Five-bit spiral-drill coal mining device convenient for switching drilling rods

A coal mining device and auger technology, applied in the direction of earth drilling, driving devices, cutting machinery, etc., can solve the problems of high labor intensity of workers, waste of coal resources, and difficulty in mining extremely thin coal seams, so as to save the replacement of drill pipes time, save manpower and material resources, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

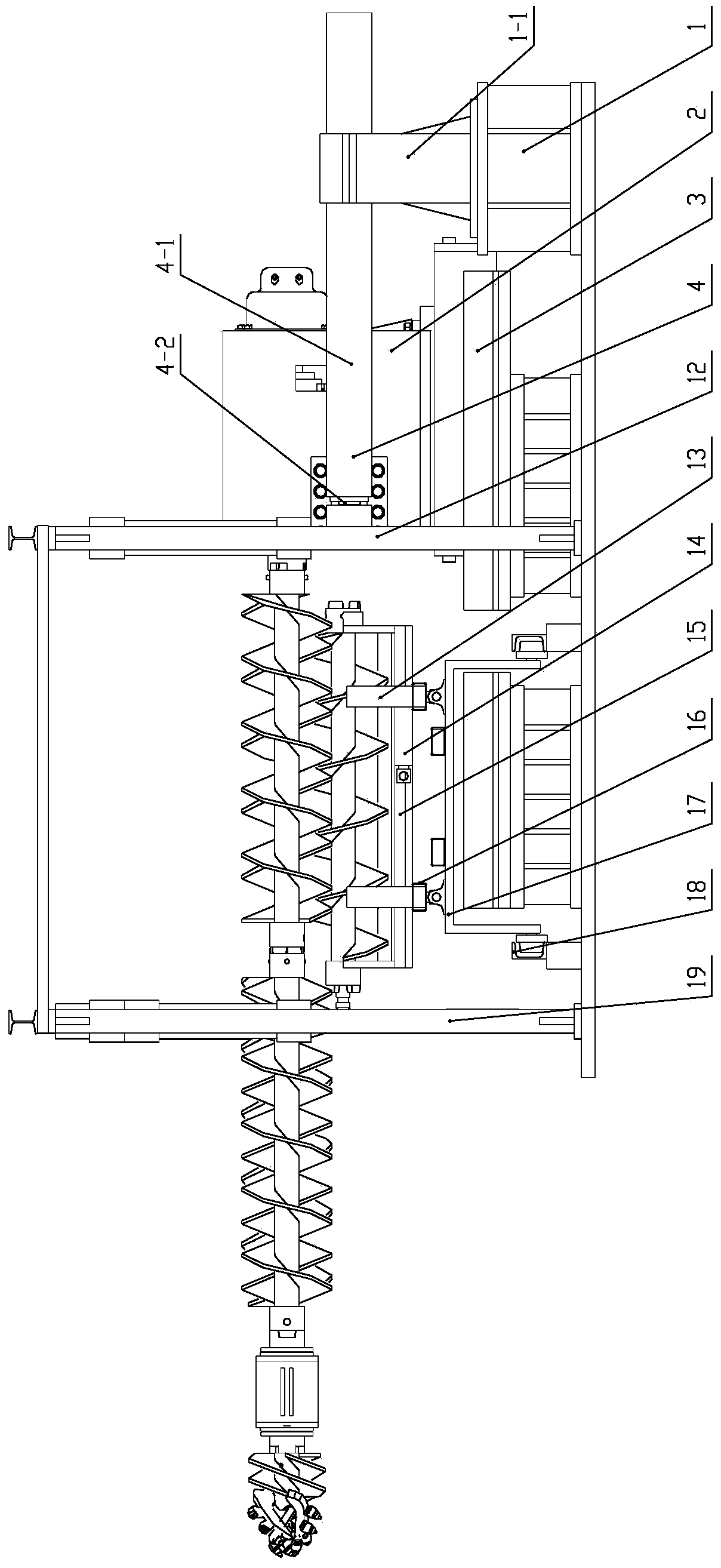

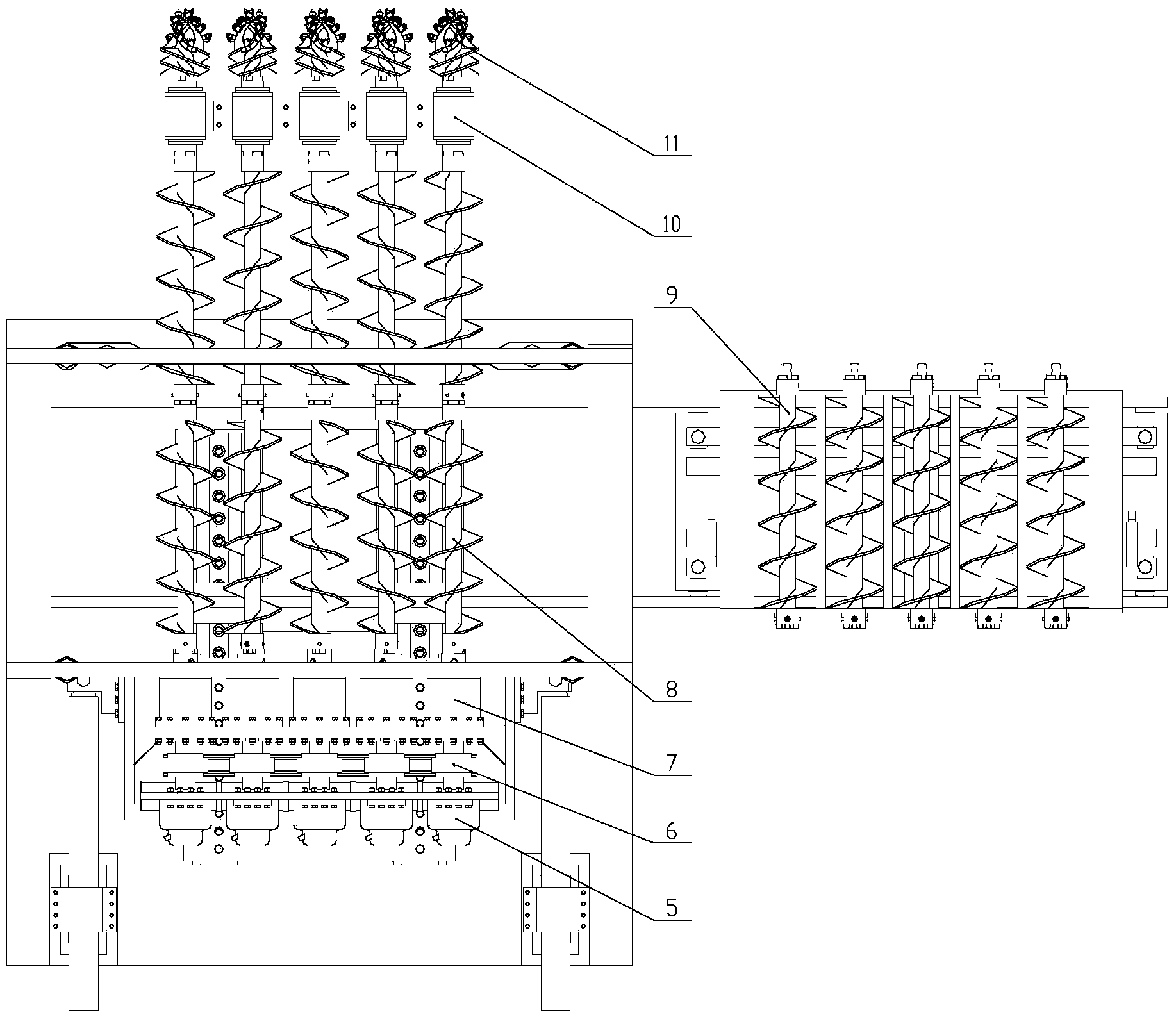

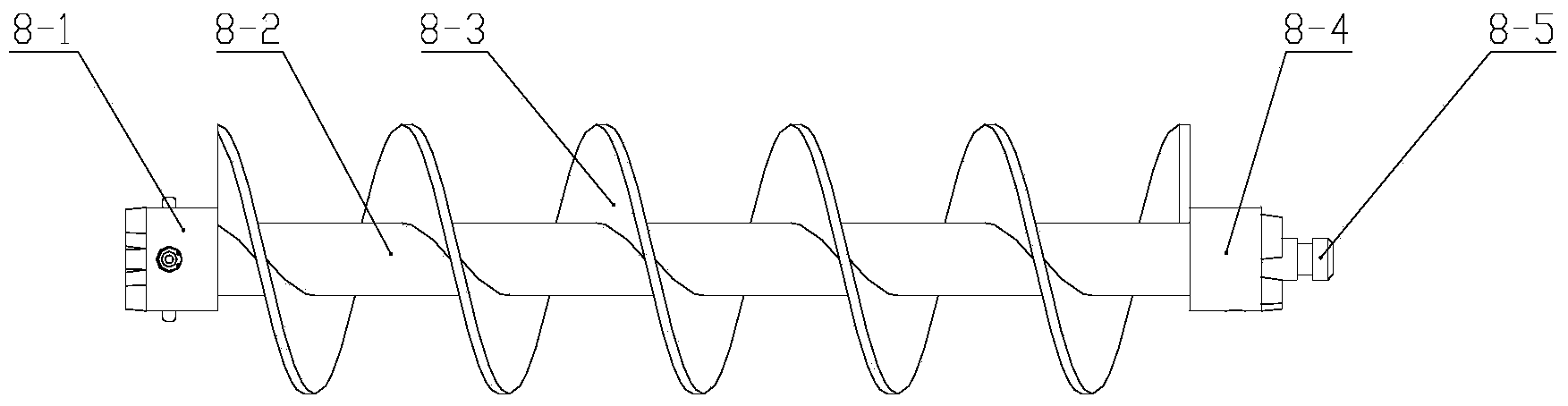

[0033] Such as figure 1 , figure 2 Shown is a five-drill-bit auger coal mining device that facilitates the exchange of drill pipes, including a bracket 1, a mobile frame 2, a propulsion guide rail 3, a hydraulic propulsion cylinder 4, an auger bit assembly, a rear-end holding device 12, and a lifting hydraulic pressure Cylinder 13, auxiliary hydraulic cylinder 14, drill pipe support frame 15, drill pipe elevating frame 16, drill pipe bottom bracket 17, drill guide rail 18, auxiliary guide rail and front-end clamping device 19; the drill pipe support frame 15 is used for Install the drill pipe 9 to be changed;

[0034] The bracket 1 is provided with a propulsion cylinder mounting seat 1-1; the propulsion guide rail 3 includes a propulsion track and a propulsion slider, and the propulsion track and the propulsion slider are respectively consolidated with the bracket 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com