Cantilever type electric traction coal cutter

An electric traction and shearer technology, applied in the field of coal mining machinery and cantilever electric traction shearer, can solve the problems of poor structural stability of the whole machine, high failure rate, large machine surface height, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

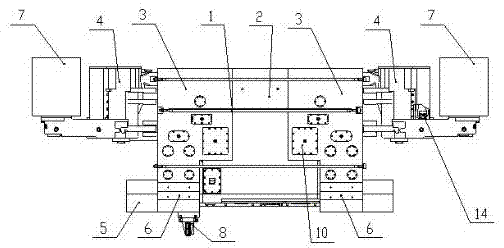

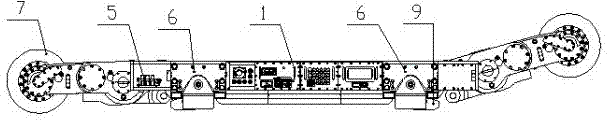

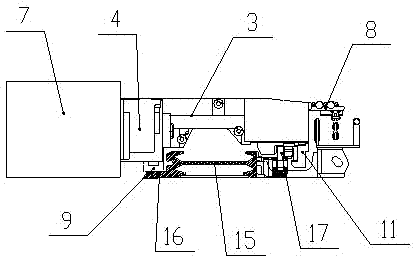

[0013] like Figure 1 to Figure 4 As shown, a cantilever type electric traction shearer includes a fuselage 1, a cutting part 4, a hydraulic device 5 and a tow cable device 8, wherein the fuselage is arranged in three sections horizontally, and is composed of an electric control box 2, a traction Box 3 and walking part 6 are formed, and electric control box 2 top view structure is T-shaped, and hand console is fixed on its vertical front, and electrical button and isolating switch handle are arranged on the hand console. The left and right traction boxes 3 have the same structure and are left and right symmetrical. They are respectively fixed with the same left and right running parts 6 by bolts, and are connected to the left and right sides of the electric control box 2, and are fixed as a whole by long screws. The left and right traction boxes 3 are respectively provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com