Hydraulically-driven thin coal seam coal mining machine

A technology for coal shearer and thin coal seam, which is applied to driving devices, cutting machinery, ground mining, etc., can solve the problems of constant rotation speed of the drum of the cutting part, poor mining efficiency, low mining efficiency, etc., and achieve cutting efficiency. High, simple structure, reducing the effect of failure points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail through the accompanying drawings and specific embodiments below.

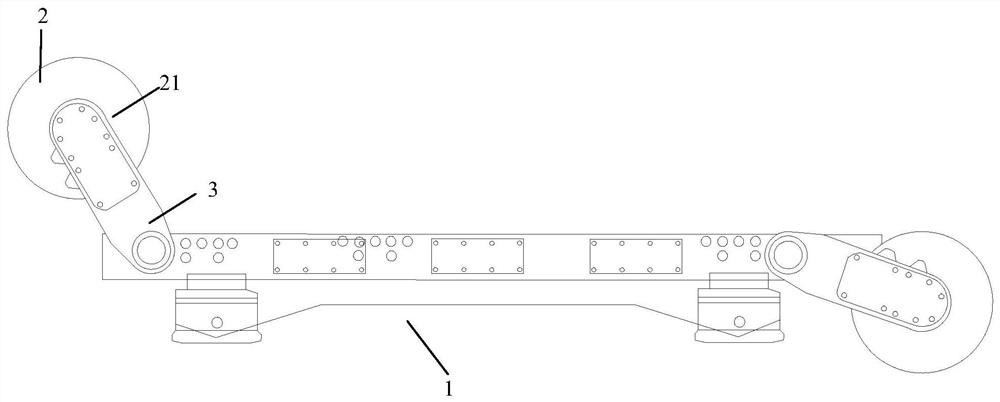

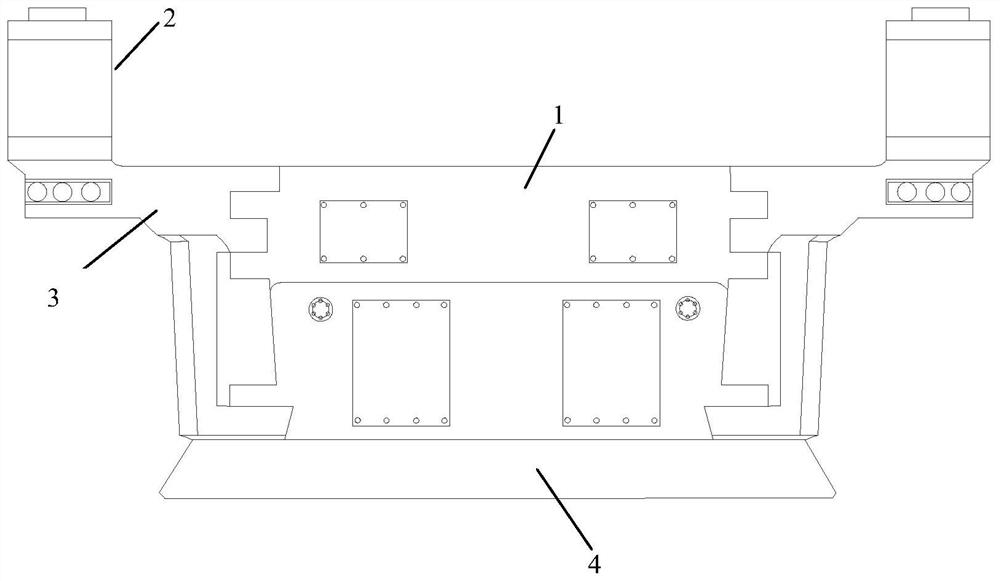

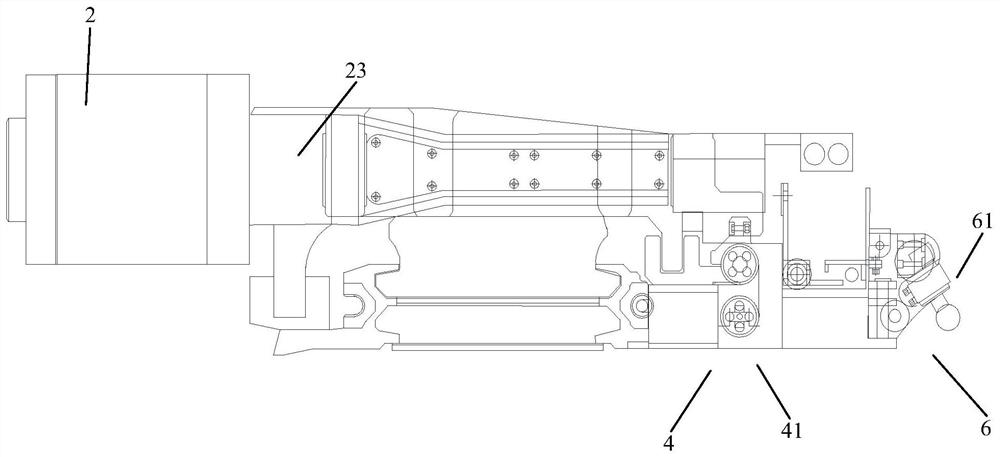

[0030] As shown in the figure, a hydraulically driven thin coal seam shearer 1 of the present invention includes a cutting part 2, a shearer rocker arm 3, and an outer traction walking part 4; the cutting part 2 includes a coal mining drum 21, Hydraulic motor 23; the hydraulic motor 23 is provided with an output shaft 22, and the hydraulic motor 23 is connected to the coal mining drum 21 through the output shaft 22; the hydraulic motor 23 is connected to the external connection through the hydraulic oil pipe 5 The pump station is connected; the cutting part 2 is rigidly connected with the rocker arm 3 of the coal mining machine. The hydraulic motor 23 is a low-speed high-torque hydraulic motor with a diameter of 450mm-1350mm, a torque of 7000 Nm-1 million Nm, and a speed of 10r / min-100r / min. The hydraulic motor 23 can also be connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com