Drum turning mechanism for continuous miners and longwall shearers

a technology of drum turning mechanism and longwall shearer, which is applied in the direction of pedestrian/occupant safety arrangement, driving means, vehicular safety arrangement, etc., can solve the problems of unsatisfactory machine service life, unfavorable customer service, and affecting the cutting performance of mining machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

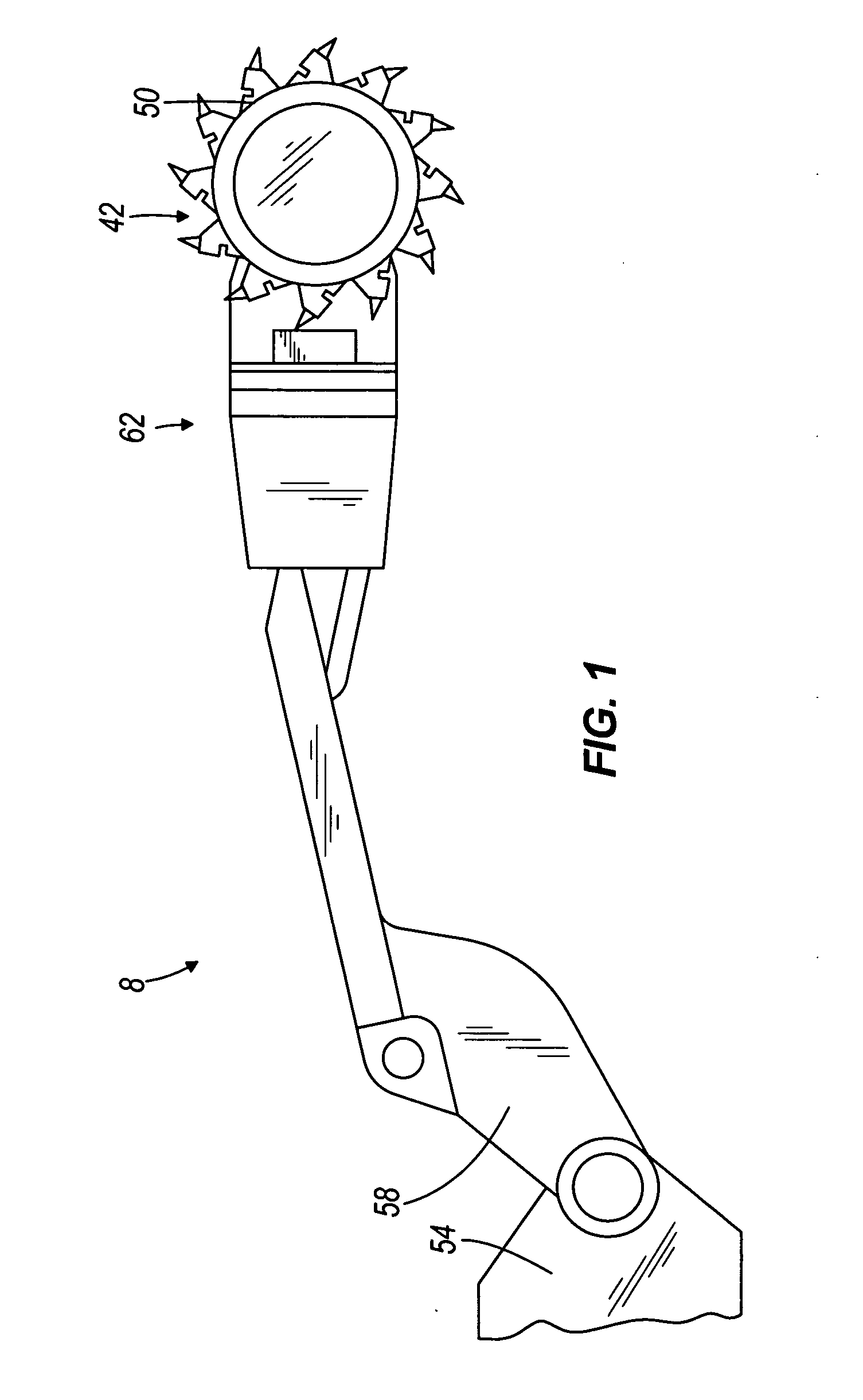

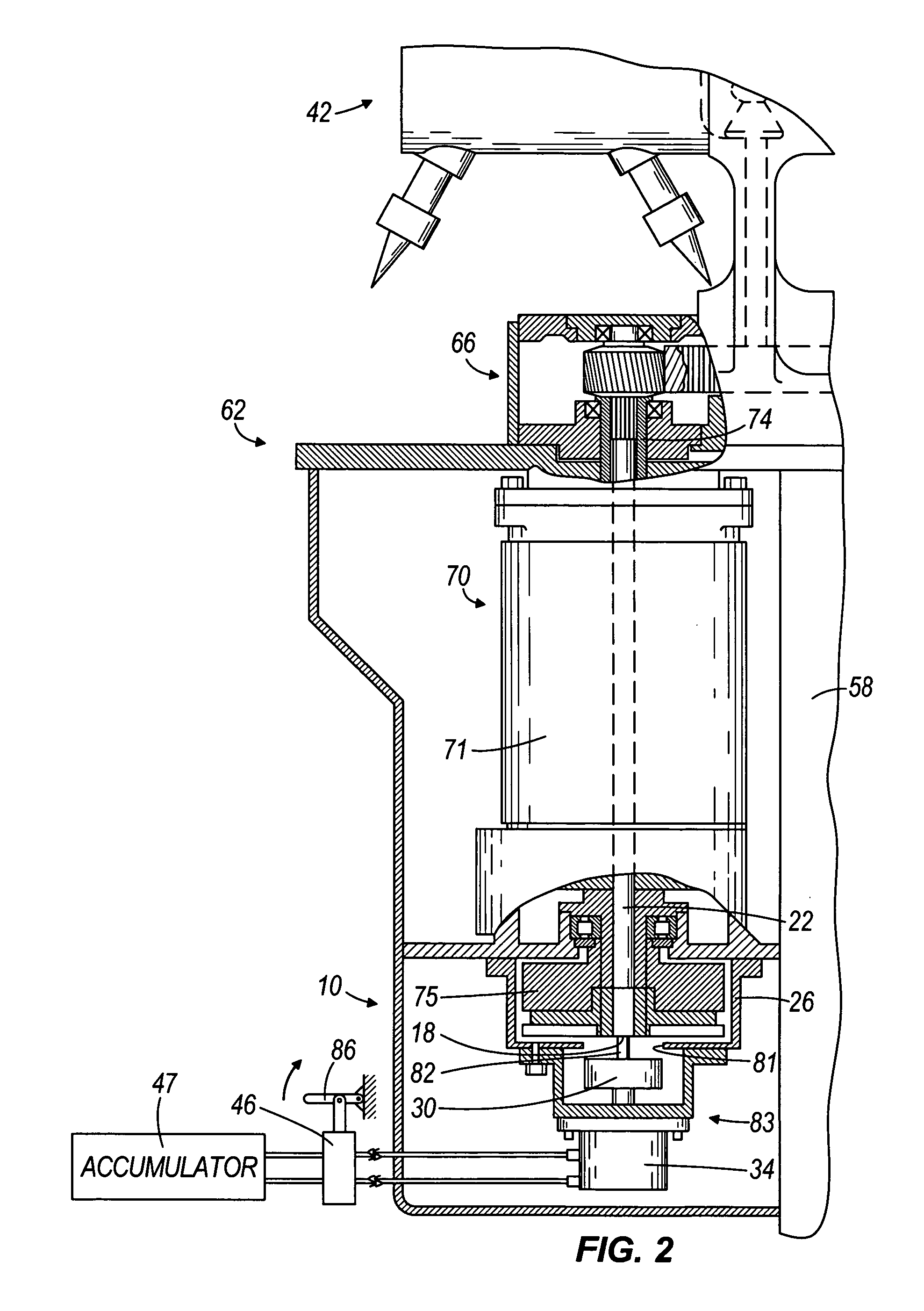

[0022] An embodiment of the invention is illustrated in FIGS. 1 and 2. More particularly, as shown in FIG. 1, the invention comprises a mining machine 8 (only part of which is shown) including a cutting drum 42, bits 50 mounted on the cutting drum 42, a base 54, and a boom 58 extending between the base 54 and the cutting drum 42 for mounting the drum 42 on the base 54. The mining machine 8 also includes a primary cutting drum turning mechanism 62 attached (indirectly in the illustrated embodiment) to the boom 58 and in driving connection with the cutting drum 42 for causing cutting movement of the cutting drum 42 at a cutting drum cutting speed.

