Traction box for thin coal seam coal cutter

A technology for a shearer and a traction box, which is applied in the field of traction boxes, can solve the problems of increased thickness of the fuselage, poor adaptability for mining thin coal seams, and high height of the shearer surface, and achieves reduced volume, compact structure, and shortened shafts. effect on length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

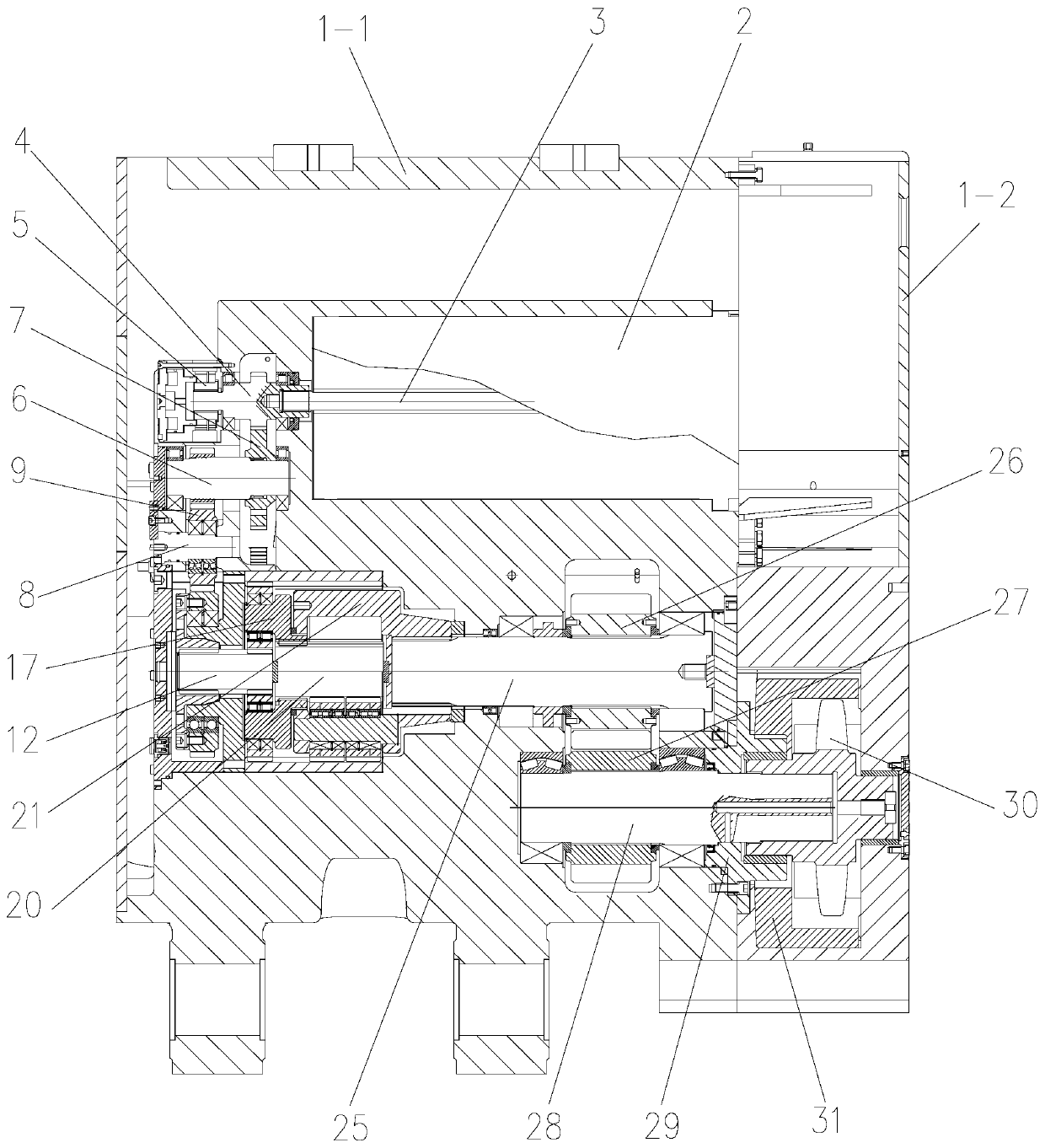

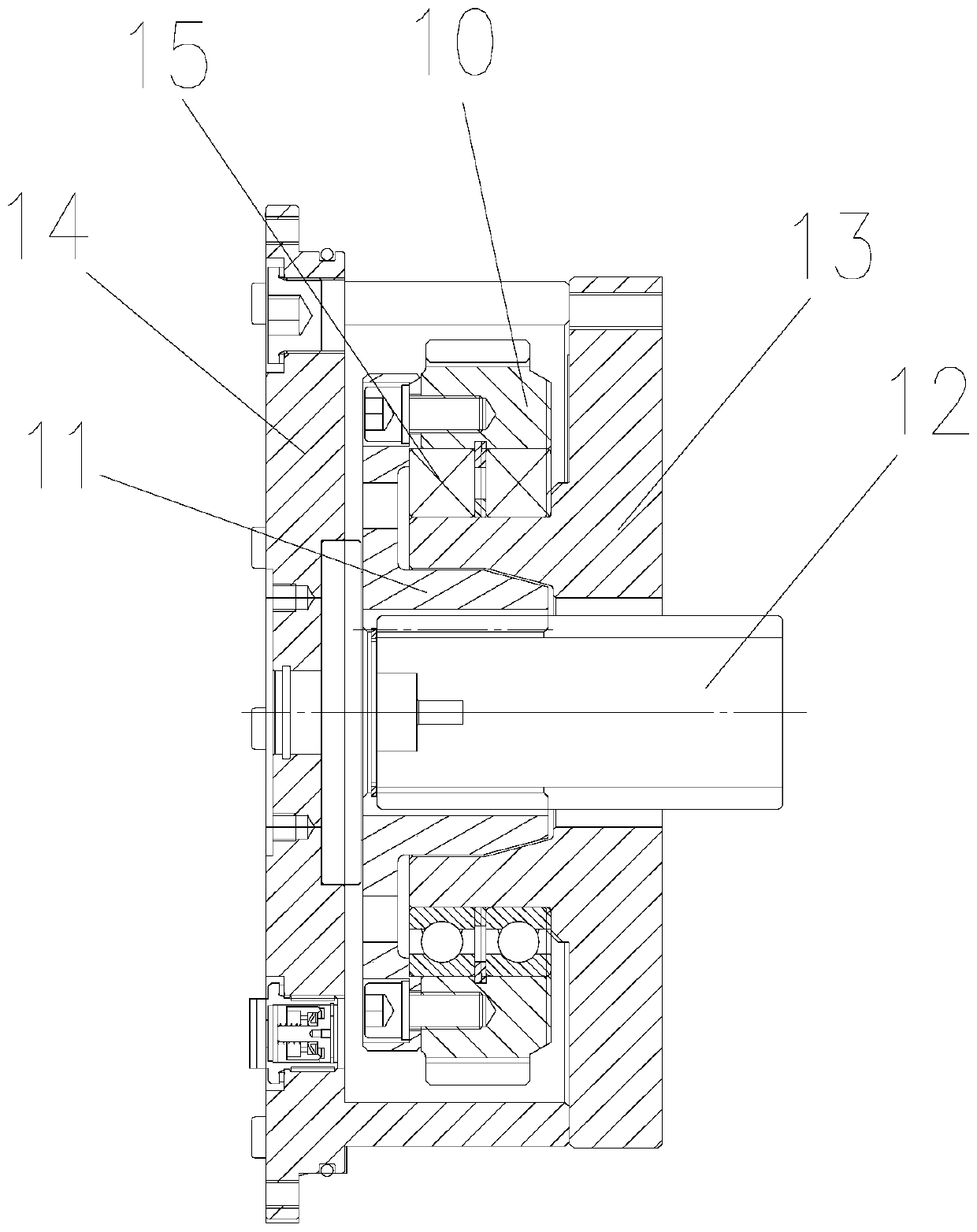

