Middle trough with pin rails on two sides

A technology of side pin and pin rail, which is used in earthwork drilling, transportation and packaging, underground transportation, etc., can solve problems such as low work efficiency, large walking resistance, and no jamming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

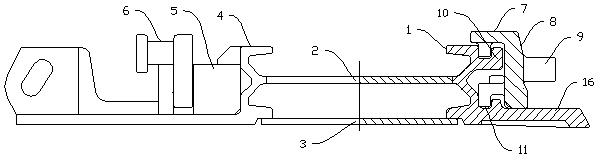

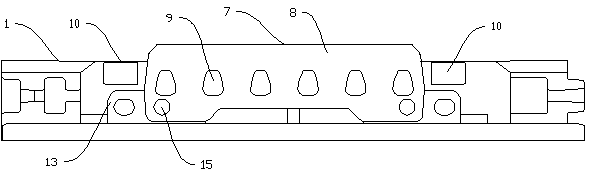

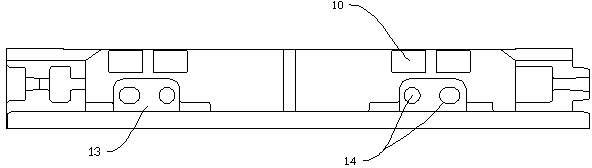

[0016] by figure 1 with figure 2 As shown, the middle groove of the double-sided pin rail includes a shovel plate slot 1, a middle plate 2, a bottom plate 3, and a baffle plate slot 4 that are welded together. The shovel plate 16 and the shovel plate slot 1 are integrated, and the shovel plate 16 Located at the outer side of the lower end of the shovel shovel ledge 1, a shovel body is composed of the shovel shovel ledge 1, the middle plate 2, the bottom plate 3, the baffle ledge 4 and the shovel plate 16 connected to the shovel shovel groove 1 as an integral type. A rail seat 5 is provided on the outer side of the baffle groove side 4, a pin rail 6 is connected to the rail seat 5, and a push ear is connected to the outer side of the baffle groove side 4. An offset pin rail 7 is provided on the outer side of the shovel shovel bank 1, and a track formed by a plurality of offset pin rails 7 arranged along the groove direction on the outside of the shovel shovel bank 1 is a support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com