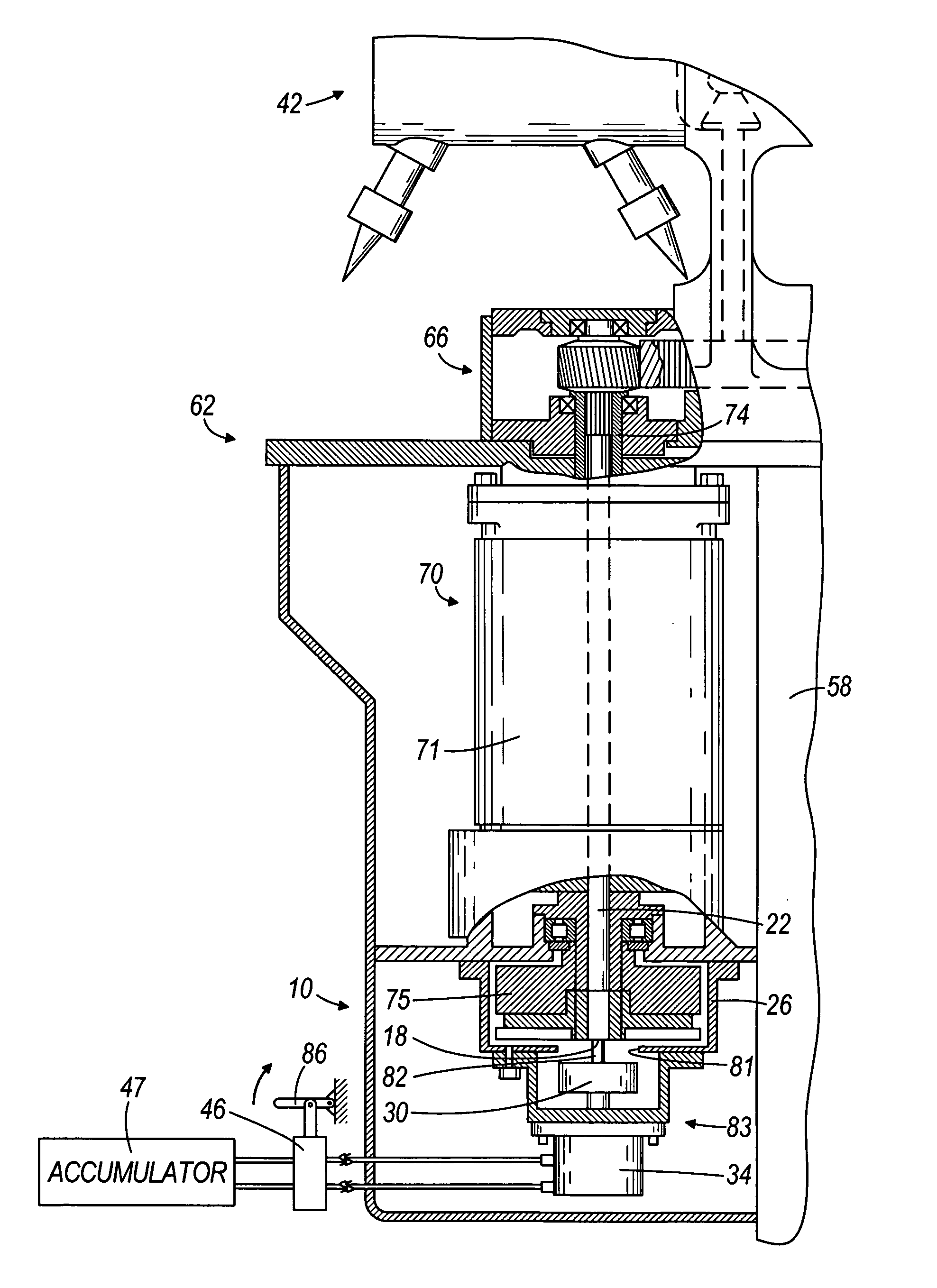

[0023] As illustrated in FIG. 2, the primary cutting drum turning mechanism 62 includes a gear case 66 attached to the boom 58, and a cutter motor 70. The cutter motor 70 is attached at one end to the gear case 66 and is in driving connection with the cutting drum 42 through the gear case 66.

[0024] The motor 70 further includes a motor hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com