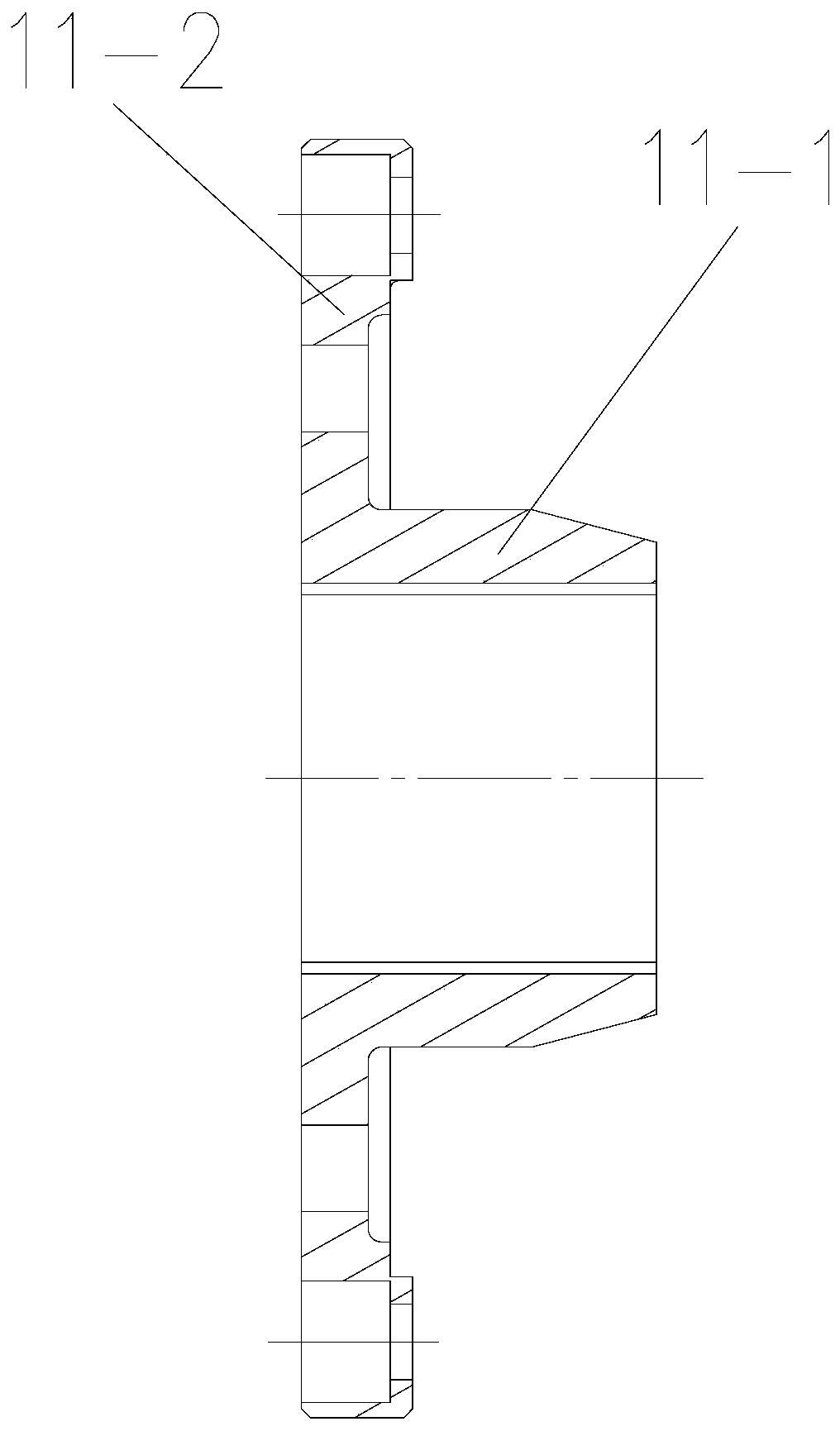

[0047] Such as figure 1 , figure 2 and Figure 5 As shown, the present invention includes a box body, a drive motor 2 arranged inside the box body, and a traction transmission mechanism connected to the drive motor 2. The output end of the traction transmission mechanism is connected with a two-stage planetary reduction mechanism, so The output end of the two-stage planetary reduction mechanism is connected with a rack wheel transmission mechanism, and a rack wheel assembly is installed on the rack wheel transmission mechanism, and the traction transmission mechanism includes a traction flexible shaft 3 connected with the drive motor 2 , the first gear shaft assembly fixedly connected with the traction flexible shaft 3 and the second gear shaft assembly connected with the transmission of the first gear shaft assembly, and the idler shaft assembly and the idler shaft assembly connected with the transmission of the second gear shaft assembly A first spline shaft assembly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com