Vertical wire rod feeding system

A vertical, wire rod technology, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve problems such as difficult control, high failure rate, and large wire status changes, and achieve the effect of improving the start-up rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to better understand and implement the technical solutions of the present invention, some embodiments of the present invention are provided here. These examples are for better explaining the technical solutions of the present invention, and do not constitute any form of limitation to the present invention.

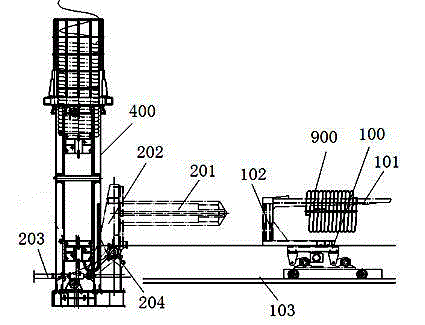

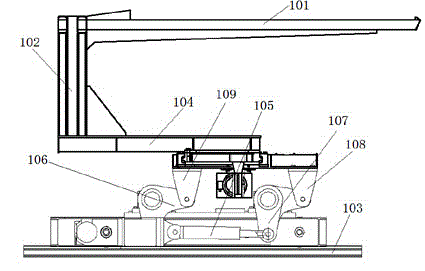

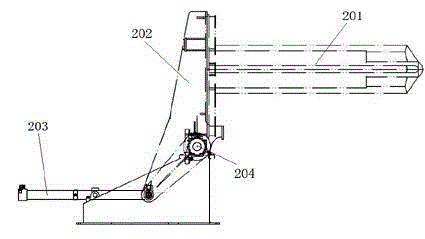

[0013] The wire vertical feeding system is used for wire feeding. The wire vertical feeding system includes a take-up and delivery device, an overturning device, and a lifting device. The take-up and delivery device sends the material roll to the overturning device After the overturning device is overturned, the material roll will be turned over, and the lifting device will lift the overturned material roll. The coil fetching device includes a trolley provided with a forward and backward drive device, and the column is rotated on the trolley. The arm a and the trolley are provided with a lifting device that drives the cross arm a up and down. The cross arm a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com