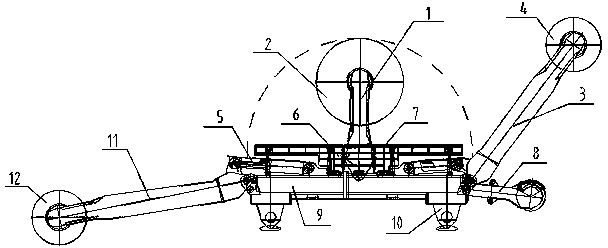

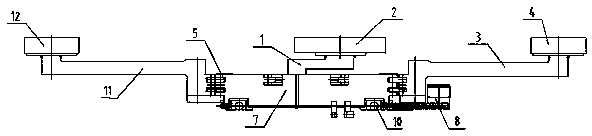

[0035] figure 1 , figure 2 Shows that the present invention is suitable for a three-drum coal shearer suitable for 7-10m hard and thick coal seams, including a short middle rocker arm 1, a middle large-diameter drum 2, a first end long rocker arm 3, a second end long rocker arm 11, The upper small-diameter drum 4 on the long rocker arm 3 at the first end, the lower small-diameter drum 12 on the long rocker arm 11 at the second end, the height adjustment cylinder 5, the electrical control system 6, the coal guard 7, and the crushing device 8 , Bottom bracket 9, walking part 10, each of the left and right ends of the fuselage is provided with a height adjustment cylinder 5, one end of the two height adjustment cylinders 5 is connected with the fuselage, and the other end is connected with the first end of the long rocker arm 3 and the second end. The long end rocker arm 11 is connected, and the above-mentioned rocker arm is swung through the raising cylinder 5 to realize the heig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com